Winding group and method for winding paper around a core to make a log

a technology of winding group and core, which is applied in the direction of web handling, article delivery, thin material handling, etc., can solve the problems of limiting the “hold”, destroying the coupling of the core with the “initial edge”, and causing waste, etc., to achieve the effect of being convenient to use, cost-effective and particularly functional

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0047]Thus, in such FIGS. 5-8 the machine 10 comprises a connecting rod 71-crank 72 assembly in which the head of the connecting rod is defined by the guiding support 70 able to slide away from and towards the roller 14, through the effect of the crank 72, on suitable pins 73 or idle rollers. Of course, the movement of such a connecting rod 71-crank 72 assembly is synchronised with the production of the finished logs 11″ in such a way as to take the head 20 of the rod 17, always kept in rotation with respect to the pin 18, in contact with the paper 11′ moving forward on the roller 14 only upon the introduction of a new core 11 into the channel 12.

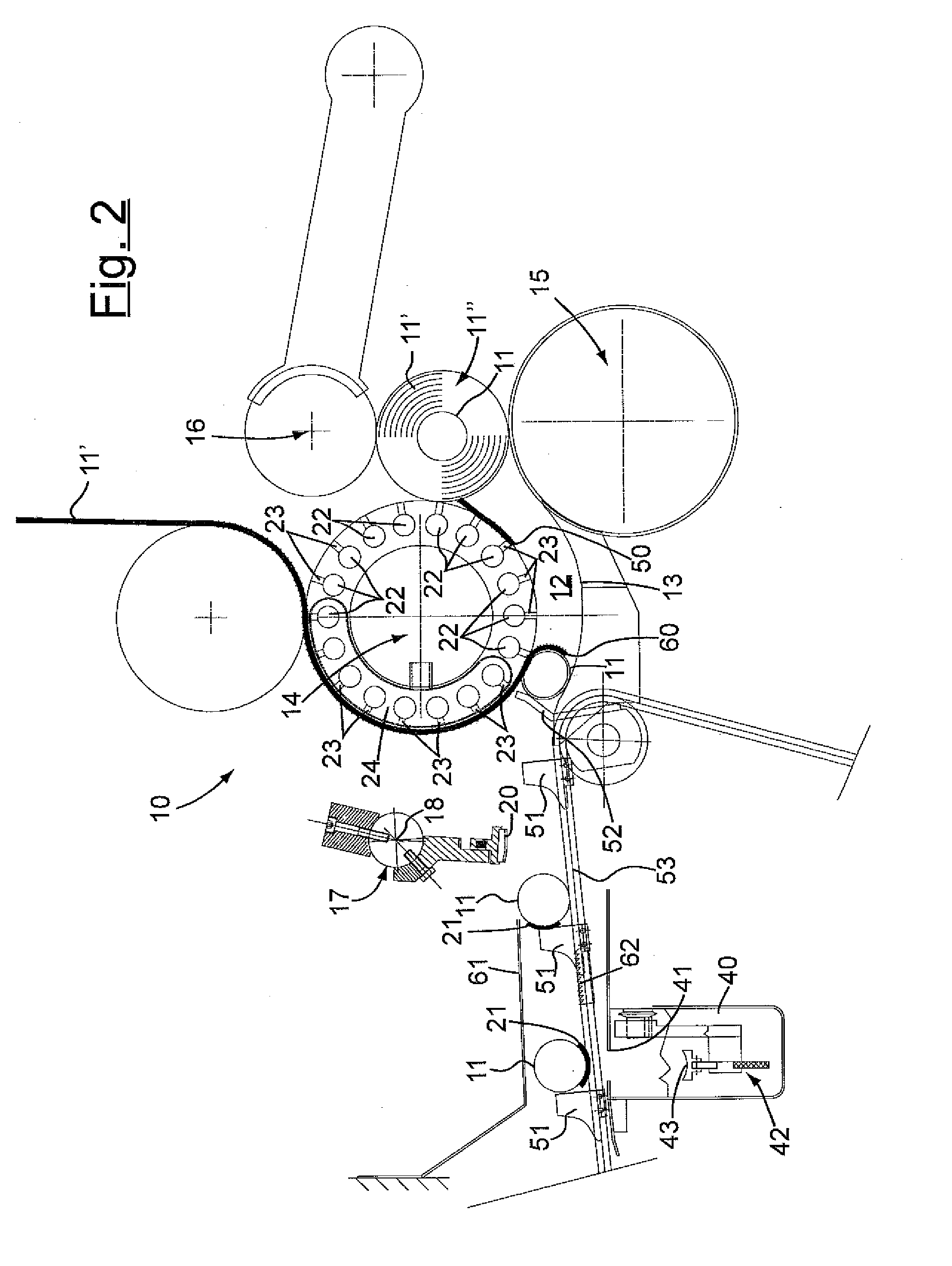

[0048]According to a preferred embodiment, shown in figures, the cyclic means for tearing the paper 11′ are arranged upstream of the channel 12 and cooperate with means for keeping the paper 11′ adhering around the upper winding roller 14 acting at least upstream of the channel 12.

[0049]Preferably, such means for keeping the paper 11′ act b...

first embodiment

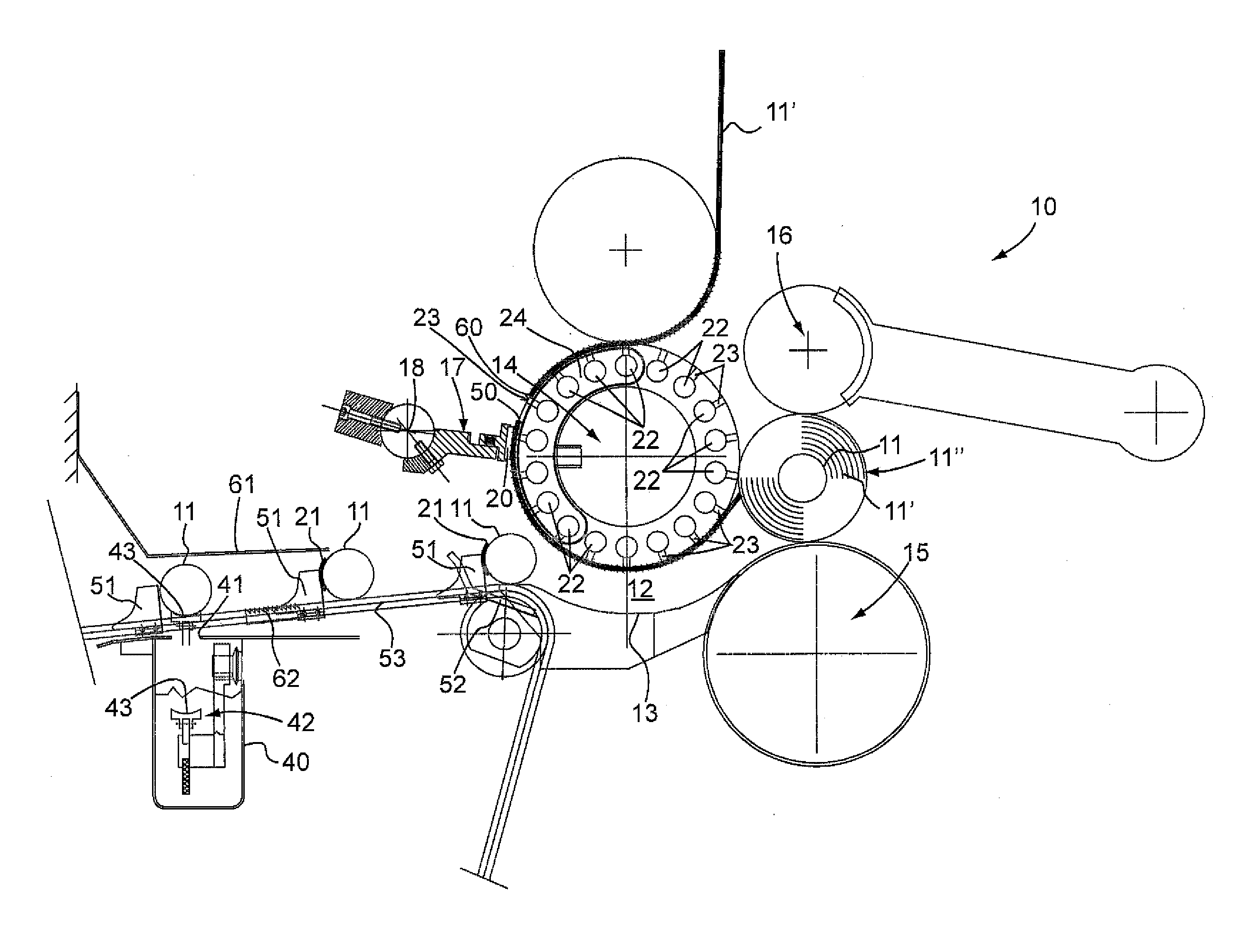

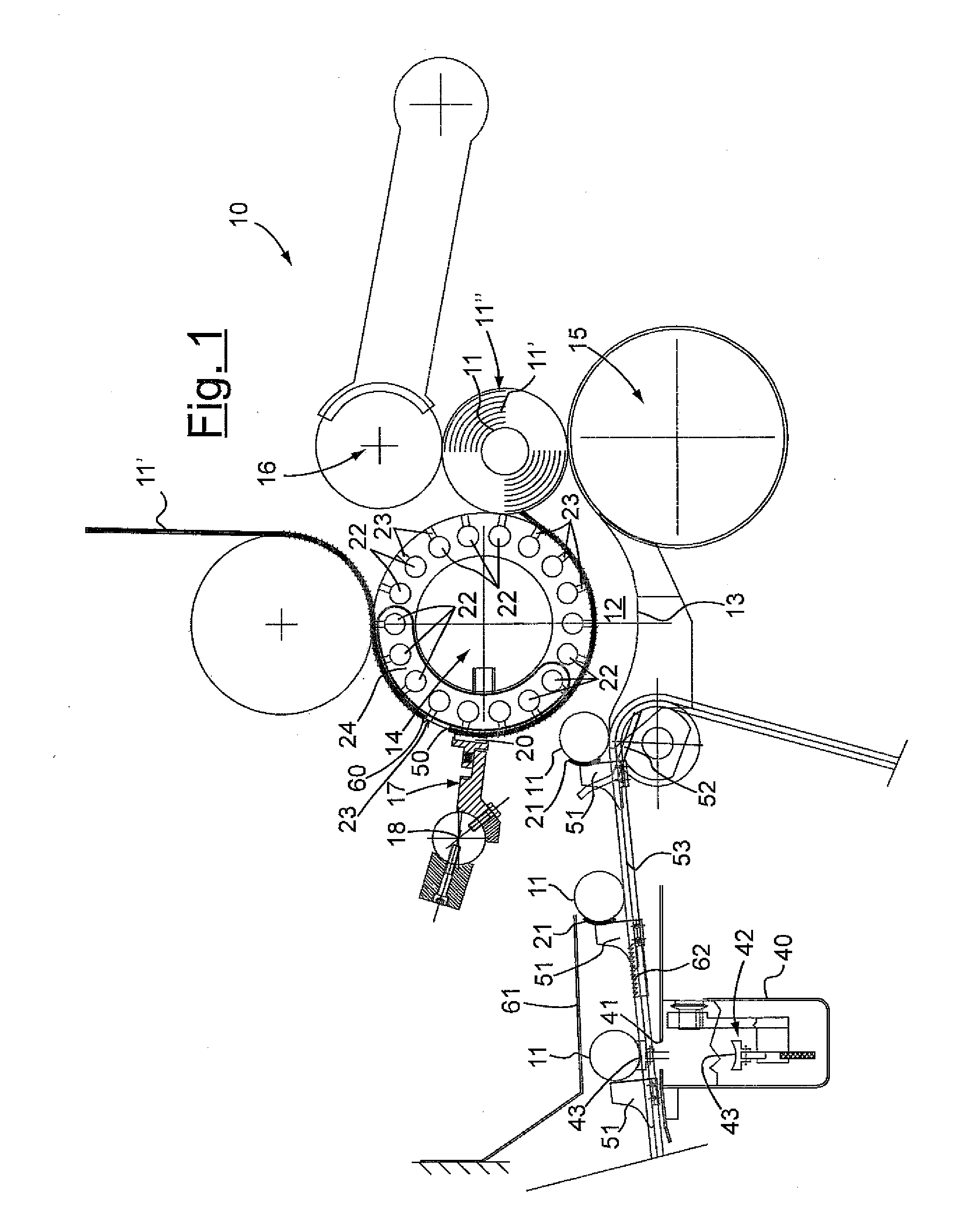

[0058]In a first embodiment shown in FIGS. 1-3 the aforementioned means to cause the winding comprise means for supplying glue 21 to the core 11 arranged upstream of the channel.

[0059]As can be imagined, such glue 21 during the journey of the core 11 in the channel 12 holds the initial edge 60, which proceeds on the roller 14 thanks to the suction means, ensuring safe winding of the paper 11′.

[0060]Alternatively, the means to cause the initial edge 60 to wind on the core 11 introduced into the channel 12 can comprise means for taking the initial edge 60 away from the upper winding roller 14 arranged at the channel 12 substantially downstream of the cyclic means for tearing said paper 11′ and of the suction shoes 24.

[0061]In particular, such means for taking away the initial edge 60 have the purpose of thrusting the initial edge 60 of the paper 11′ towards the lower portion of the channel 12 promoting its firm engagement on the new core 11 that is moving forward in the channel 12 tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com