Active Rotor Alignment Control System And Method

a control system and rotor technology, applied in the direction of machines/engines, mechanical equipment, engine starters, etc., can solve the problems of limiting the amount of minimum designed clearance that can be achieved, unable to account for eccentricities that either develop or are inherent between the rotor and the shroud, and damage to the blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]Reference is now made to particular embodiments of the invention, one or more examples of which are illustrated in the drawings. Each embodiment is presented by way of explanation of aspects of the invention, and should not be taken as a limitation of the invention. For example, features illustrated or described with respect to one embodiment may be used with another embodiment to yield still further embodiment. It is intended that the present invention include these and other modifications or variations made to the embodiments described herein.

[0021]Aspects of the present invention will be described herein with respect to a gas turbine configuration. However, it should be appreciated that the present invention is not limited to gas turbines, and is applicable to rotating machines in general wherein it is desired to detect and compensate for eccentricities between a rotor and a surrounding casing structure.

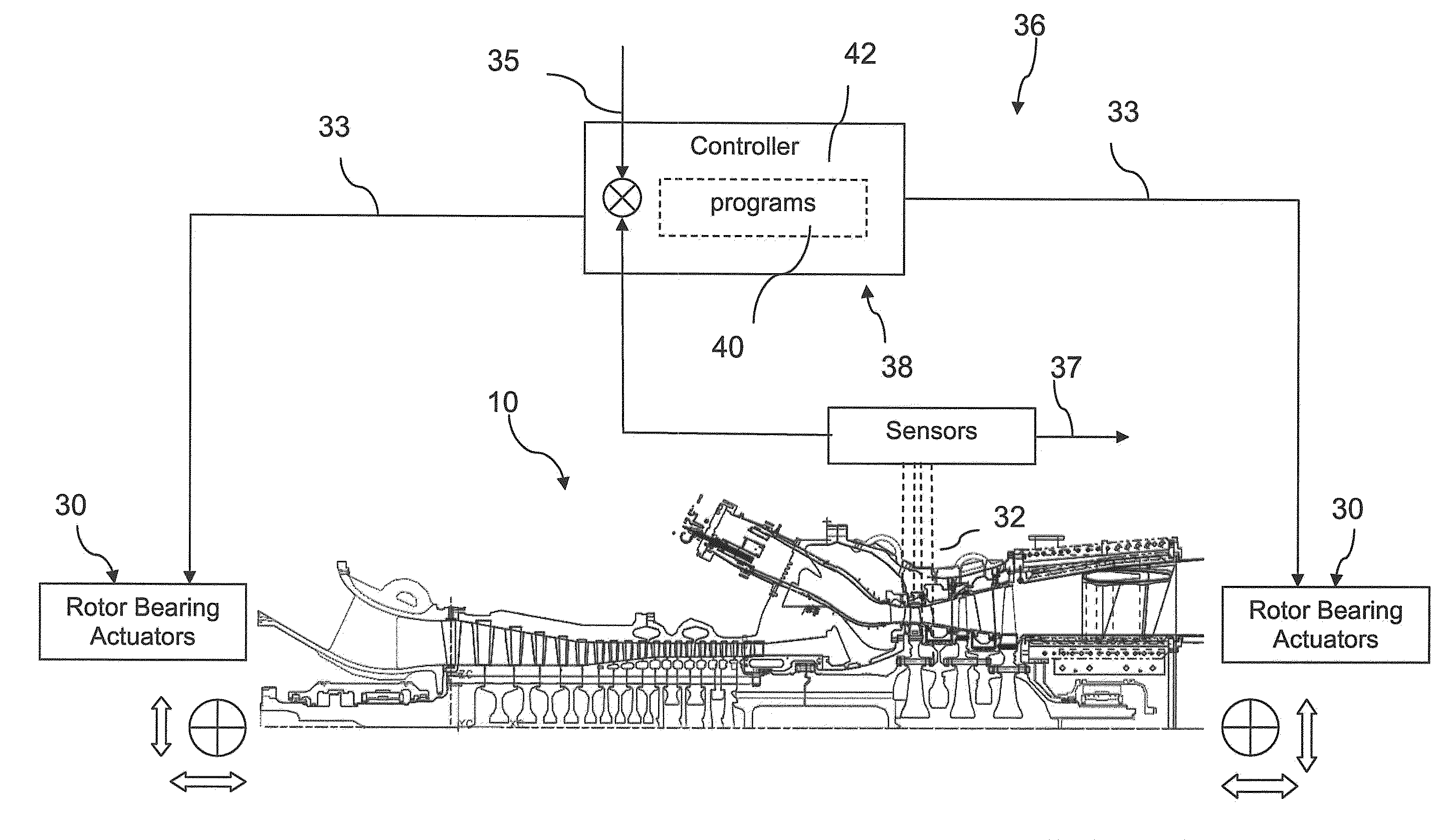

[0022]FIG. 1 illustrates an exemplary embodiment of a conventional rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com