High confinement waveguide on an electro-optic substrate

a high confinement waveguide and electro-optic substrate technology, applied in the direction of optical waveguide light guide, optical elements, instruments, etc., can solve the problems of limited electro-optic effect, reduce the mode size of portions, and improve the mode size matching to optical fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

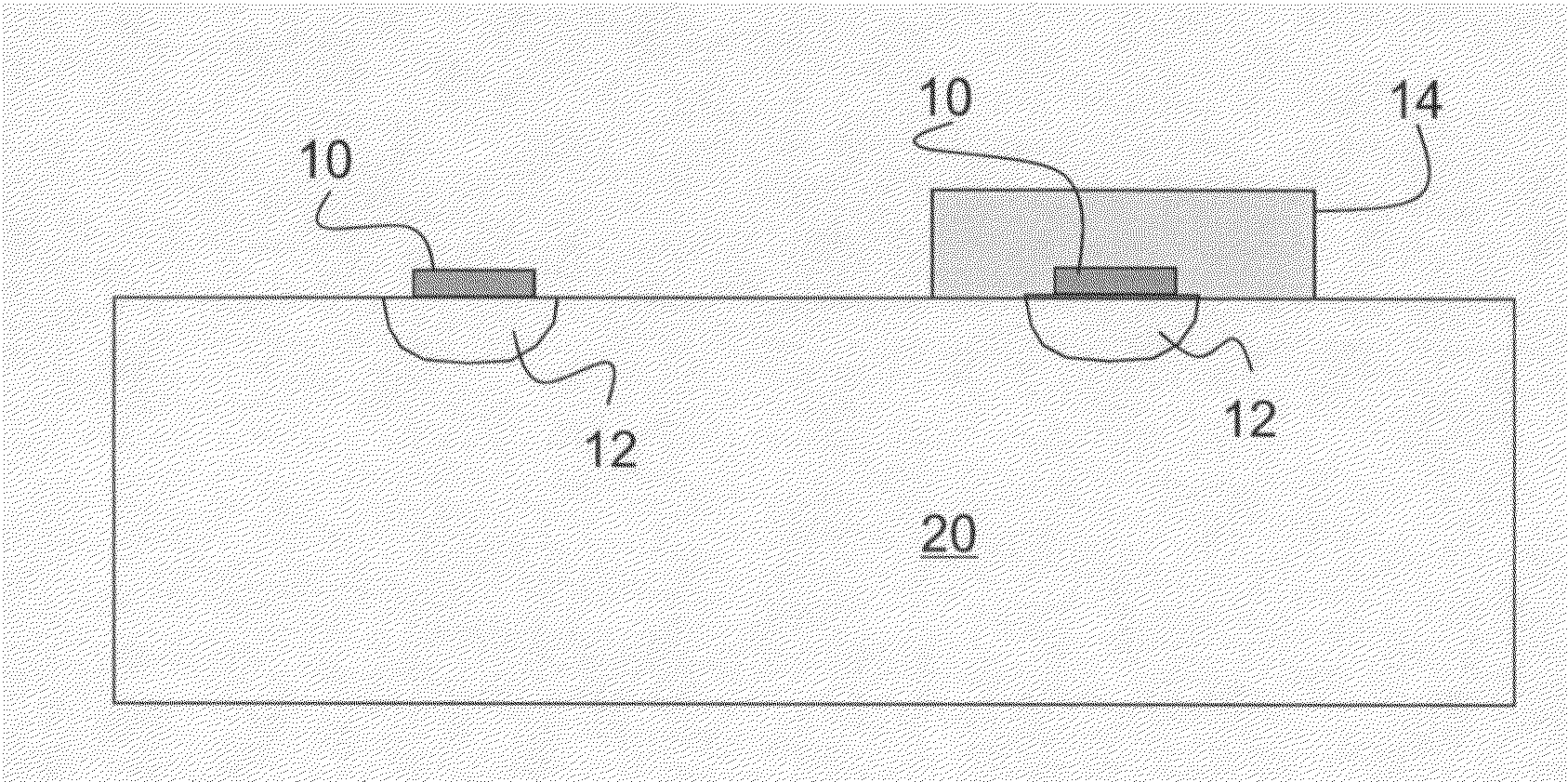

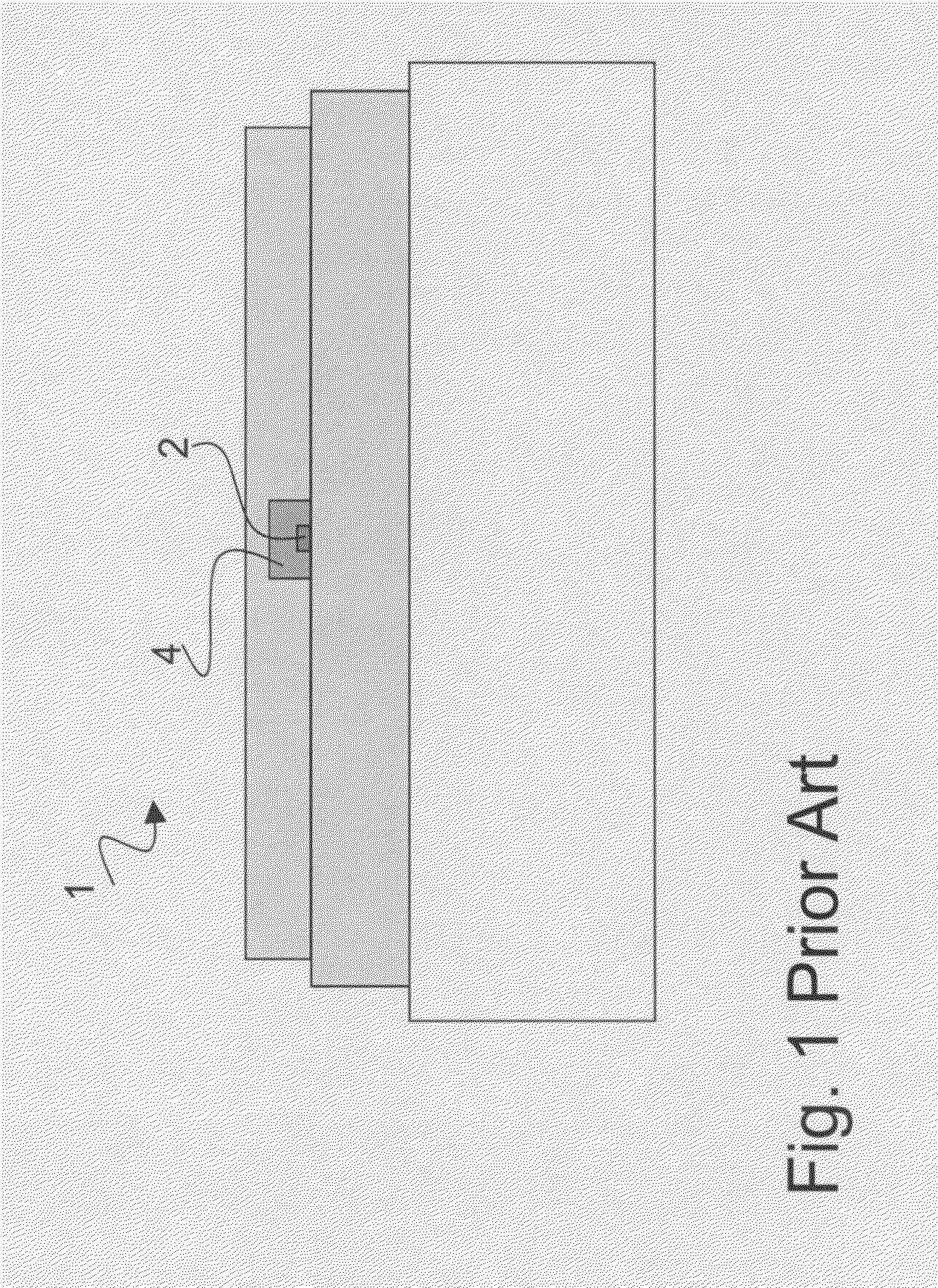

[0055]FIGS. 4-31 describe various embodiments of the invention, which consist of a high confinement waveguide, like SiN:Si, formed on top of an electro-optic material, like lithium niobate (LN). FIGS. 4-6 show the cross sections of different types of SiN:Si-on-LN waveguides. The SiN strip 10 is made to be rich in Si, increasing its optical index of refraction to be slightly higher than the optical index of LN 20. A high confinement waveguide must have an index change relative to the electro-optic substrate that is significantly larger than that created in the diffused waveguide. The maximum refractive index in a diffused waveguide in lithium niobate is typically 0.01 to 0.02 higher than the substrate index or said another way, the index change forming the waveguide is less than 1% of the substrate index. Furthermore, the average index change in most of the waveguide is less than the maximum index change as a result of creating a waveguide with a diffusion process, hence the average ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com