Artificial palm frond for an artificial palm tree

a palm tree and artificial technology, applied in the field of artificial palm fronds, can solve the problems of not being able to meet the high requirements, conventional artificial palm trees, and palm fronds which are not suitable for permanent use in outdoor areas, and achieves high flexibility in fabrication, easy handling and flexibly combinable, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

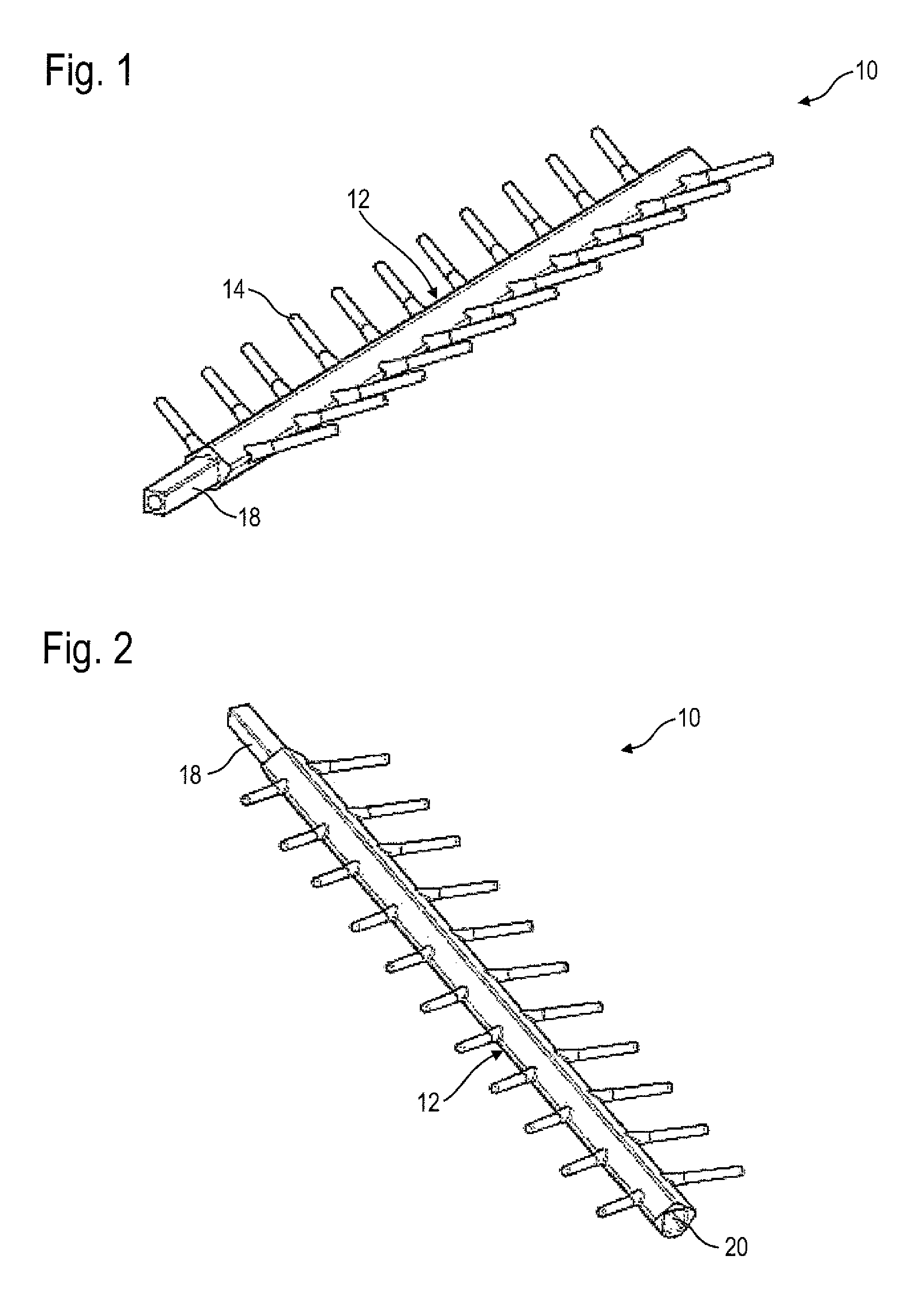

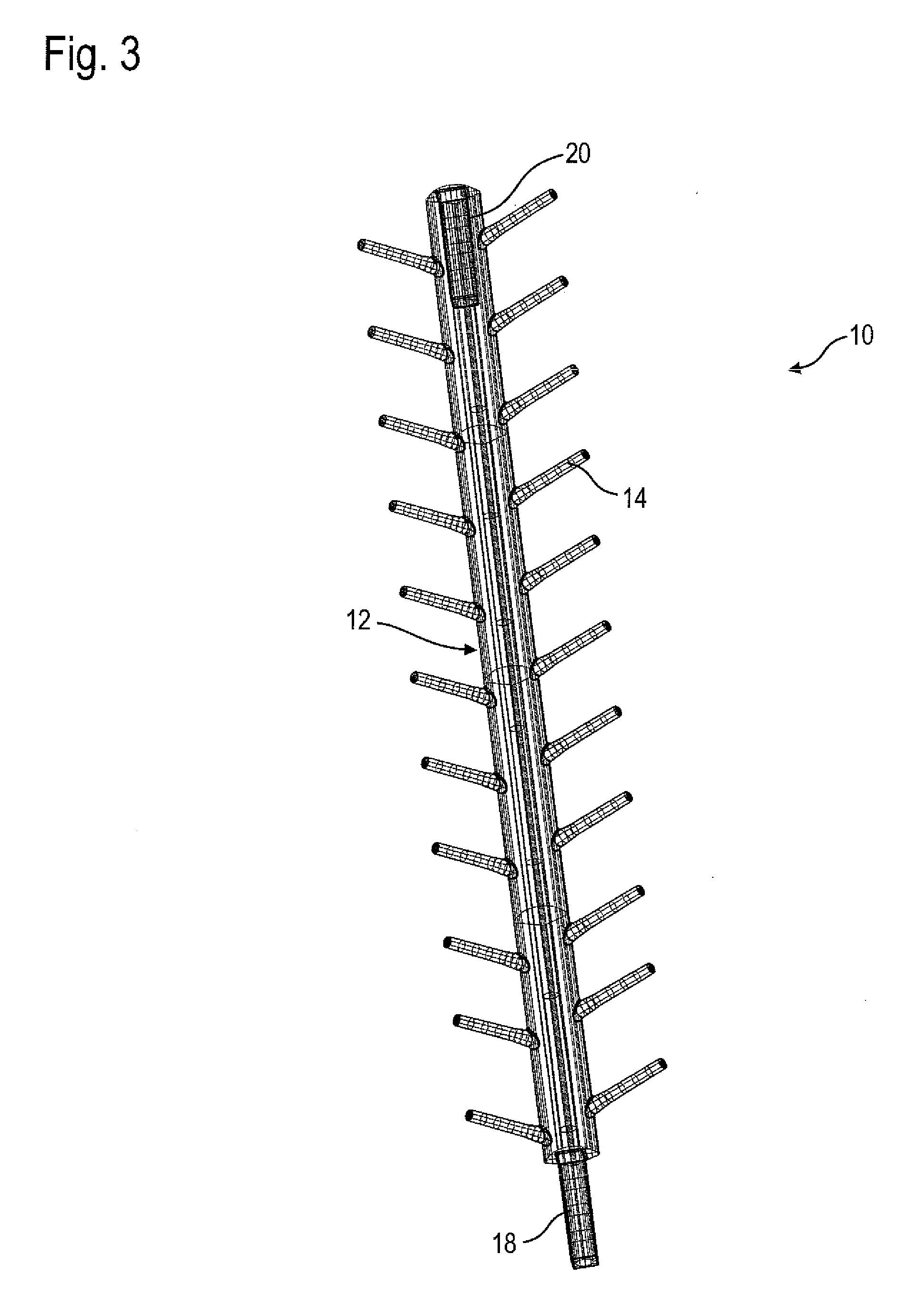

[0020]As illustrated in FIGS. 1 to 3, the stem component 10 for an artificial palm frond has an elongated base body 12 made of plastic, which is hollow inside and has two front-end openings. Thus, the base body 12 is suitable to be slided onto a pole.

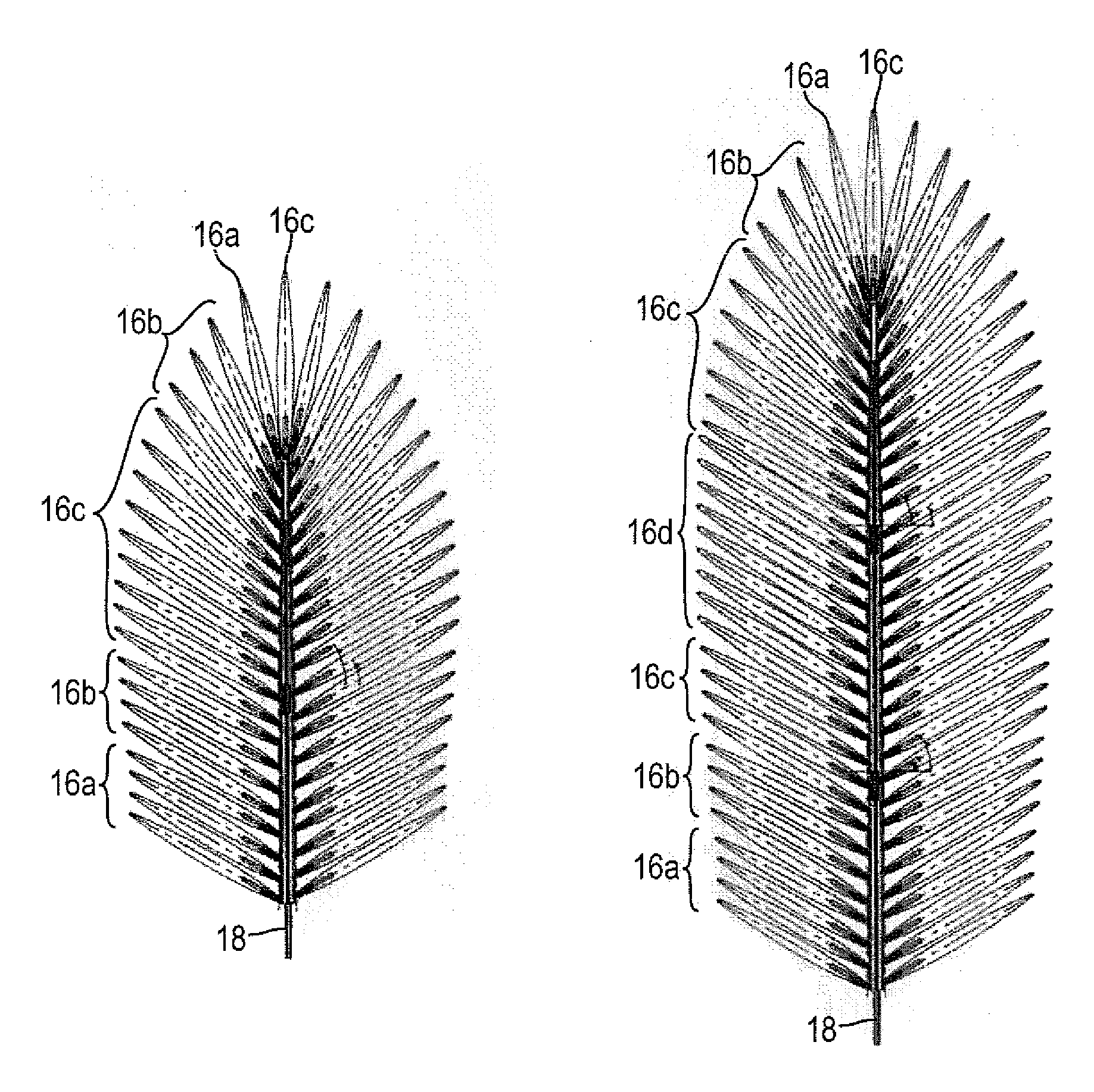

[0021]Integrally molded along the base body 12 are several nipples 14 provided for the attachment of artificial leaves 16 (see FIG. 5) which are made in one piece (more particularly by injection-molding), that is, the leaves are not adhesively bonded to an attachable support. The outer cross-sectional shape of the base body 12 and the arrangement and orientation of the nipples 14 are modeled on real palm fronds.

[0022]The base body 12 has a lower end including an extension 18 and an opposite, upper end including a mount 20. The extension 18 is provided for insertion into the mount 20, having the same length, of another base body 12. In this way, depending on the number of the stem components 10 placed axially in line with each other, pal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com