Paint can liner

a paint can and liner technology, applied in the field of paint can liner, can solve the problems of saving painter time and cost, and achieve the effect of eliminating the time spent in extra cleanup, saving painter time and cost, and being convenient to us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

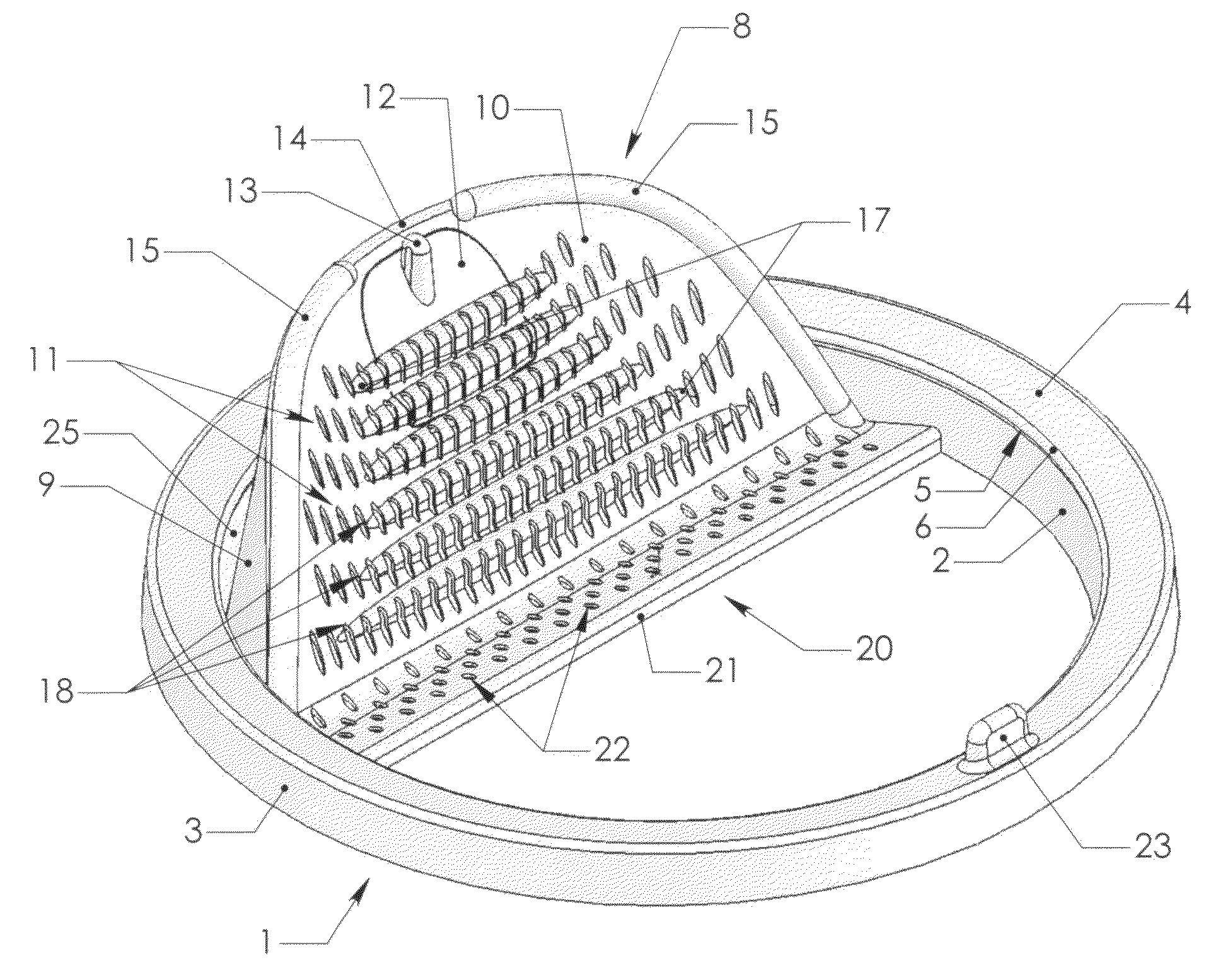

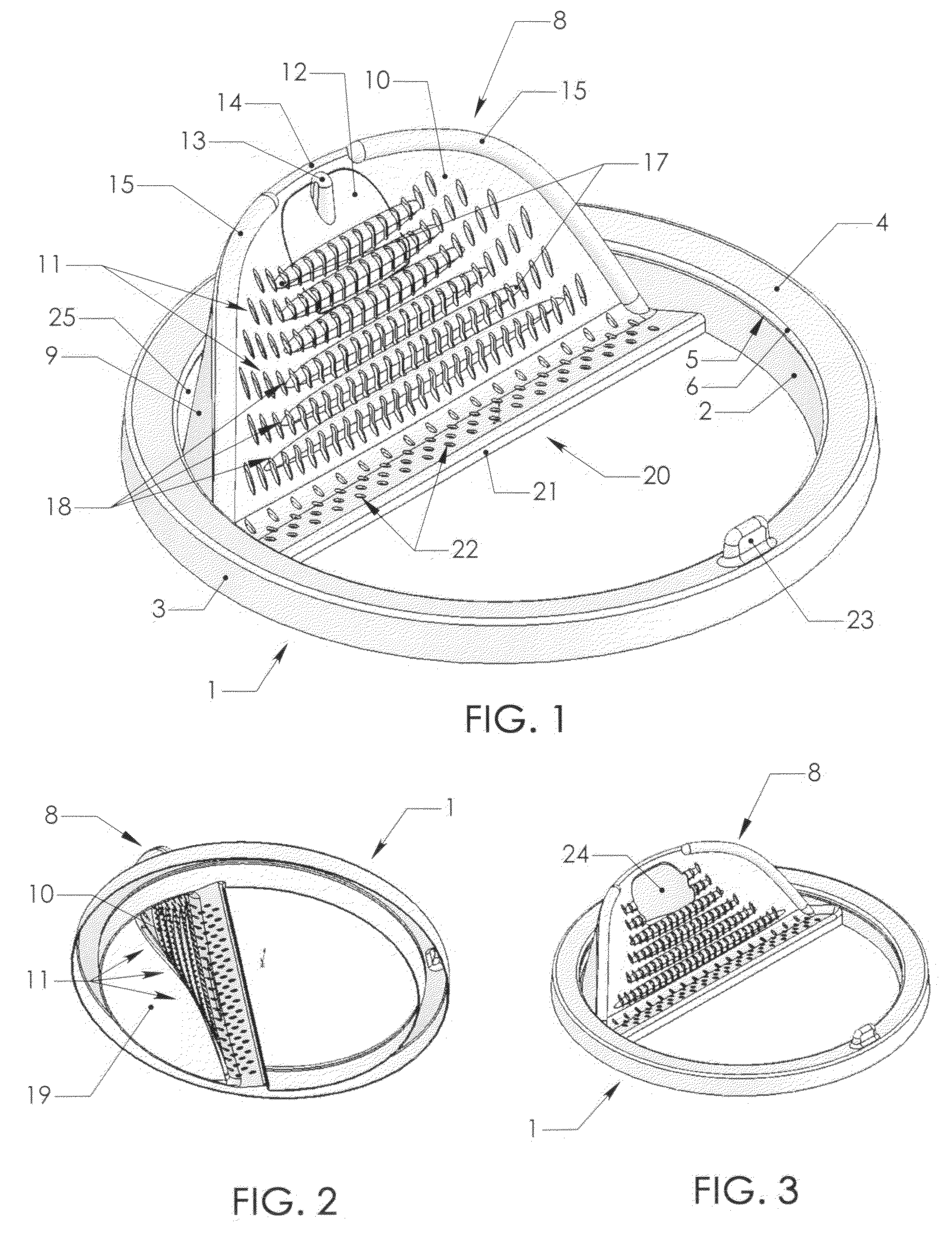

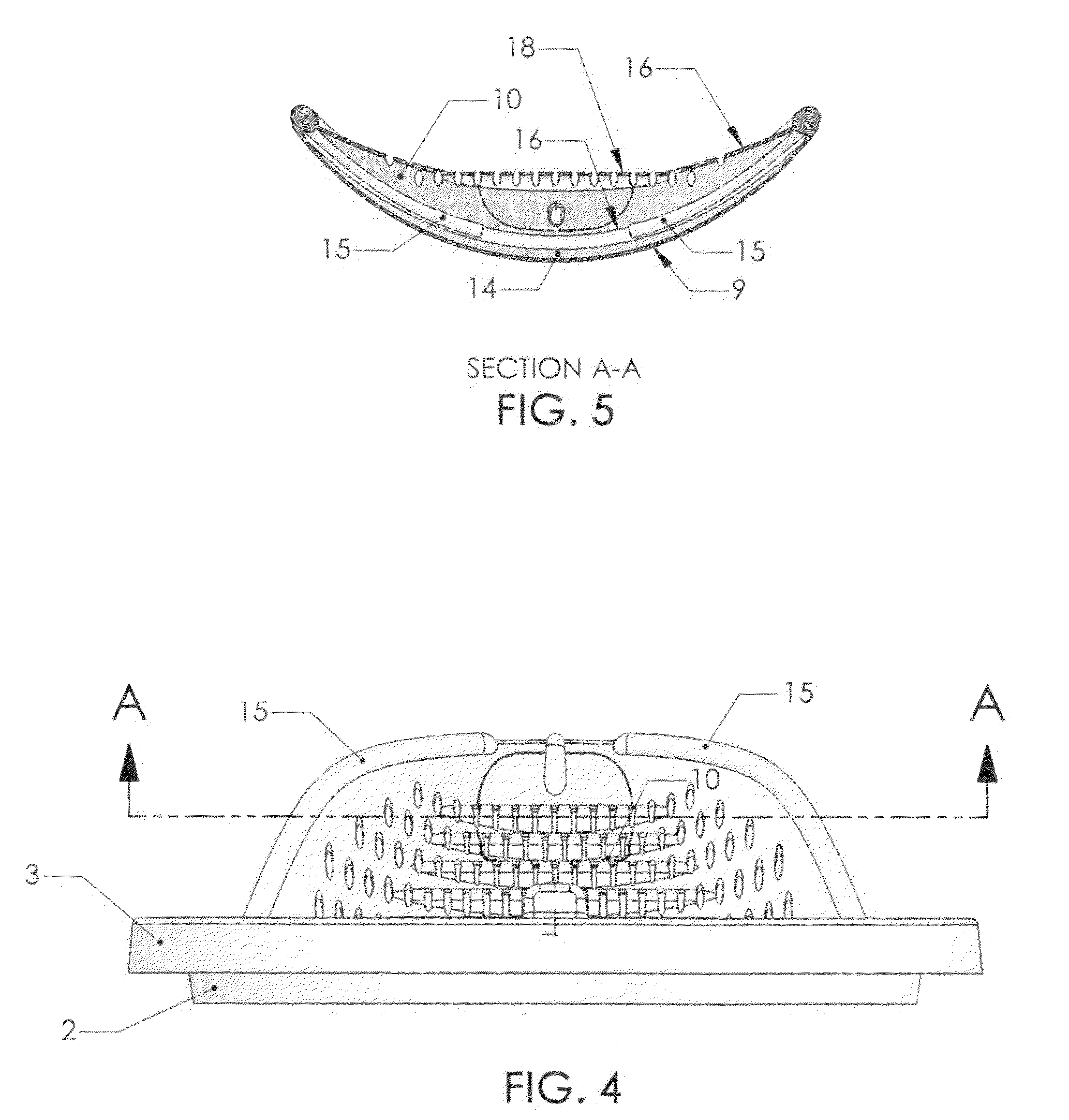

[0026]Depicted in FIG. 1 which is a fundamental embodiment common to all variations of the present disclosure, is the annular mounting ring 1 that affixes to the top of an open cylindrical paint can (not shown) either of plastic or metal. Since the sealing configuration for metal cans differs from those made of plastic, the mounting configuration likewise differs. For a Paint Can Liner specific to metal paint cans, the mounting ring 1 includes an annular top-wall 4 extending down into interior 2 and exterior 3 side-walls. An inwardly facing annular mounting groove 6 formed within the interior side-wall 2 permits the mounting ring 1 to become locked as well as sealed to the paint can.

[0027]The mounting mechanism is more clearly visualized by referring to the cross-sectional view, FIG. 7, which details the mounting portion applied to a metal paint can 30. In its preferred configuration, the mounting groove 6 is bounded by an annular mounting ridge 5 directly below and by the top-wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com