Rotary seamer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

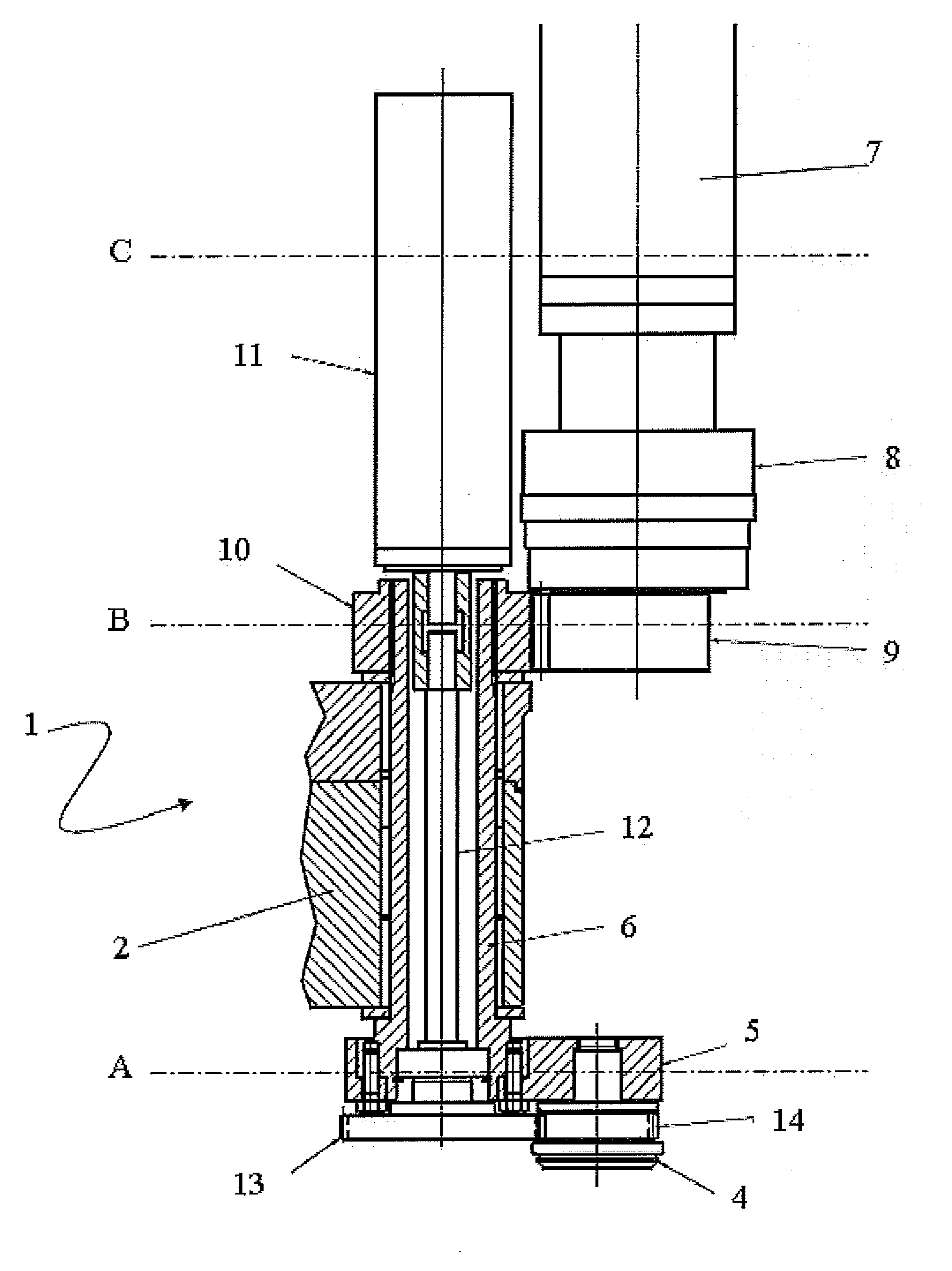

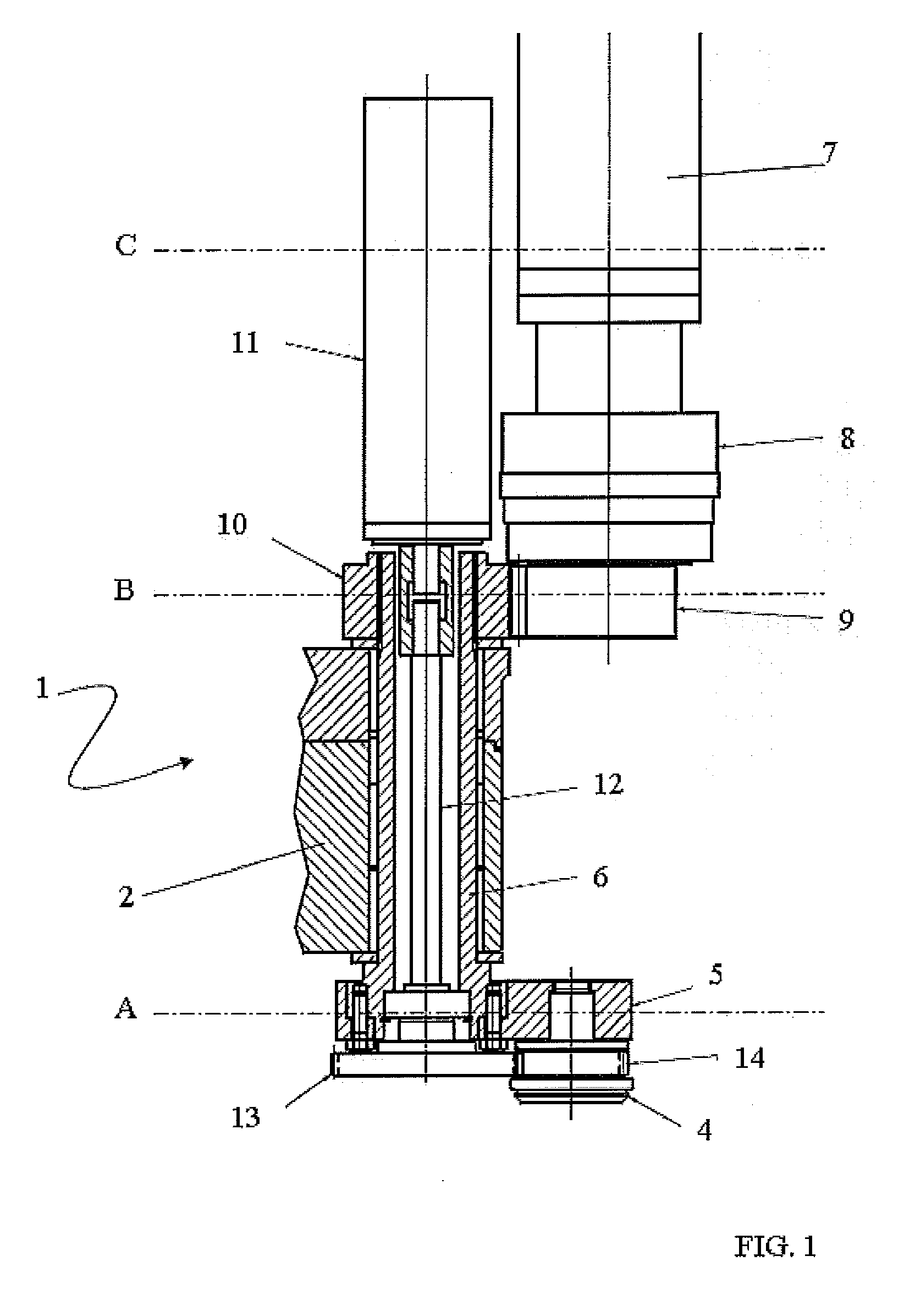

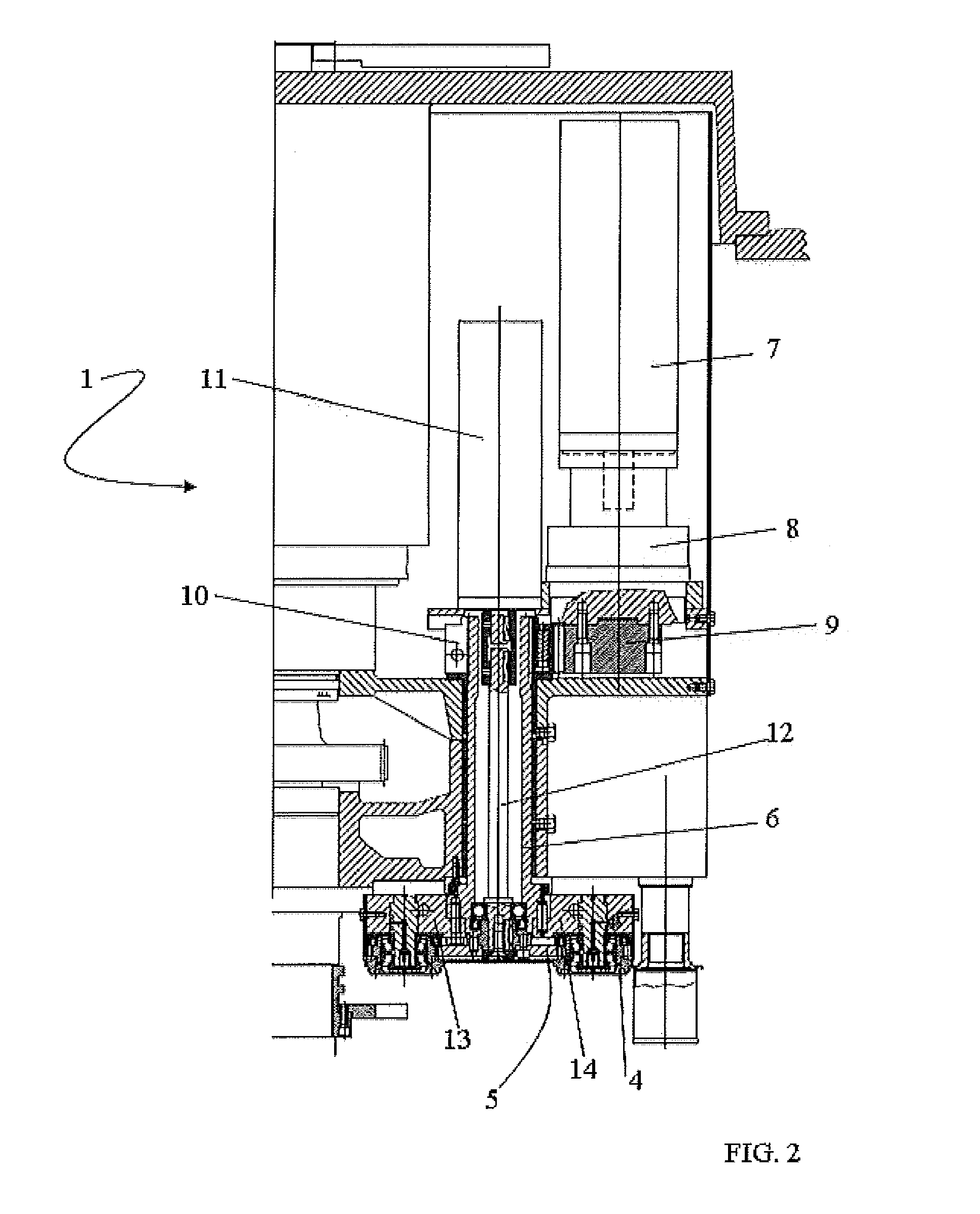

[0032]In the figures, the reference 1 indicates a seamer according to the present invention. The seamer 1 is a rotary seamer, comprising a carrousel 2 rotating around its own longitudinal axis.

[0033]To the carrousel 2 is associated a plurality of seaming stations 3; in the illustrated example (FIGS. 3-5), the seamer 1 comprises four seaming stations 3. The seaming stations 3 are substantially identical to each other and preferably positioned symmetrically on the carrousel.

[0034]FIGS. 1 and 2 show in particular one of said seaming stations 3.

[0035]The seaming station comprises a roller 4 mounted on a lever 5 integral with a rod-like element 6 rotatably coupled to the carrousel 2.

[0036]The roller 4 constitutes a seaming tool that, operatively, comes in contact with an object to be seamed positioned on a mandrel or another rotary element (not shown in the figures because it is known) associated with the carrousel 2.

[0037]The roller 4 is movable from an operative position, in which it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com