Knitted-in-band

a knitted and banded technology, applied in knitting, pantyhose, textiles and paper, etc., can solve the problems of high discomfort of sculpting, inconvenient tight undergarments, and inability to wear tight undergarments, so as to reduce indentations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

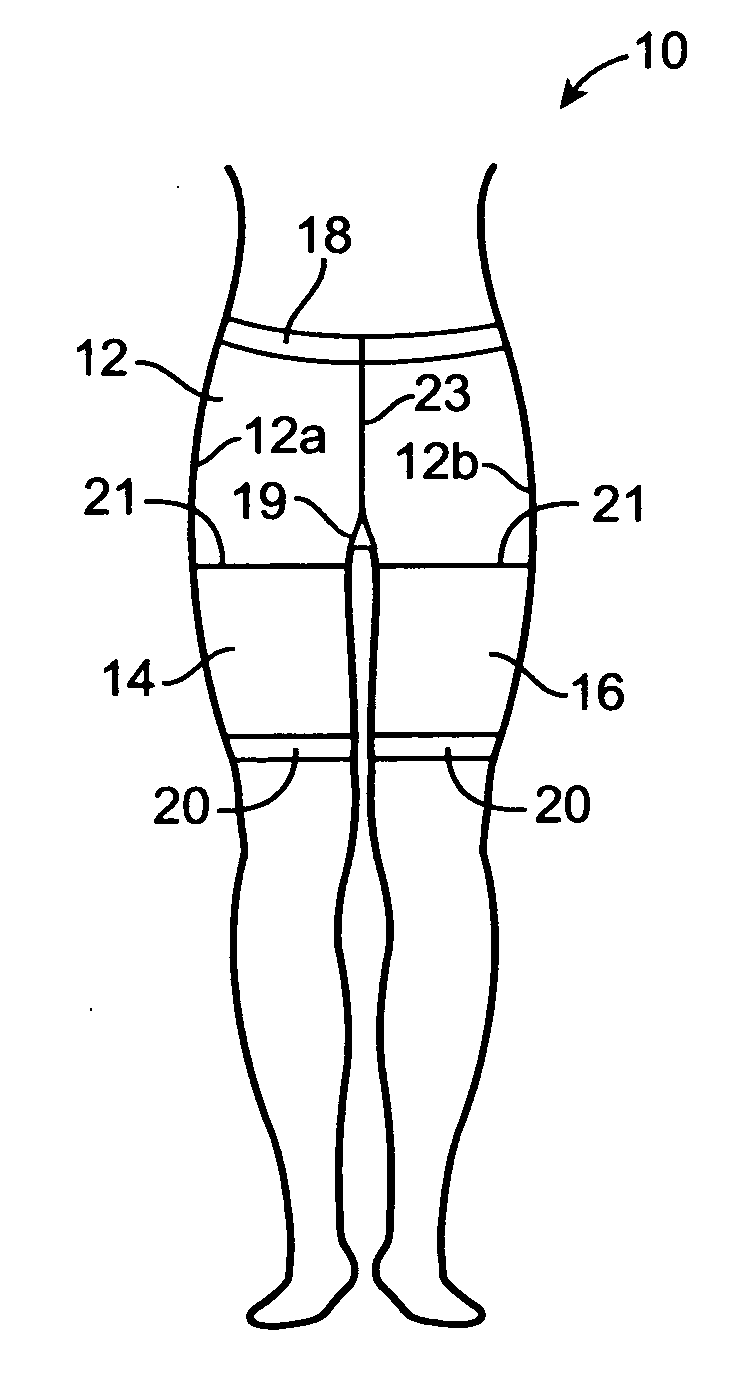

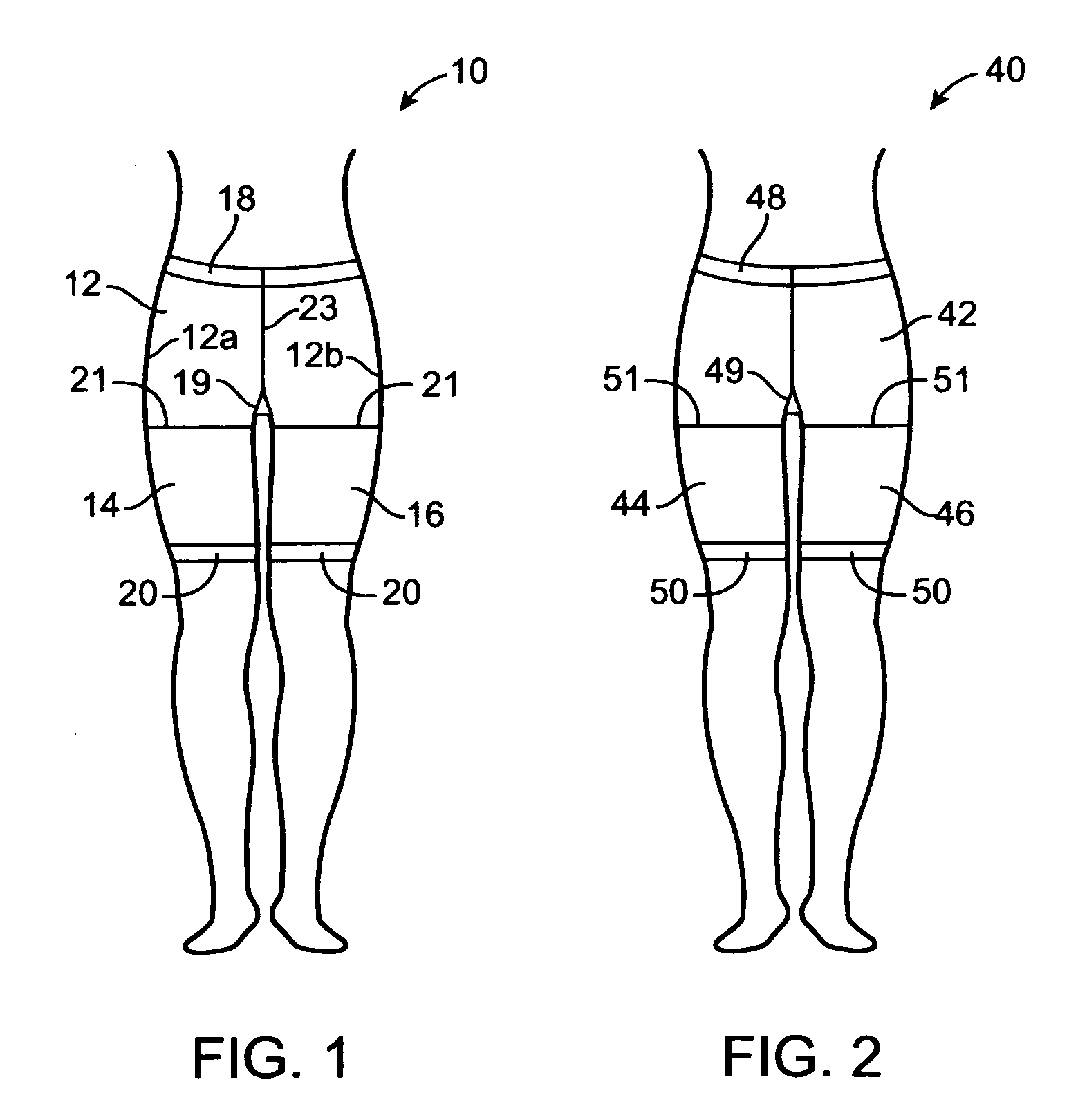

[0031]Referring to FIG. 1, there is shown a footless pantyhose undergarment or shapewear 10 of the present invention. The panty portion 12 covers the abdomen and the buttocks of the wearer and two leg portions 14 and 16 cover the legs. The panty portion 12 ends at a waist terminating portion 18, hereinafter referred to as waistband 18. The leg portions 14 and 16 end at their respective leg terminating portions 20, hereinafter referred to as leg bands 20. Each leg band is made of a two-ply knitted in band. However, the waistband 18 and leg bands 20 can be elastic bands, knitted-in welts, knitted-in bands, or can use any other knitting process which can create a terminating edge. Furthermore, the leg portions 14 and 16 are seamlessly knitted to the panty portion 12 along the line 21.

[0032]It should be noted that, unlike fashion hosiery, the footless pantyhose undergarment or shapewear discussed in this specification is strictly used as an undergarment and is not visible to the public....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com