System and apparatus for supportive scaffolding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

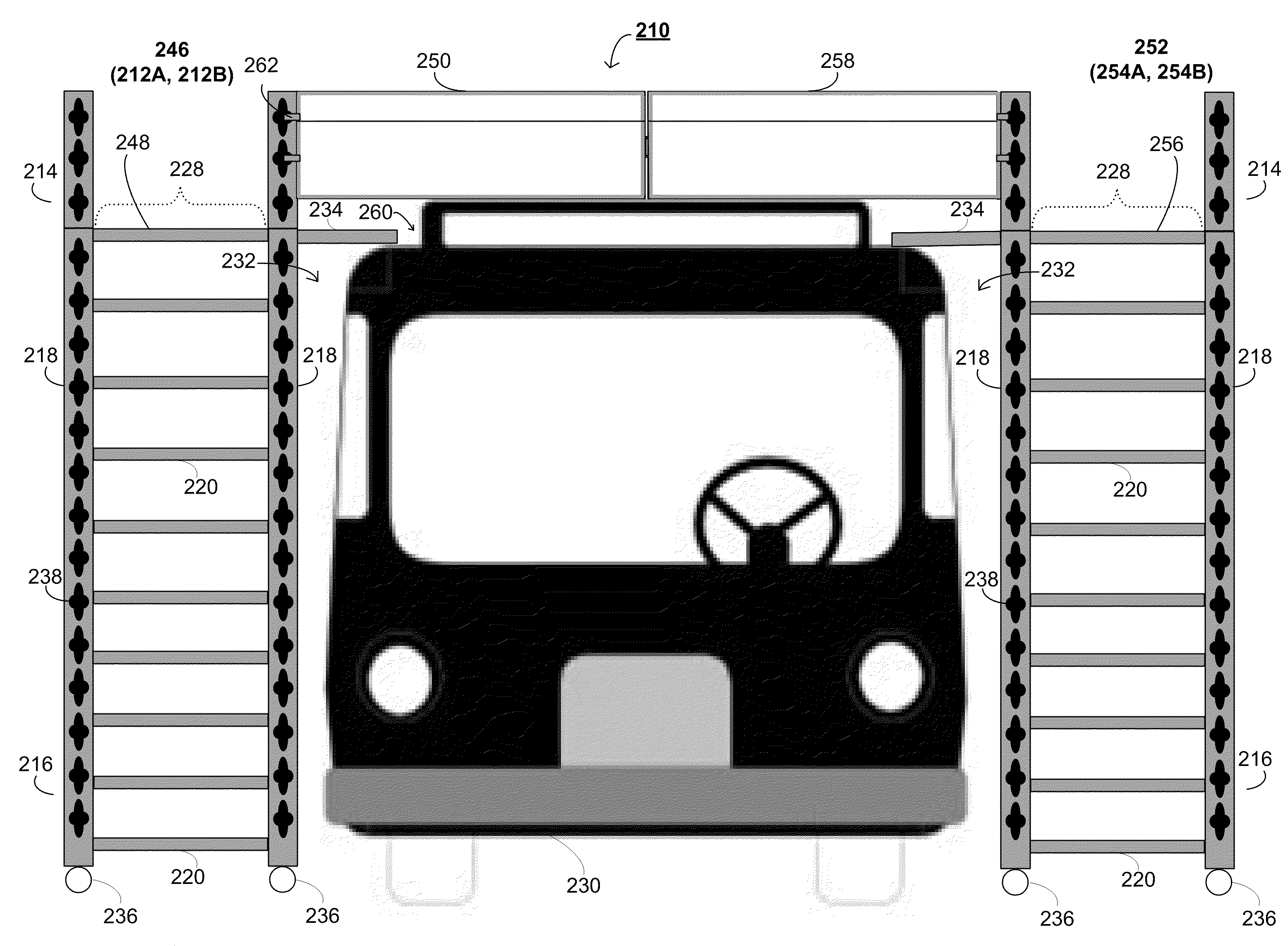

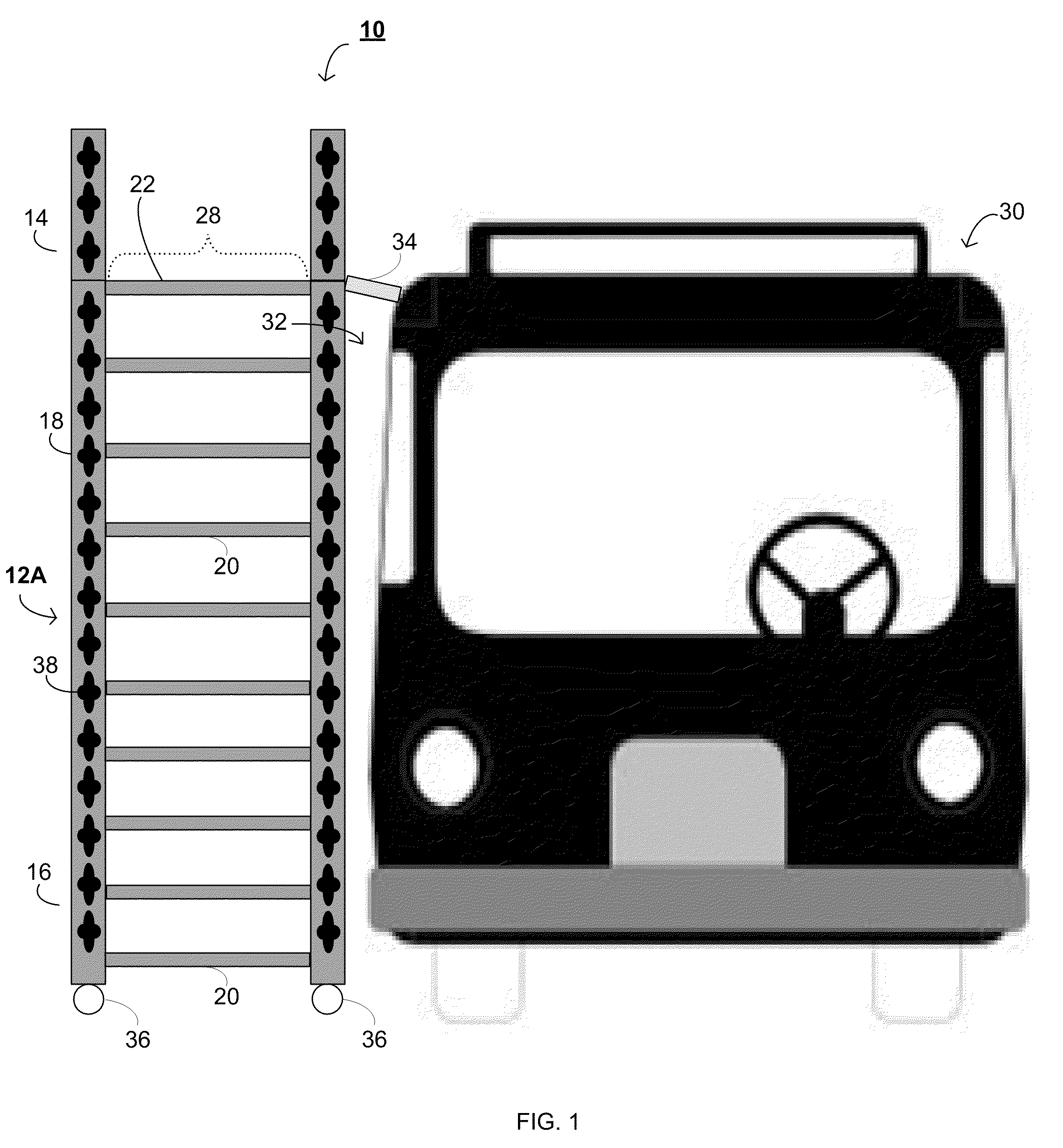

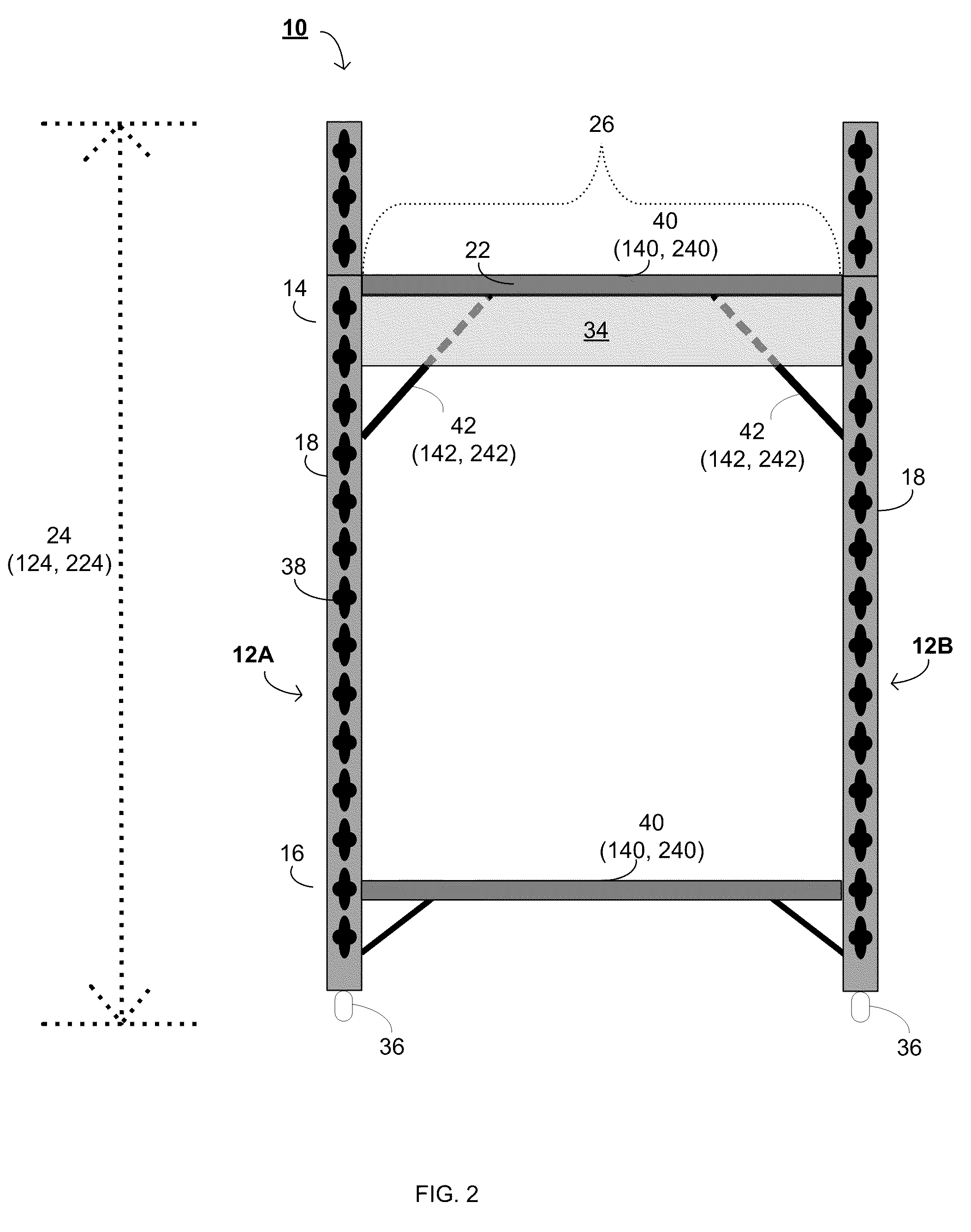

[0022]Referring to FIGS. 1 & 2, there is shown an embodiment of a scaffold system 10. The scaffold system 10 may include at least two essentially vertical support assemblies 12A and 12B having an upper end 14 and a lower end 16. Each of the essentially vertical support assemblies 12A and 12B may include at least two vertical support members 18 connected by at least one horizontal member 20. The vertical support members 18 may be composed of steel angles, and may be metal inert gas (MIG) welded together with the horizontal member 20. The horizontal member 20 may be composed of one (1) inch steel pipe.

[0023]The essentially vertical support assemblies 12A and 12B may also include a plurality of horizontal members 20. The horizontal members 20 may be configured to be attached to the vertical support members 18 to enable a user to access a platform 22. The horizontal members 20, when positioned along a height 24 of the vertical support members 18, may be configured to form a ladder. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com