Method of excavation of oil and gas-producting wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

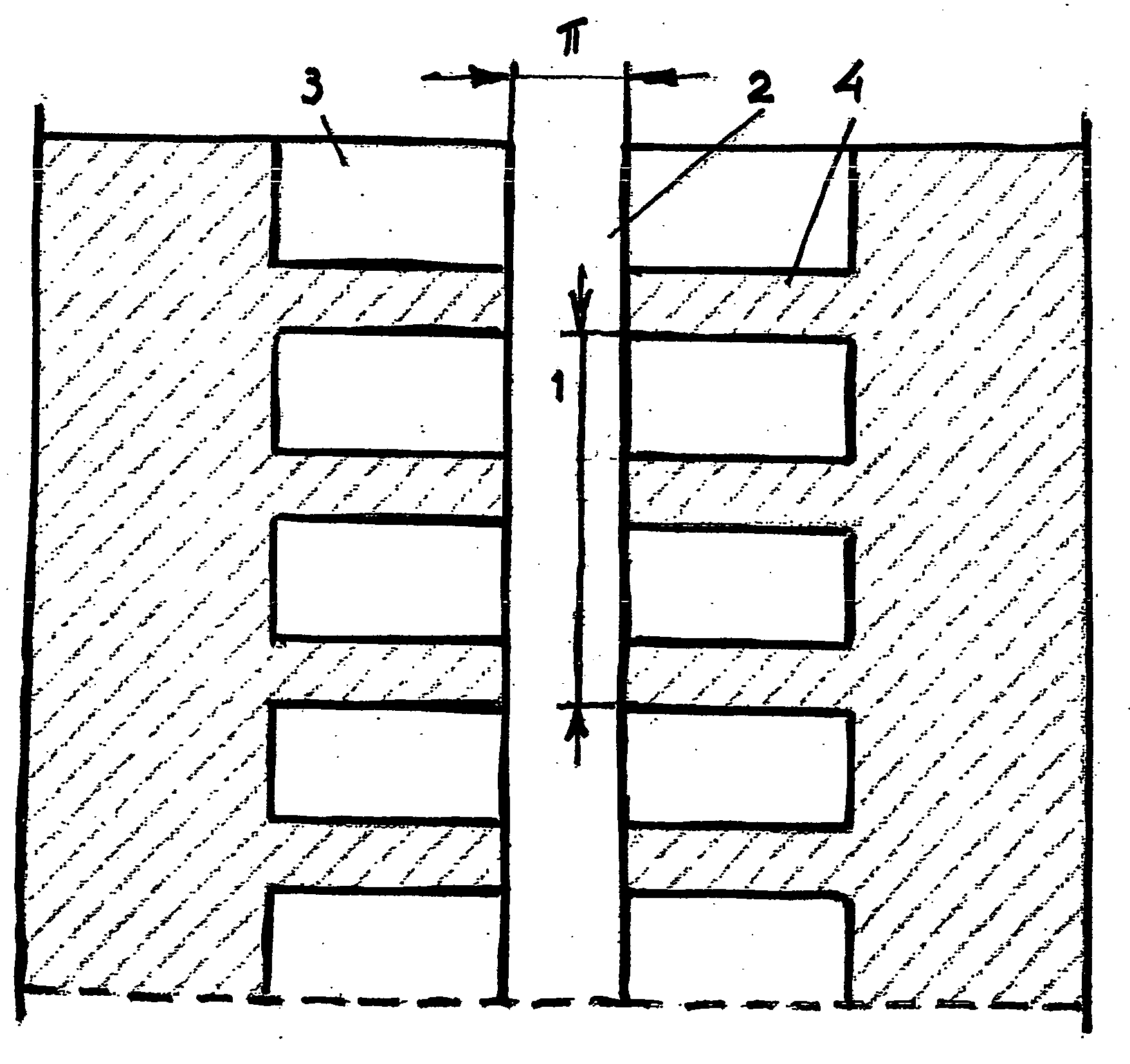

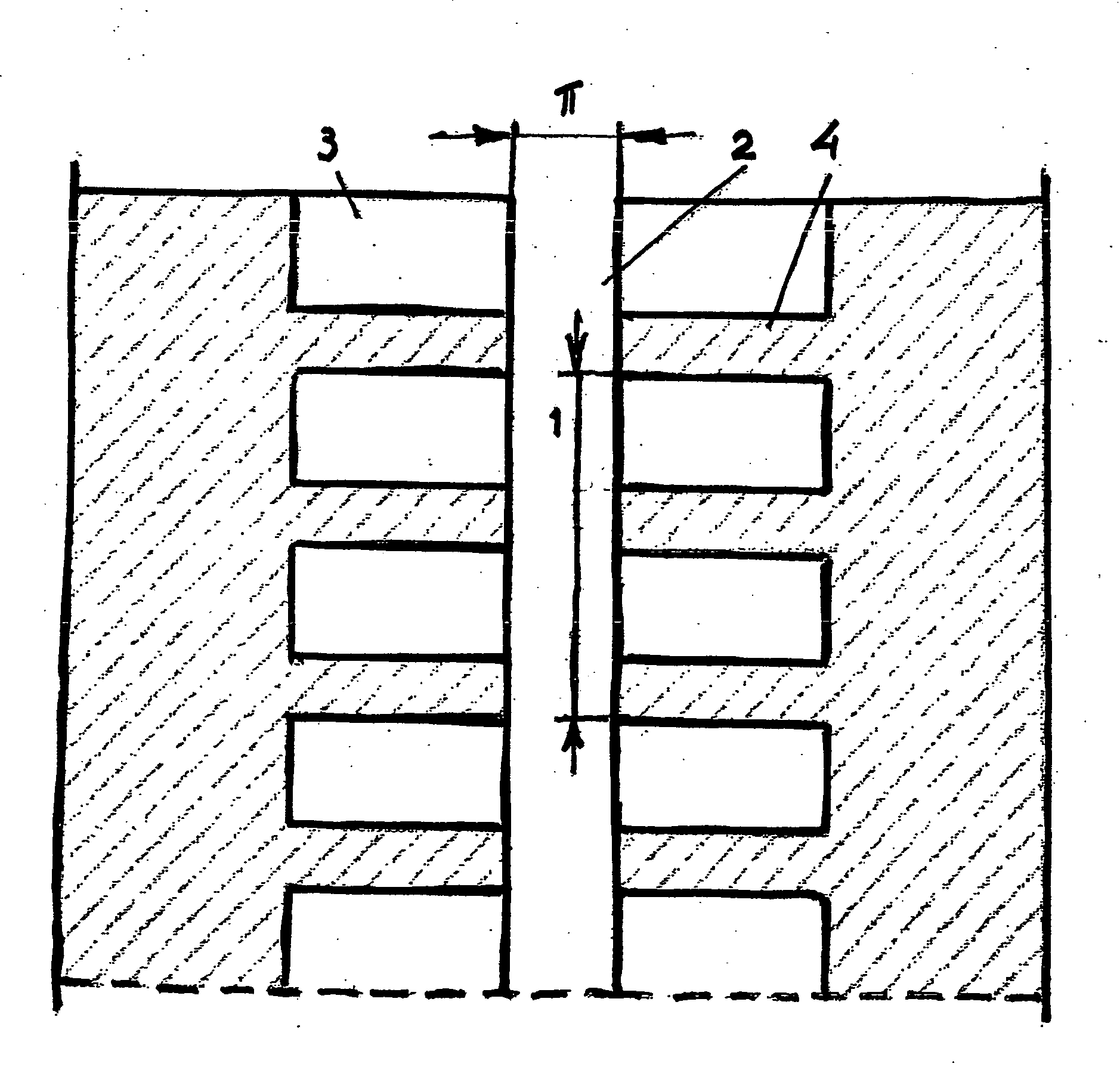

[0010]The method in accordance with the present invention includes cutting of two slots in one plane so as to form a partition of rock between them and so that stresses from surfaces of slots are redistributed onto the partition and create in it additional pressure; and selecting widths of the slots and the partition such that the partition becomes so stressed that it self-destructs, and as a result a single slot is formed with a length which is equal to lengths of both initial slots and the partition.

[0011]In accordance with the invention values have been determined of sizes of the slots and distances between them for self-destruction of the partitions. The partition is in extreme stressed condition with the size:

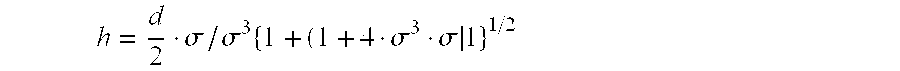

h=½·σ / σ3{1+}1+4|σ3 / σ1}1 / 2

The parameters in this formula take into consideration sizes of contour slot, strength characteristic of the layer (σ3) and a value of stresses taken from the slots (σ). The formula is obtained as follows.

[0012]Extreme load Pst on the partition is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com