Image forming apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

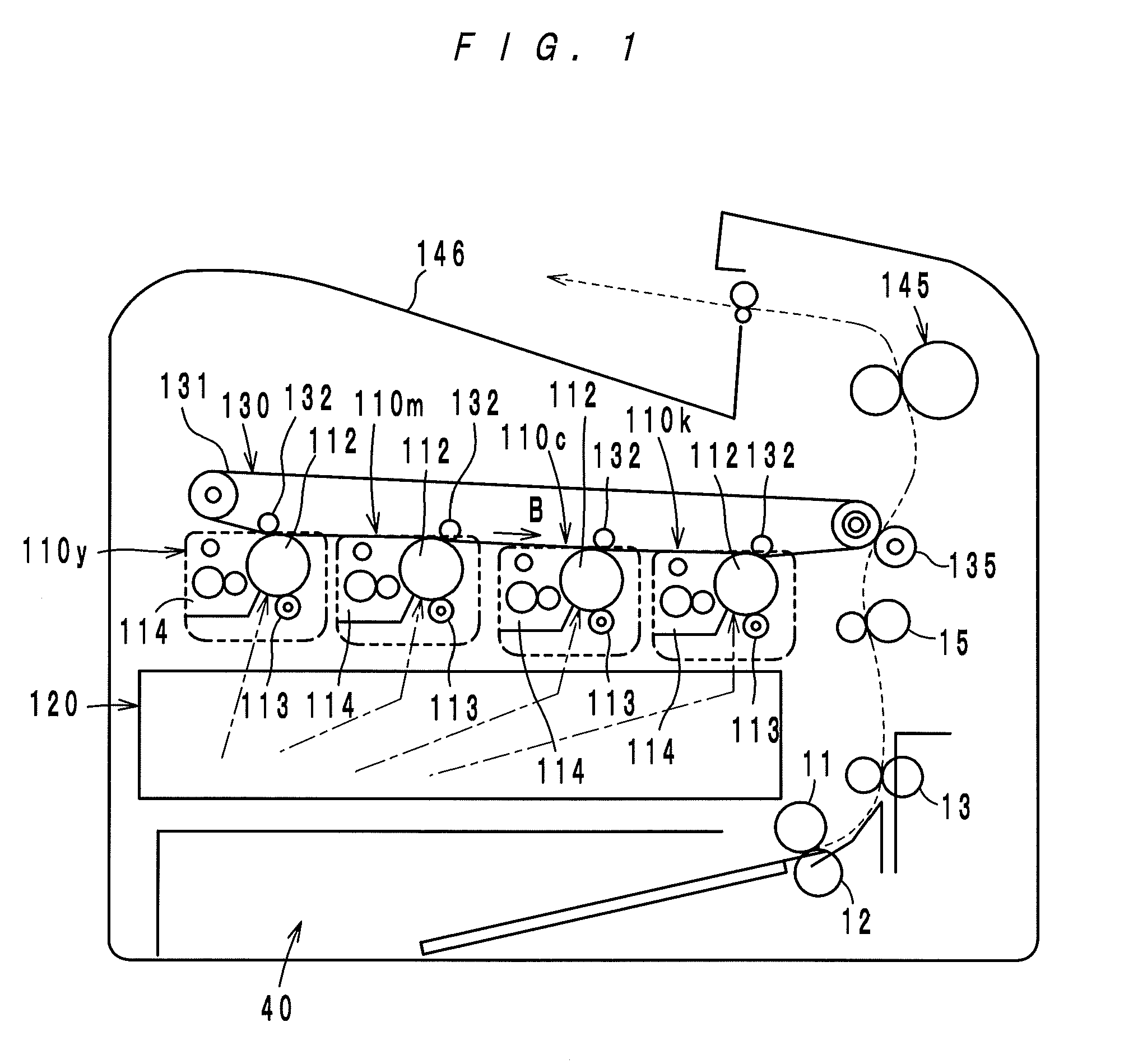

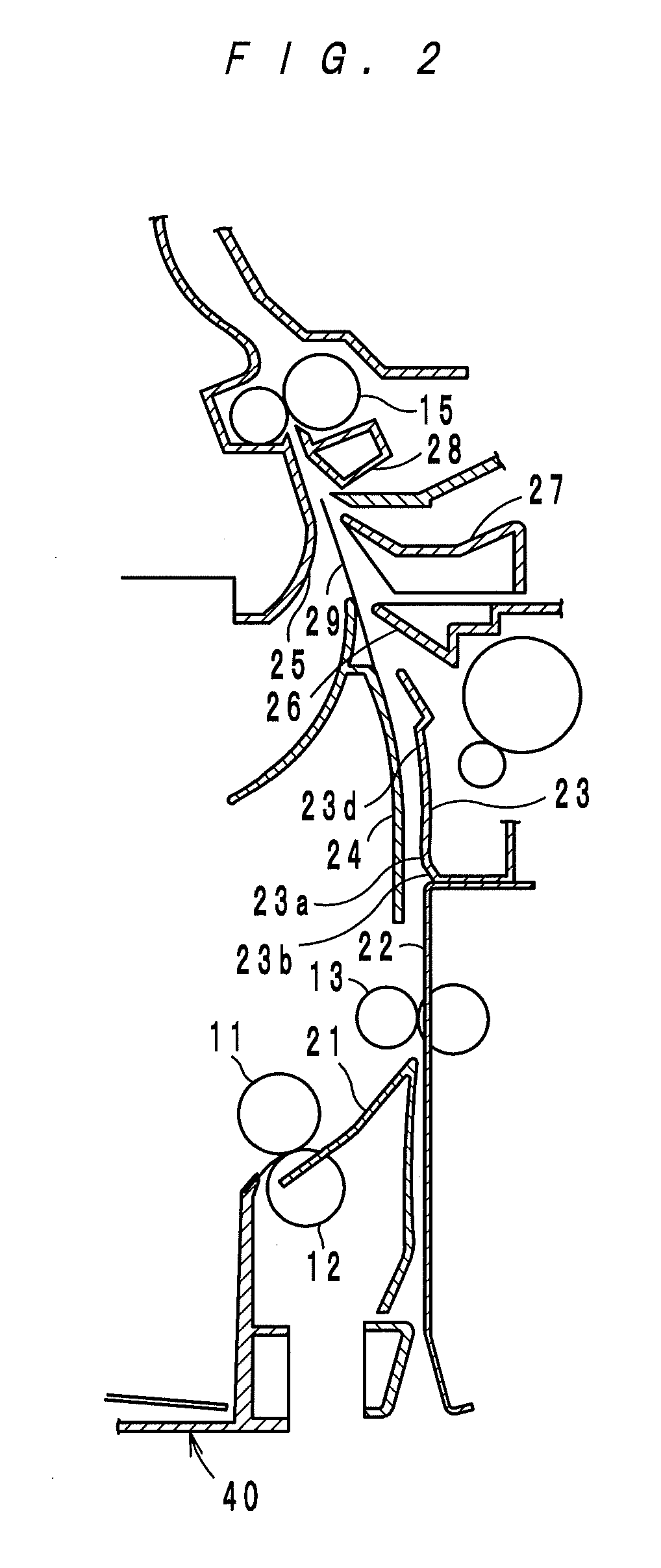

[0018]An image forming apparatus according to an embodiment of the present invention is hereinafter described with reference to the accompanying drawings. In the drawings, the same members and parts are provided with the same reference symbols, and repetitions of the same descriptions are omitted.

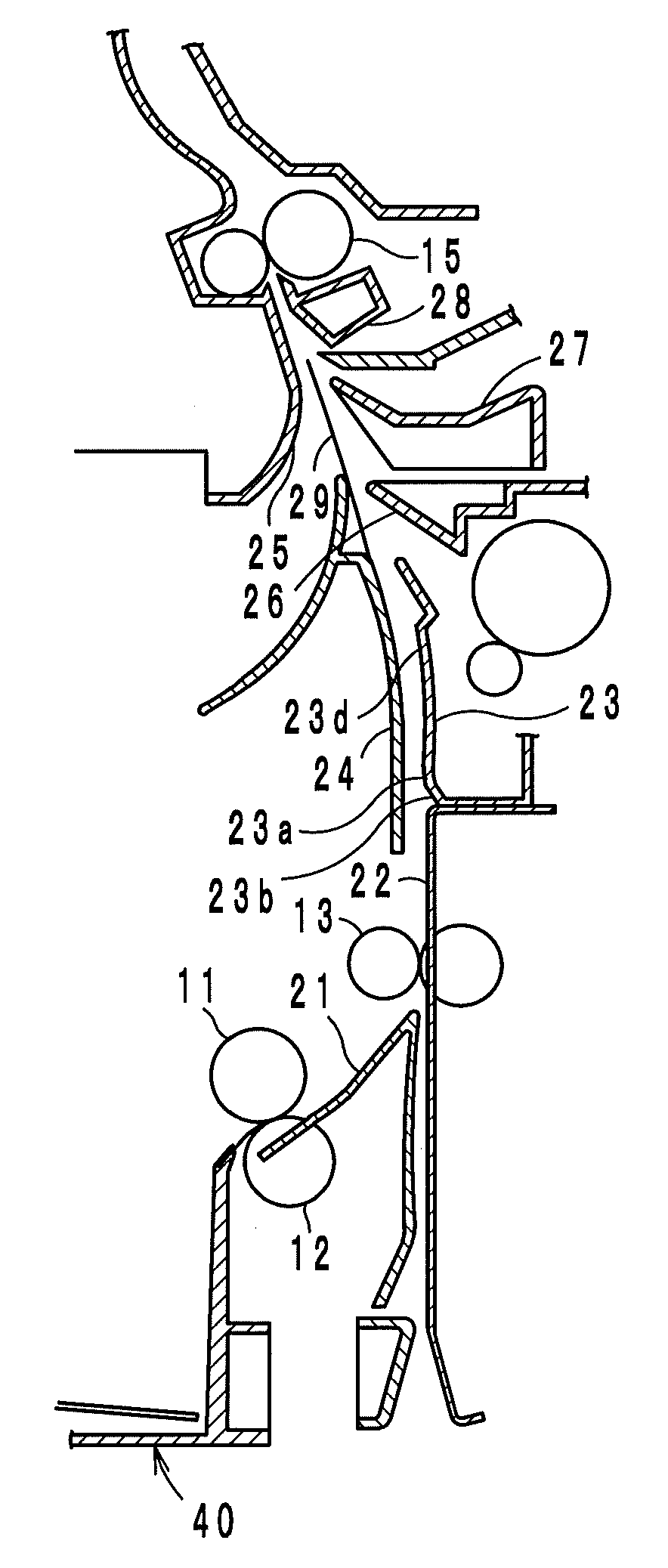

[0019]An image forming apparatus according to an embodiment of the present invention is described with reference to FIG. 1. The image forming apparatus is a tandem type color printer. The printer mainly comprises process units 110 (110y, 110m, 110c and 110k) for forming toner images of yellow (Y), magenta (M), cyan (C) and black (K) respectively, a laser scanning unit 120 and an intermediate transfer unit 130.

[0020]Each of the process units 110 comprises, in a housing shown by the dotted line in FIG. 1, a photosensitive drum 112, a charging roller 113, a developing device 114, a residual toner / charge cleaner, etc., and is capable of sliding in a direction perpendicular to the paper surface ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap