Anti-Rotation Feature for an Engine Tappet

a technology of anti-rotation and engine tappet, which is applied in the direction of valve arrangement, fuel injection apparatus, charge feed system, etc., can solve the problems that it has not been proved economical to provide a non-rotation flat in the engine bore, and achieve the effect of improving wear resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

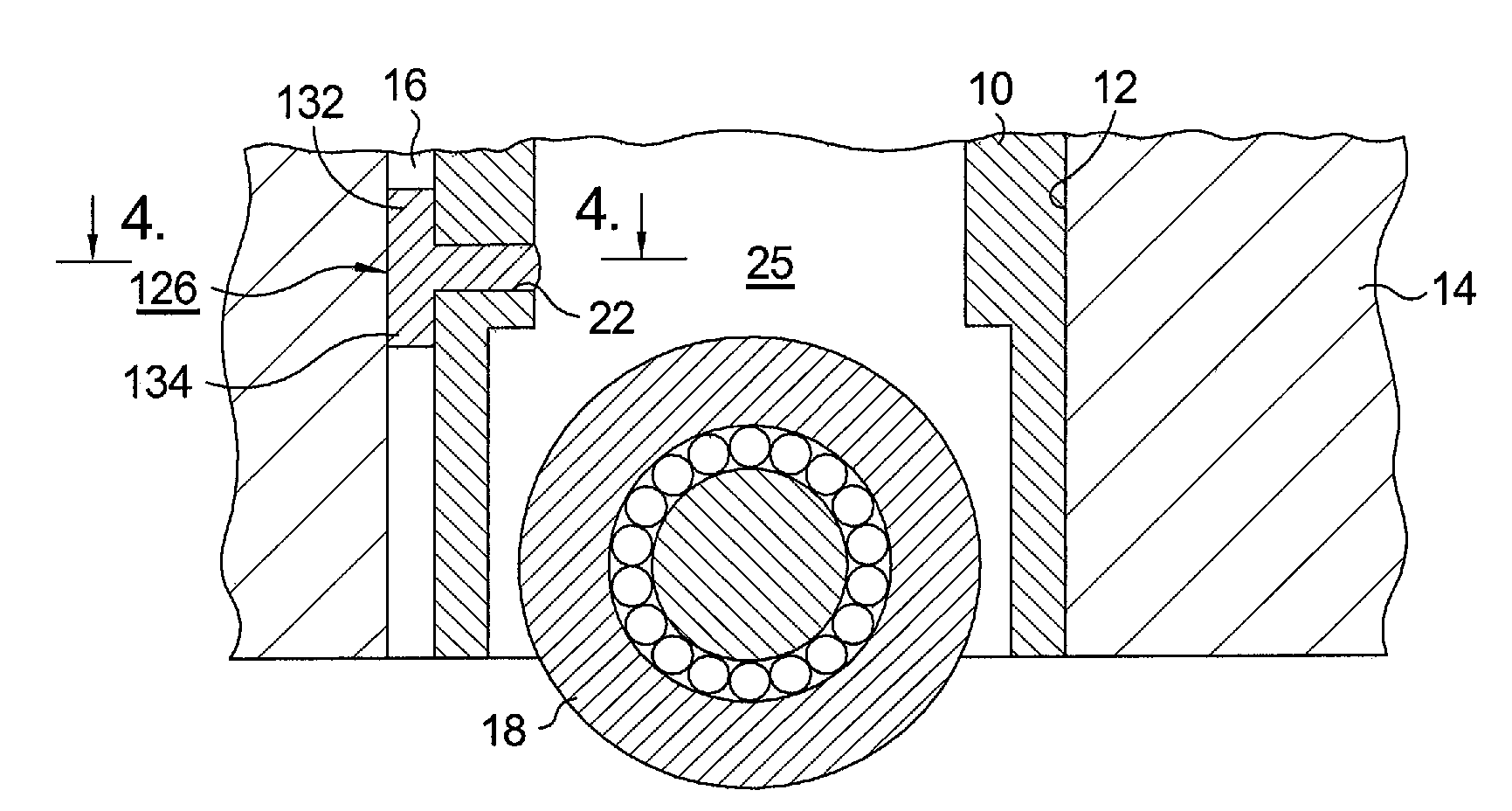

[0015]Referring to FIG. 1, a tappet 10 is slidably disposed in a bore 12 in an engine 14. Longitudinally adjacent and parallel to bore 12 is an anti-rotation channel 16 opening into bore 12. Tappet 10 is provided with a roller 18 for riding on the surface of a camshaft lobe 20 and a transverse hole 22 extending through wall 24 into a chamber 25. In accordance with the prior art, a close-fitting hardened pin 26 is press-fit into hole 22 and extends into channel 16 to prevent rotation of tappet 10 within bore 12, thus maintaining alignment of roller 18 on cam lobe 20.

[0016]The problems inherent in this prior art arrangement, which are eliminated by the present invention, are discussed above.

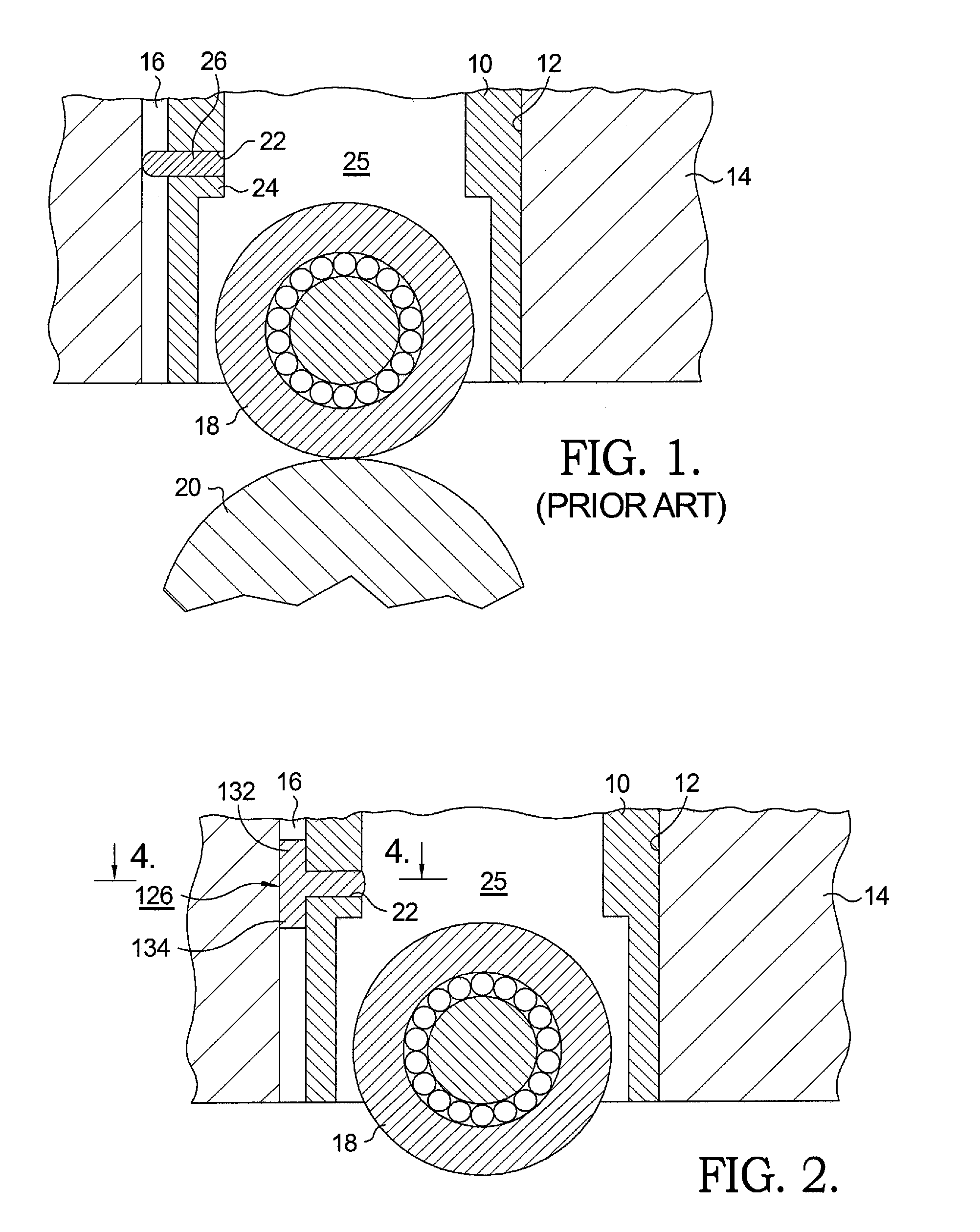

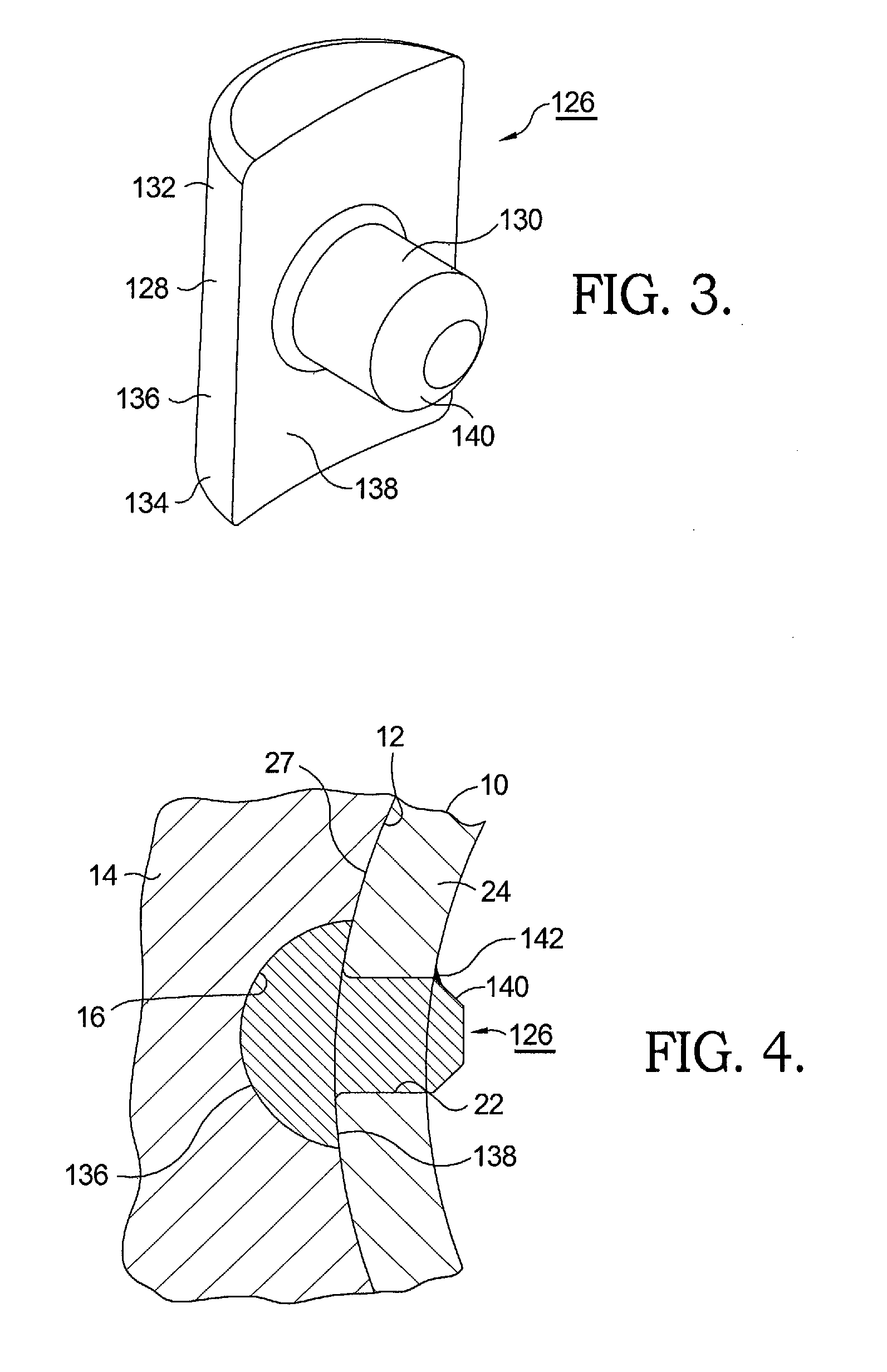

[0017]Referring now to FIGS. 2 through 4, an anti-rotation feature 126 in accordance with the present invention replaces prior art pin 26. Feature 126 comprises a first portion 128 for extending outwards from the surface of a tappet into channel 16, which in the presently-preferred example is cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com