Wellbore Shut Off Valve with Hydraulic Actuator System

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

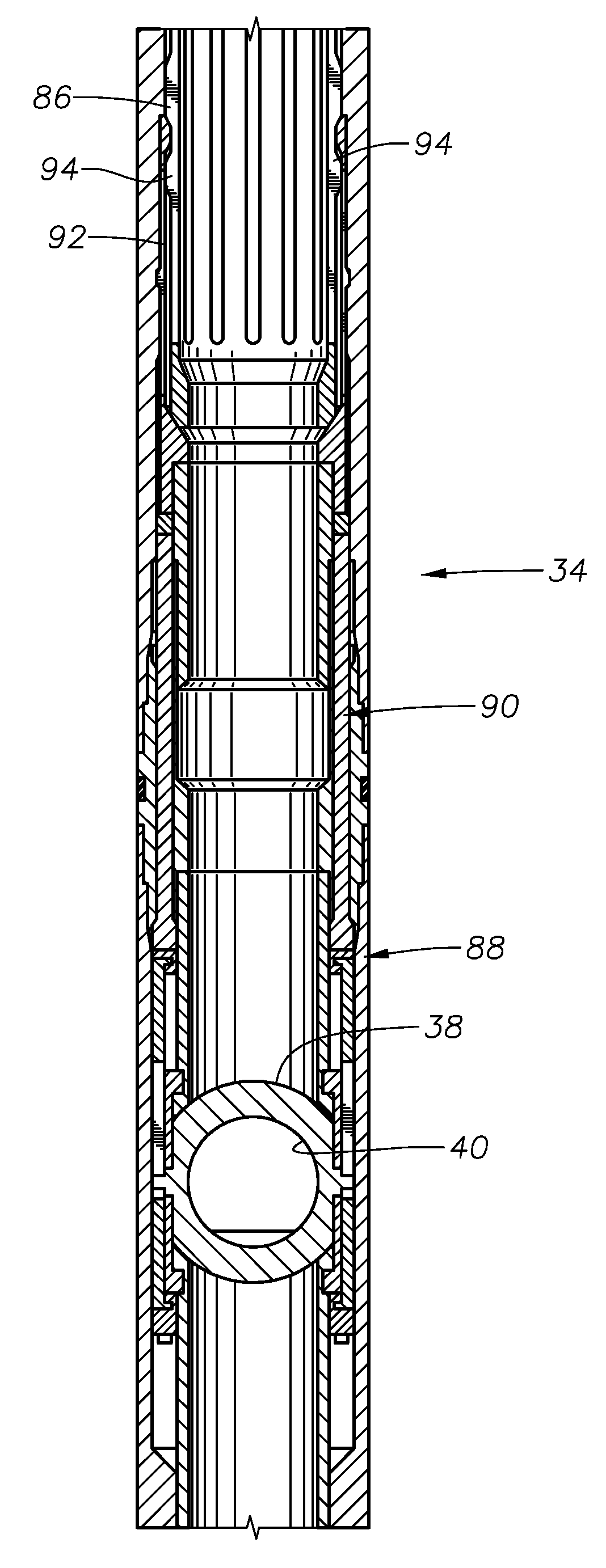

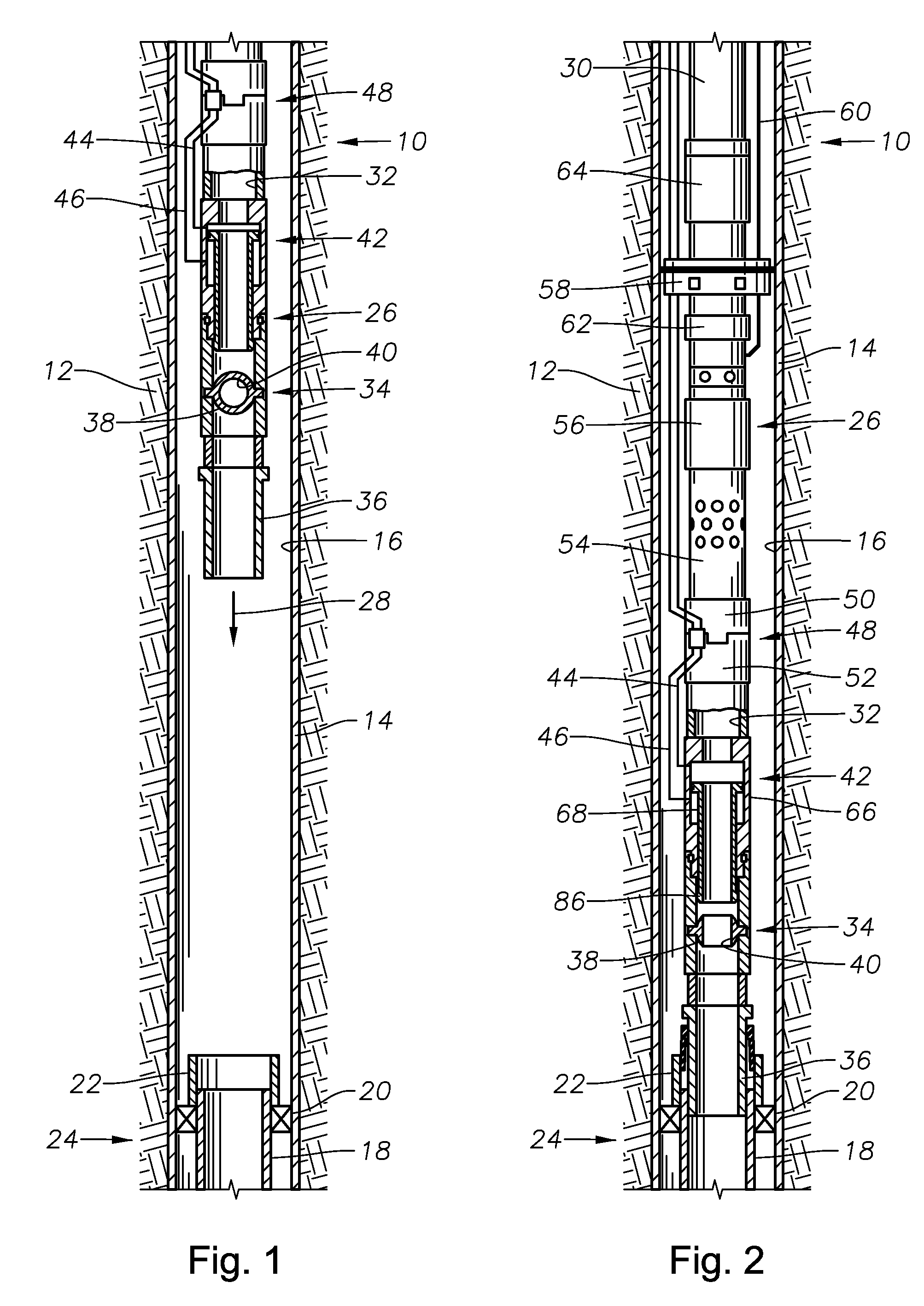

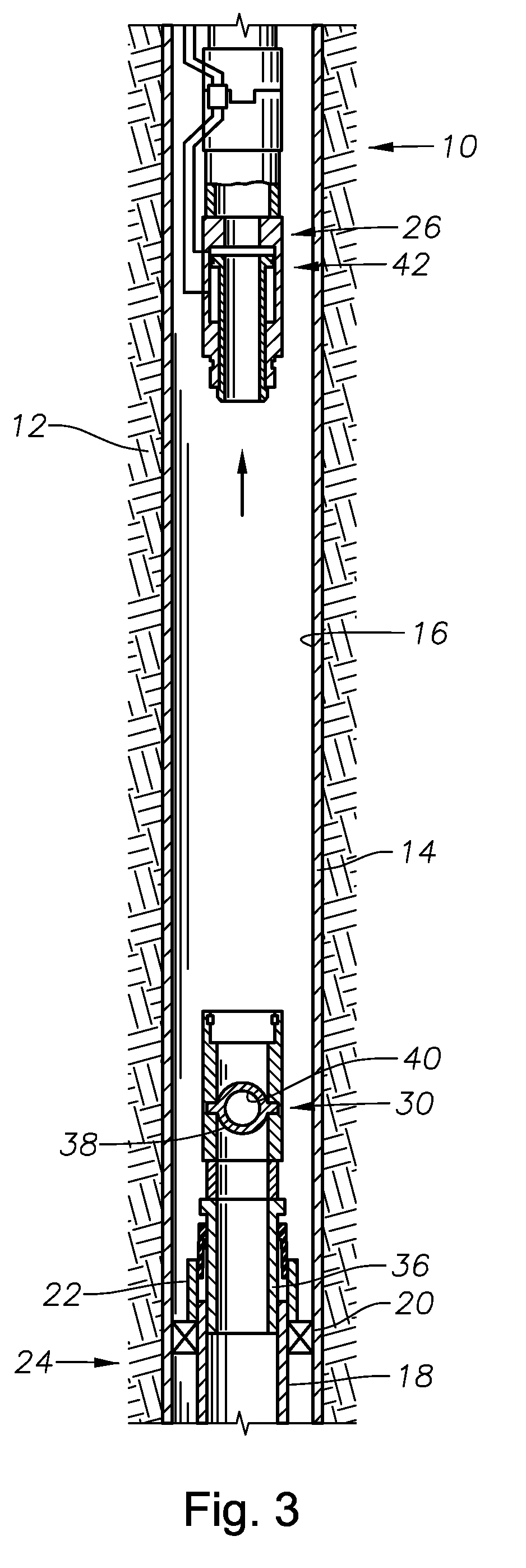

[0019]Referring first to FIGS. 1 and 2, there is depicted an exemplary wellbore 10 which has been drilled into the earth 12 and is lined with casing 14 which will extend upwardly toward the surface of the wellbore 10. The casing 14 defines a central flowbore 16. The wellbore 10 contains an exemplary production string assembly which will be used to illustrate the invention. It is noted that, in this example, the section of the wellbore 10 which is depicted is representative of an upper pump-assisted completion within the wellbore 10 and that one or more additional completions may be located below the wellbore portion that is shown. As a result, a lower portion of production tubing string 18 is shown extending downwardly within the flowbore 16 from lower packer 20. A landing anchor 22 extends axially upwardly from the packer 20. Collectively, the lower production tubing string portion 18 and elements suspended below it, as well as the packer 20 and anchor 22 may be thought of as a low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com