Evaporator for looped heat pipe system

a looped heat pipe and looped technology, applied in the direction of indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of limiting the formation of inner structures in the desired shape, heat transfer to the sintered wicks is not smooth, and the electrical components of the central processing unit or semiconductor chips used in various electronic devices such as computers generate a large amount of heat during operation, so as to improve the contact state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

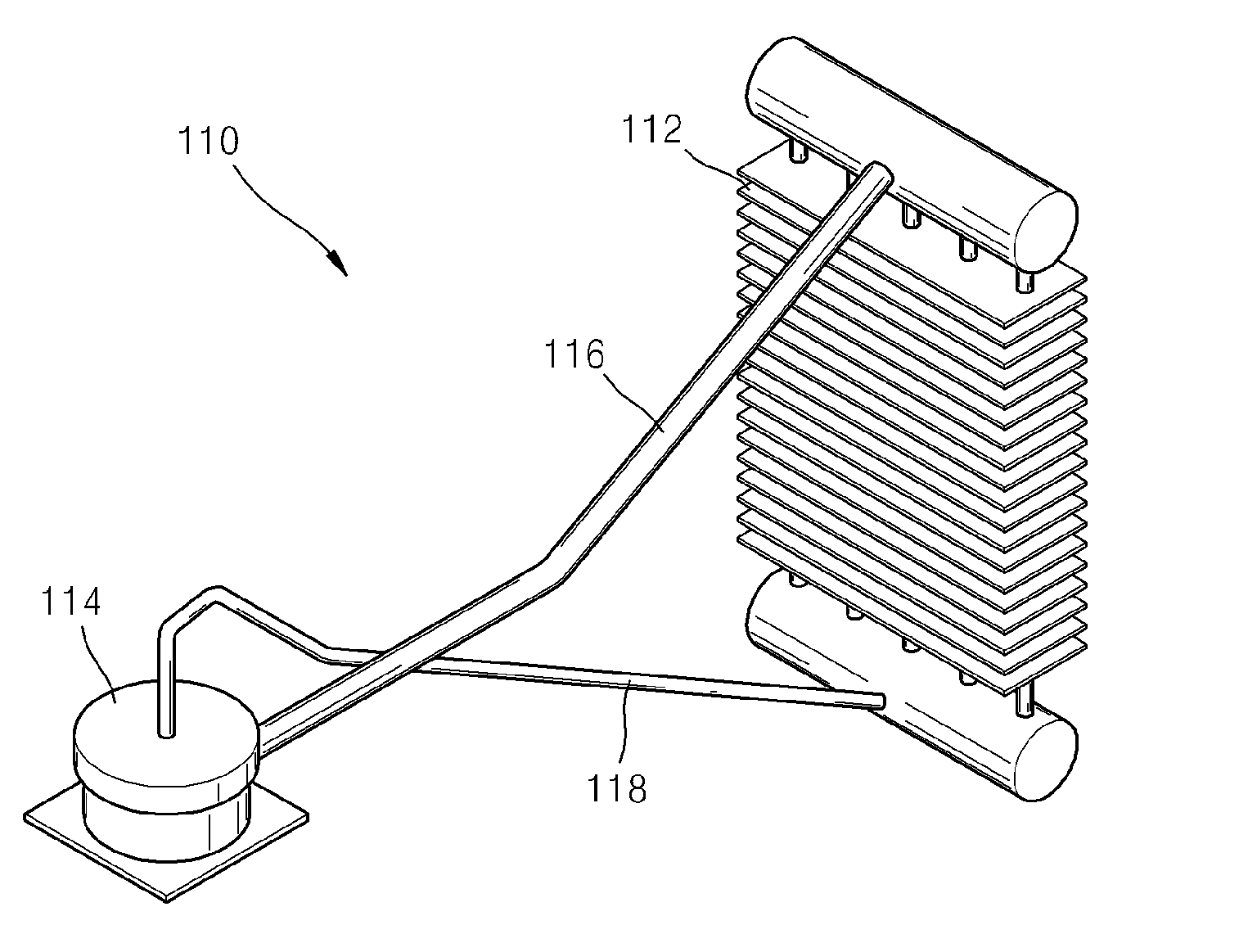

[0042]The present invention relates to an evaporator for a looped heat pipe (LHP) system including a condenser, a vapor transport line, and a liquid transport line.

[0043]Operations of the LHP system correspond to those described above in relation to the conventional technology.

[0044]A structure of an evaporator 1 for a LHP system according to an embodiment of the present invention will be described with reference to FIGS. 6 through 10. FIG. 6 is an exploded perspective view of the evaporator 1.

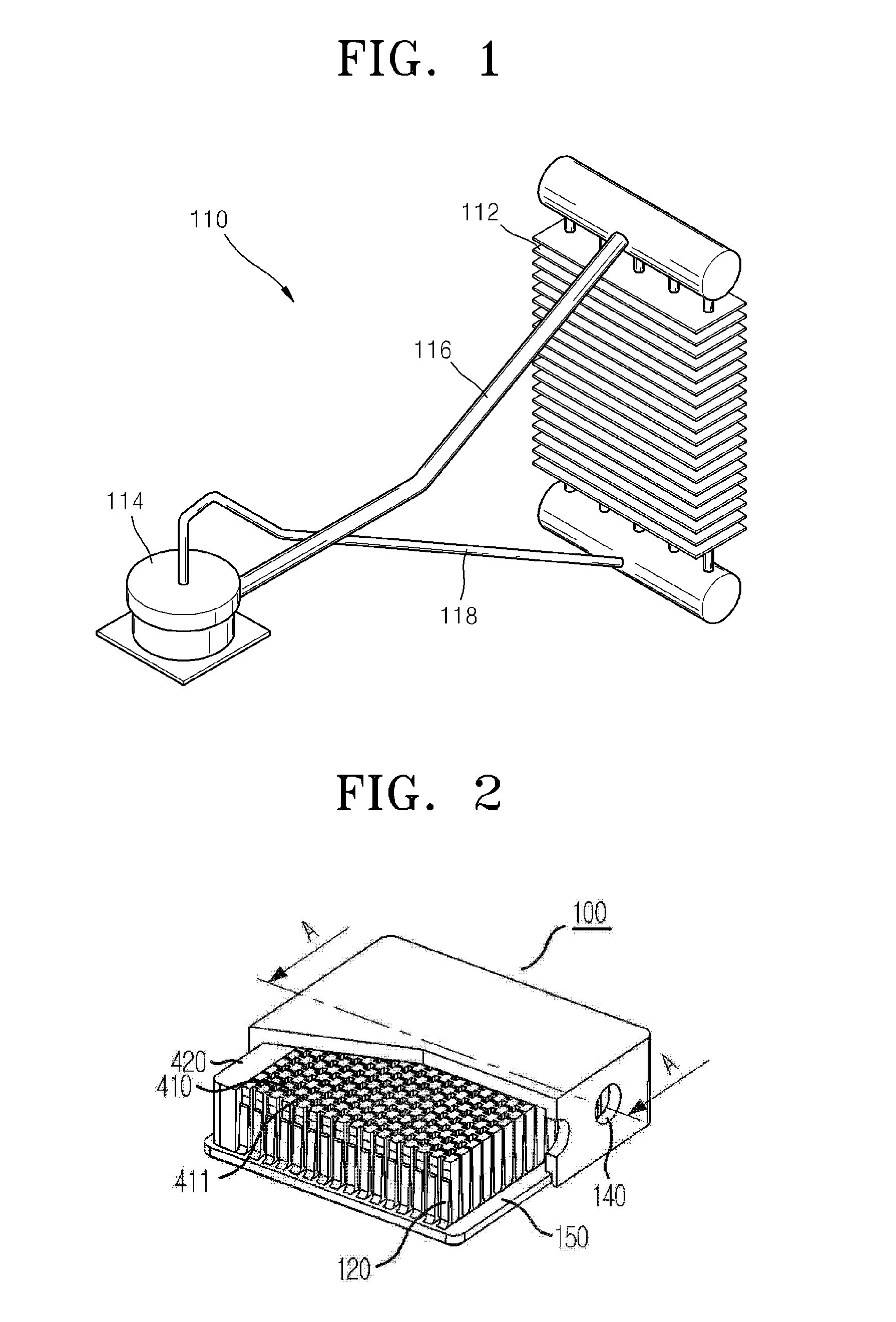

[0045]The evaporator 1 includes a plurality of wicks 10, a plurality of heat transferring fins 20, a unit assembly 30, an assembly structure 40, a heat transferring plate 50, and a cover member 60.

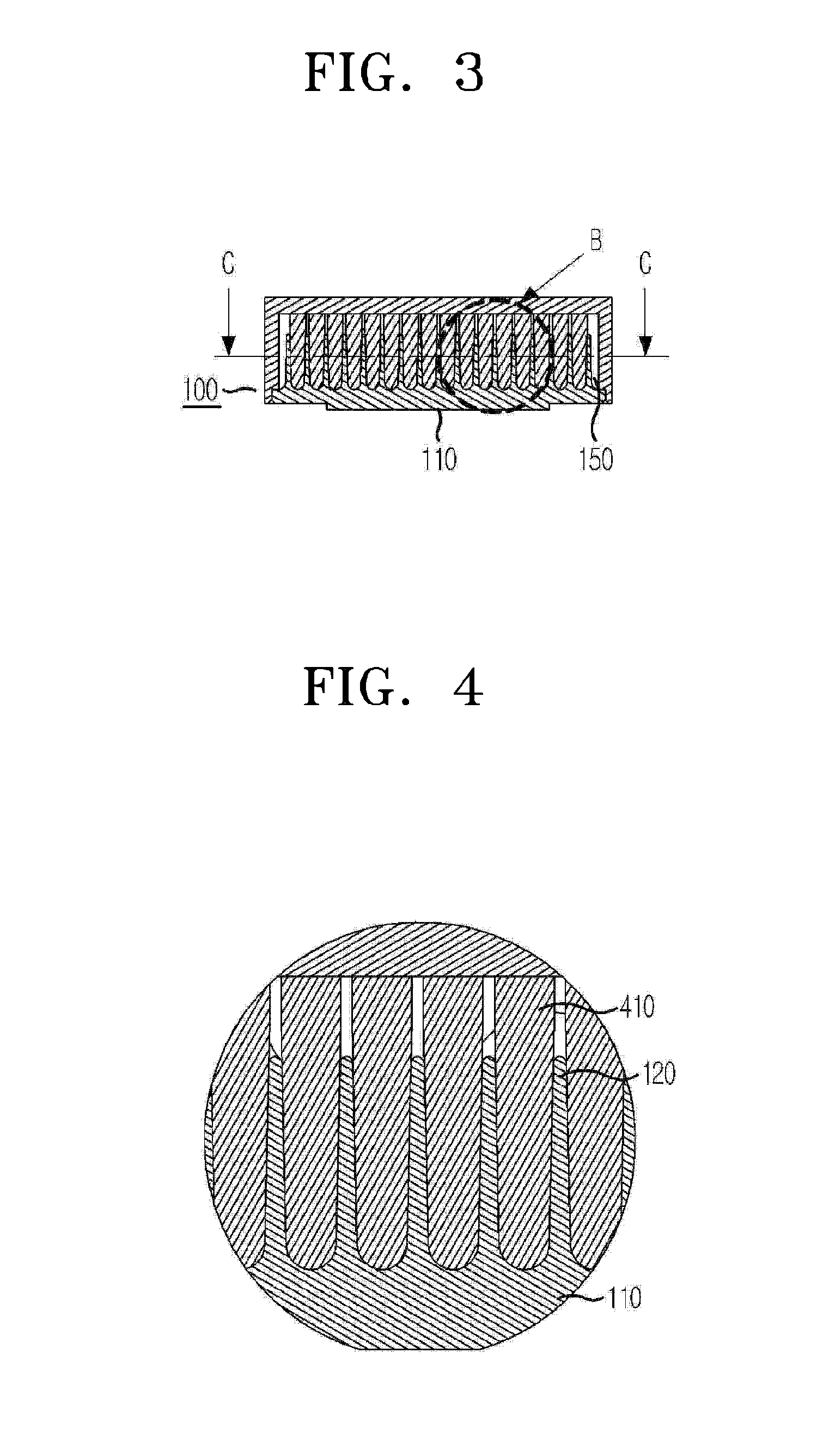

[0046]Referring to FIG. 7, each of the wicks 10 has a thin plate shape. The wicks 10 are respectively coupled to the heat transferring fins 20, and are horizontally disposed.

[0047]Each of the wicks 10 is a separate member, thus, it is easy to form the wicks 10 to have various shapes. The shape of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com