Pyramid Rebar Support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

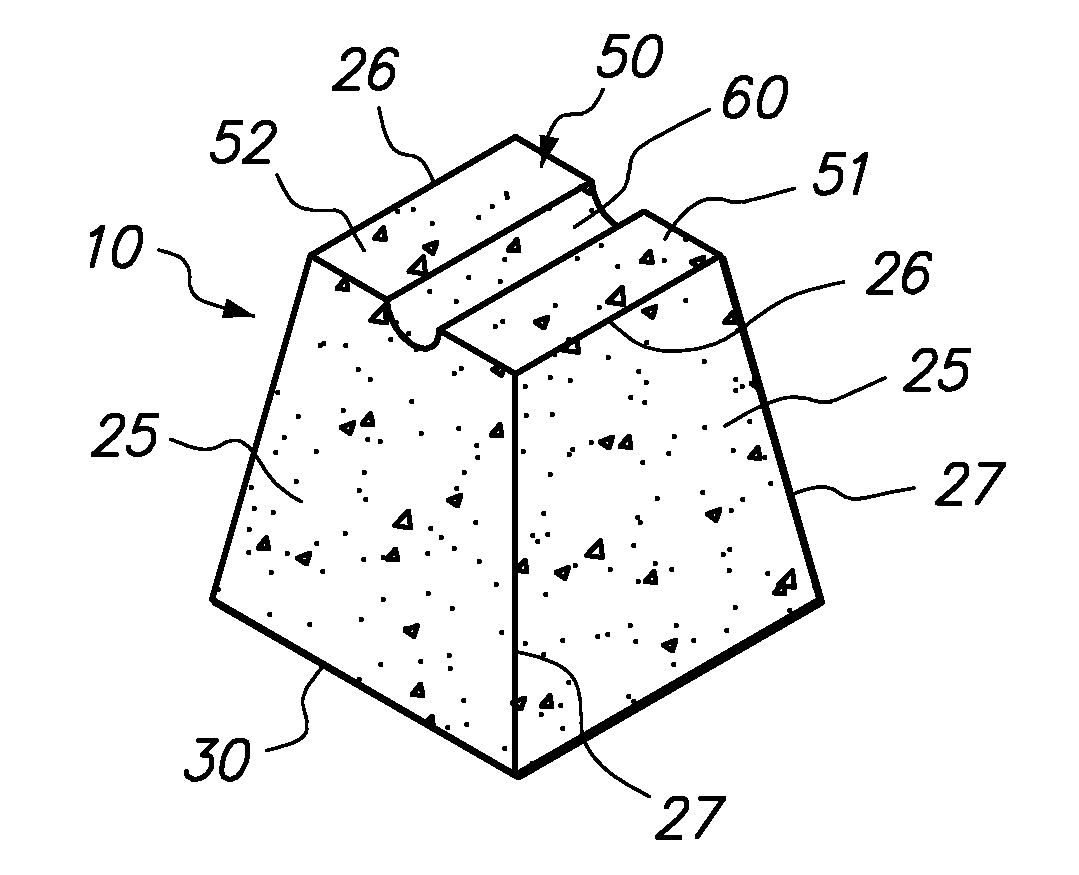

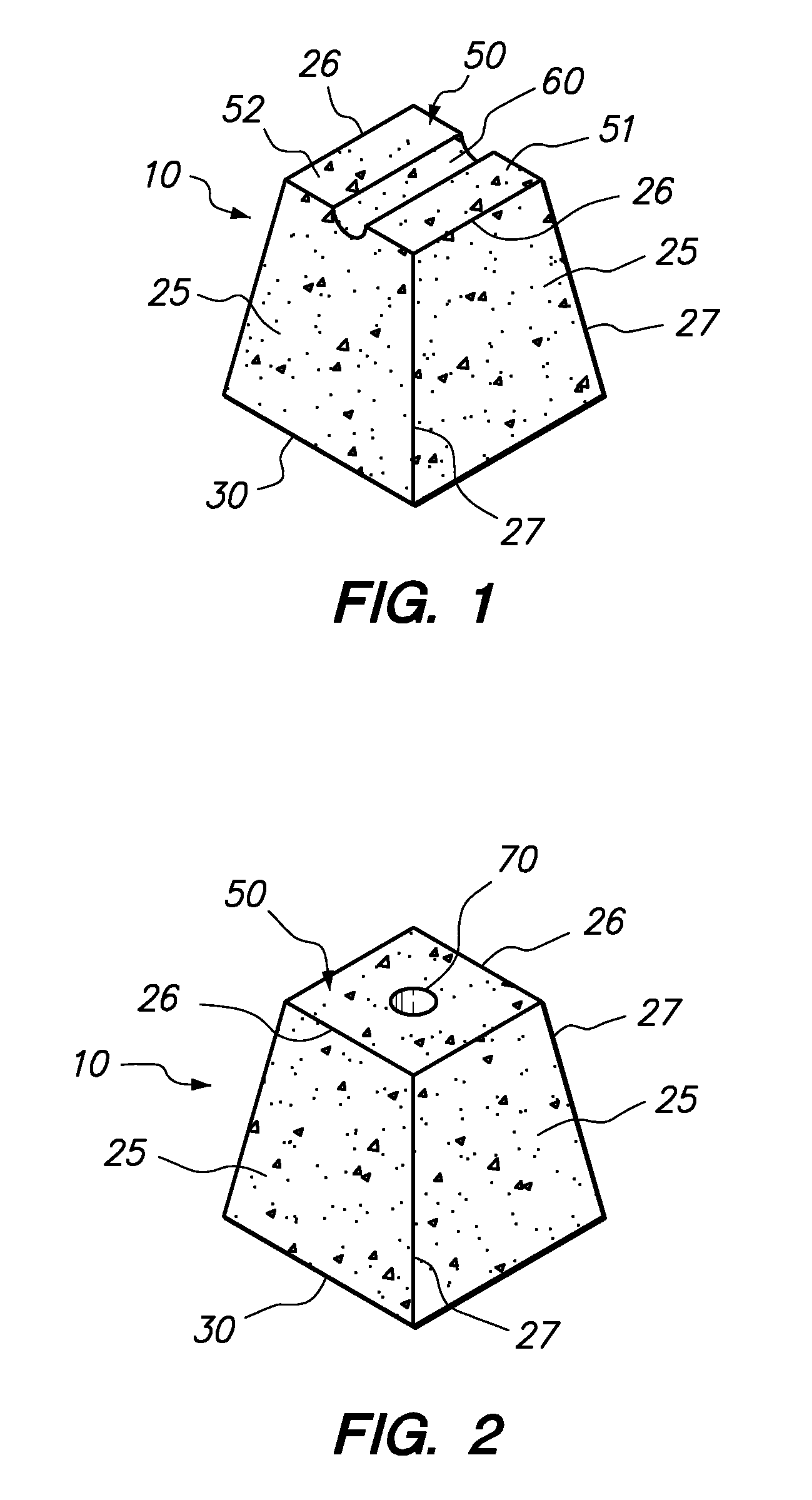

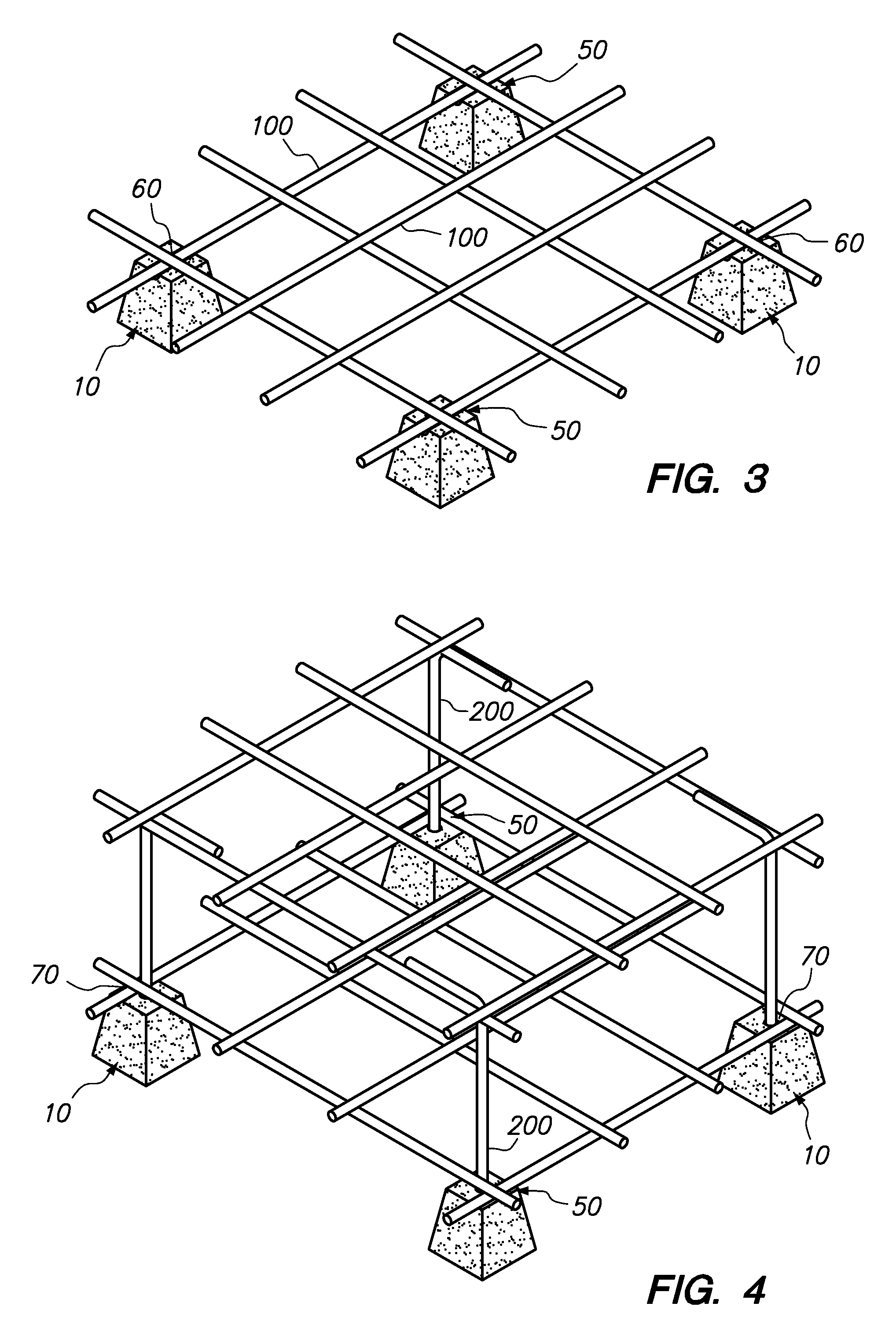

[0021]Referring now to the drawings, the novel reinforcement member support chair of this invention can be better understood by reference to FIG. 1. Illustrated inFIG. 1, a chair indicated generally at 10. The chair 10 includes a body consisting of four sloping walls 25, a flat, rectangular base 30, and a receiving area 50.

[0022]The base 30 is generally rectangular. The four walls 25 extend upwardly and inwardly from the base towards the receiving area 50. The walls 25 taper in width as they rise, resulting in a roughly pyramidal shape, until they terminate at the chairs top 26. The top 26 of the four sloping walls are joined along the four corner edges 27. In FIG. 1, the receiving area 50 has a flat top surface, which contains a pair of diametrically opposed, raised flat topped surfaces 51 and 52, which define a curved, open, central channel 60. Central channel 60 runs the length of receiving area and is sized for the receipt and retention of a reinforcement member, such as a post-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com