Columnar downhole gas separator and method of use

a gas separator and column technology, applied in the field of gas separators, can solve the problems of addition of gas bubbles to the fluid, and achieve the effects of reducing the amount of gas bubbles, less chance of locking up, and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

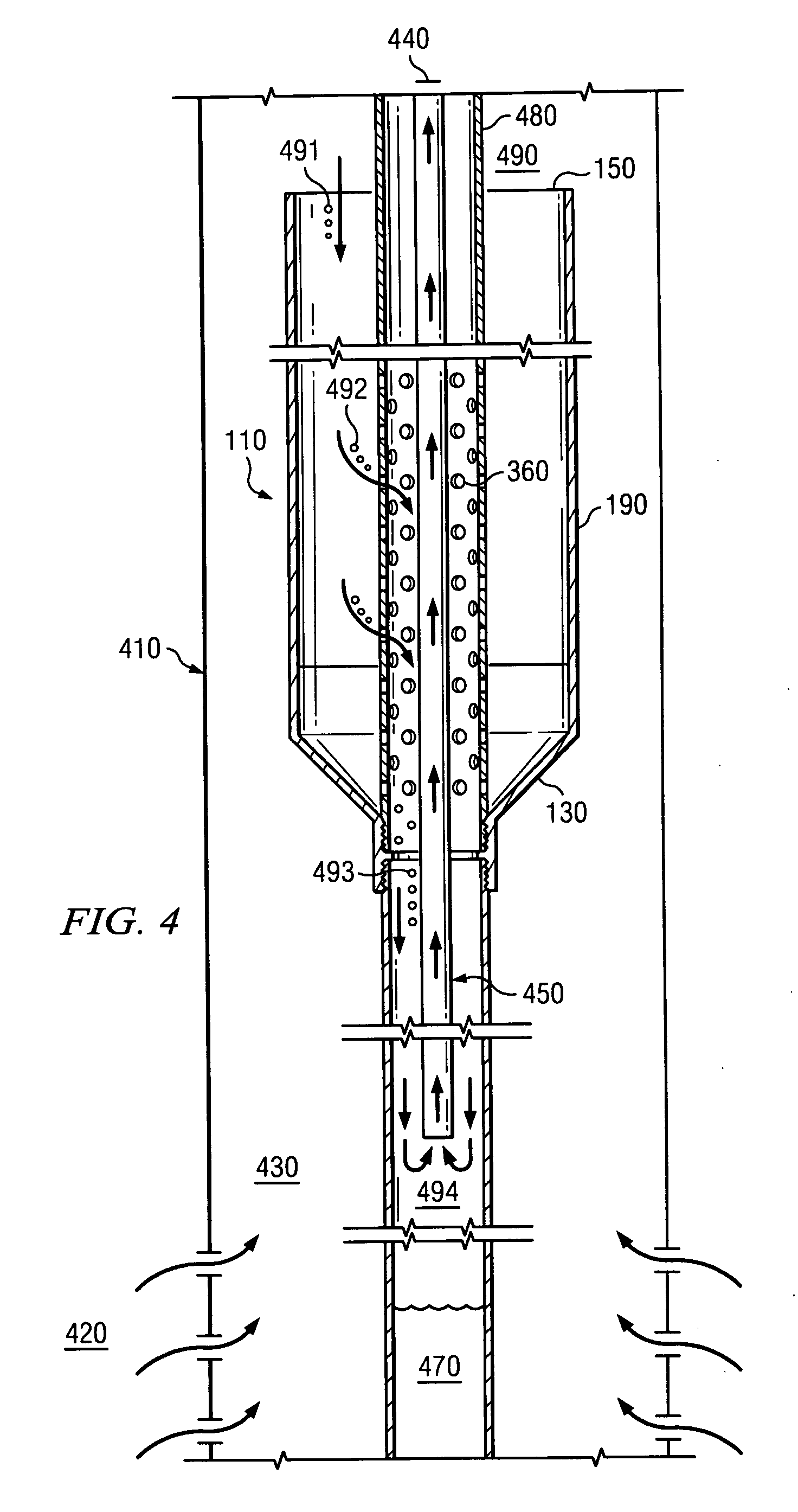

[0018]In the descriptions that follow, like parts are marked throughout the specification and drawings with the same numerals, respectively. The drawing figures are not necessarily drawn to scale and certain figures may be shown in exaggerated or generalized form in the interest of clarity and conciseness.

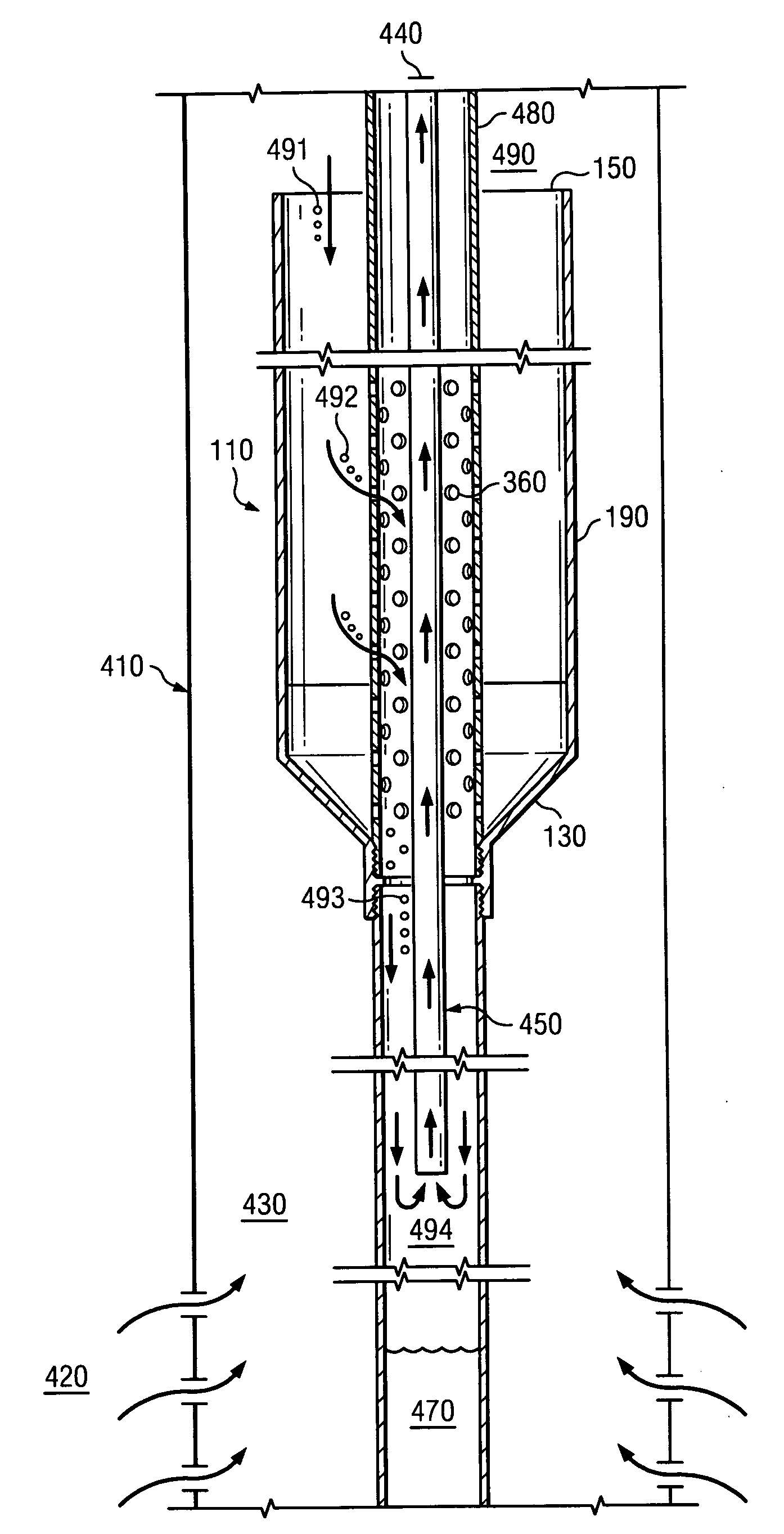

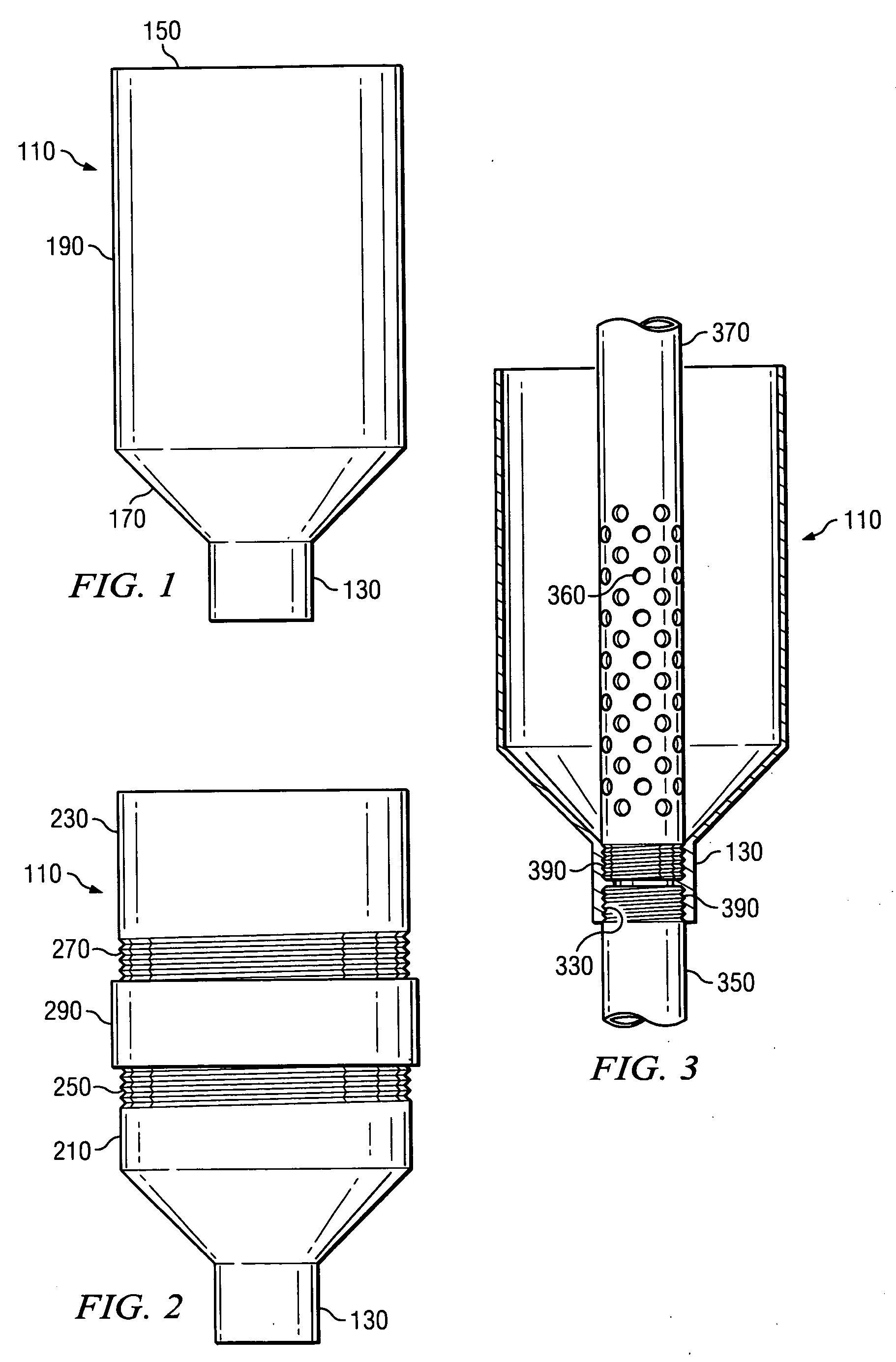

[0019]With Respect to FIG. 1, gas separator 110 is supported by a bell collar 130. Bell collar 130 is a cylindrical shape designed to support the gas separator by attaching to production pipe (not shown). Taper 170 is an angle between the bell collar 130 and the shroud 190. Shroud 190 causes mixed fluid to enter the gas separator 110 through the top opening 150 of the gas separator 110.

[0020]FIG. 2 shows the preferred embodiment of gas separator 110. Gas separator 110 consists of three pieces; a bell section 210, a collar 290, and a shroud 230. Shroud 230 has external threads 270. Additionally, the bell section 210 has bell collar 130. Bell collar 130 attaches to production pipe (n...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap