Method and apparatus for changing the trajectory of a projectile

a projectile and trajectory technology, applied in the field of defensive shielding, can solve the problems of increasing the weight of the vehicle, reducing the mobility of the vehicle, and changing the design of the armor, and achieve the effect of reducing the effectiveness of impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

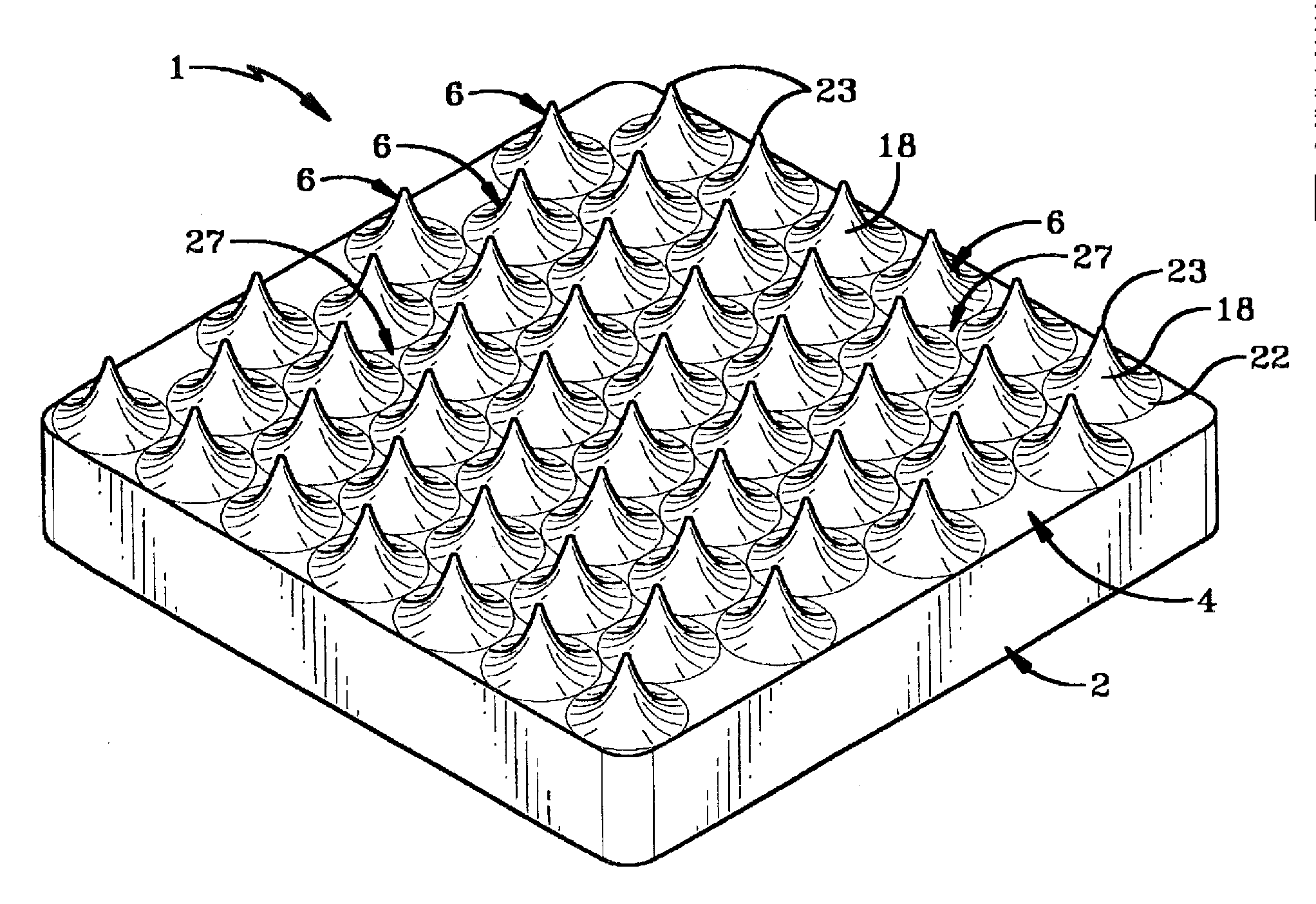

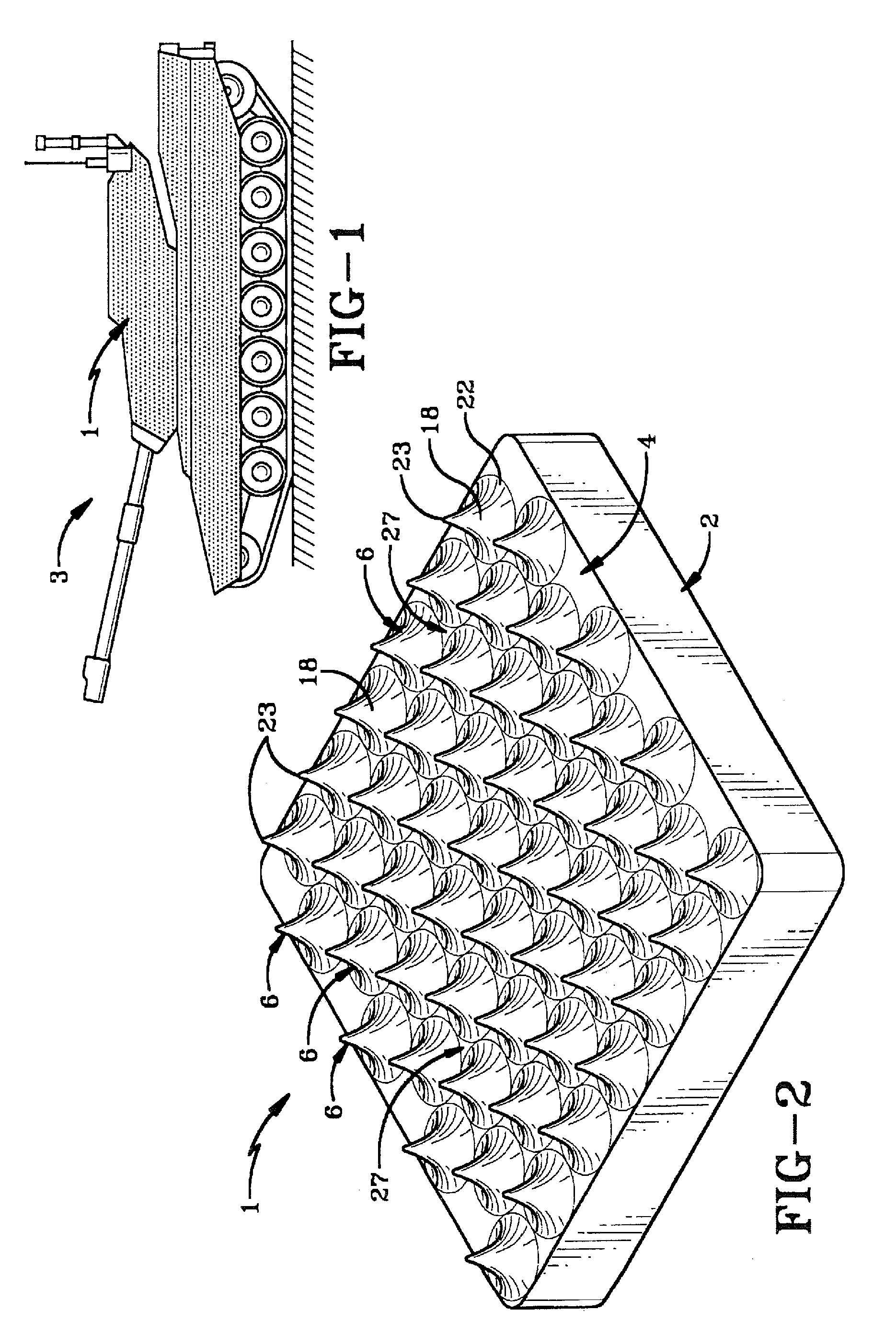

first embodiment

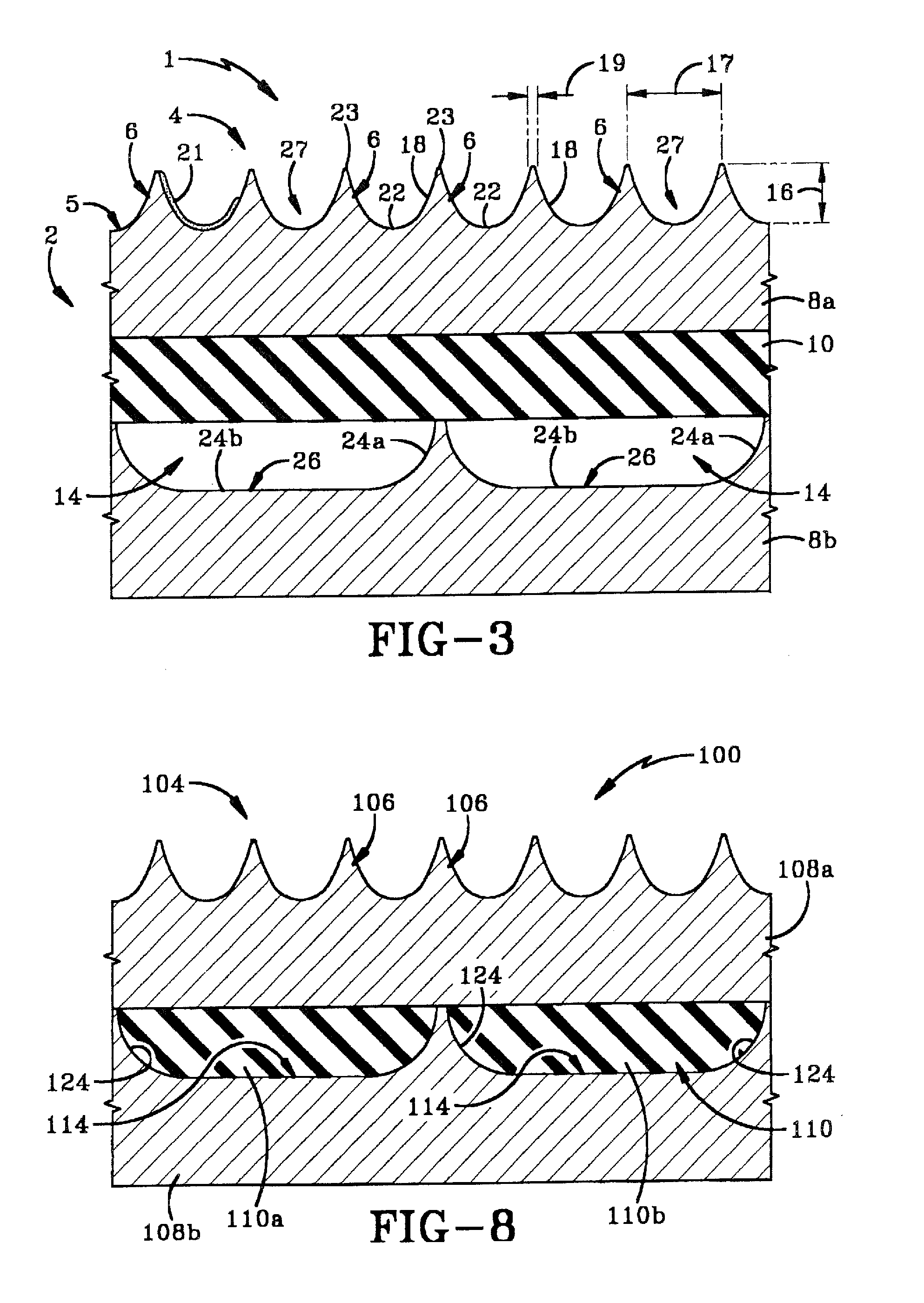

[0034]Referring to FIG. 3, there is shown armor 1 wherein the armor base 2 is a composite armor being made from at least two materials, such as steel and ceramic. The steel and ceramic are disposed in layers, such as in an exterior layer 8a, a middle layer 10 and an interior layer 8b. So, for example, in FIG. 3, exterior and interior layers 8a, 8b may be steel layers and middle layer 10 may be a ceramic layer. Layers 8a, 8b, and 10 are secured together in any manner known in the art. It will be understood that a plurality of layers of each of the two materials may be integrated into armor base 2. It will further be understood that additional layers of other materials, such as rubber or polymers, may also be incorporated therein.

[0035]Armor base 2 preferably further defines one or more caverns 14 spaced a distance inwardly from armor face 4. Caverns 14 are shown defined in interior layer 8b, but may alternatively or additionally be formed in any of the other layers. Each cavern 14 co...

second embodiment

[0044]protrusion armor system is shown in FIG. 8 and generally indicated at 100. Armor 100 comprises a first layer 108a and a second layer 108b made from the same material. A second material 110 is provided in discrete pockets 110a and 110b within material 108. Armor 100 includes protrusions 106 that provide a similar type of protection as armor 1, but in addition to this pockets 110a and 110b include arcuate interior sidewalls 124. These arcuate sidewalls 124 aid in deflecting projectiles 30 in much the same way as the sidewalls 118 of protrusions 106, except that a projectile would be forced to travel through the material within pocket 110a and 110b whereby the kinetic energy of the projectile will therefore be greatly dissipated.

[0045]Operationally, the second embodiment of the present invention deflects projectiles in the same method as the first embodiment. The second embodiment of protrusion armor system 110 deflects projectiles using a plurality of a protrusion 106 on an armo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com