Rolling ball style cosmetic container structure

a container structure and cosmetic technology, applied in packaging foodstuffs, transportation and packaging, packaged goods types, etc., can solve the problems of inconvenient handling of liquid leakage, easy liquid leakage, and short function of conventional rolling ball cosmetic containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

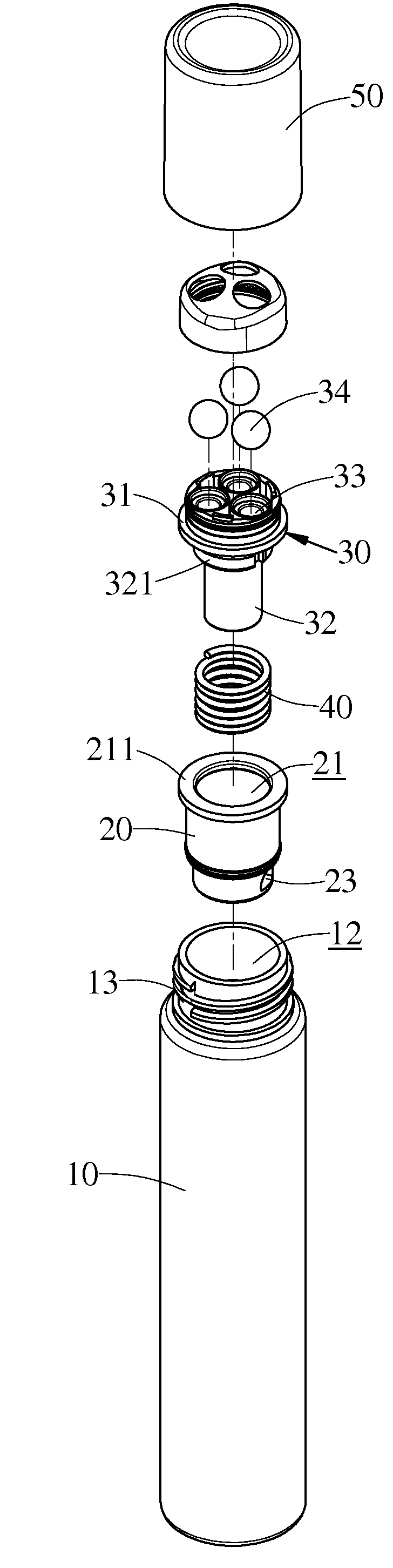

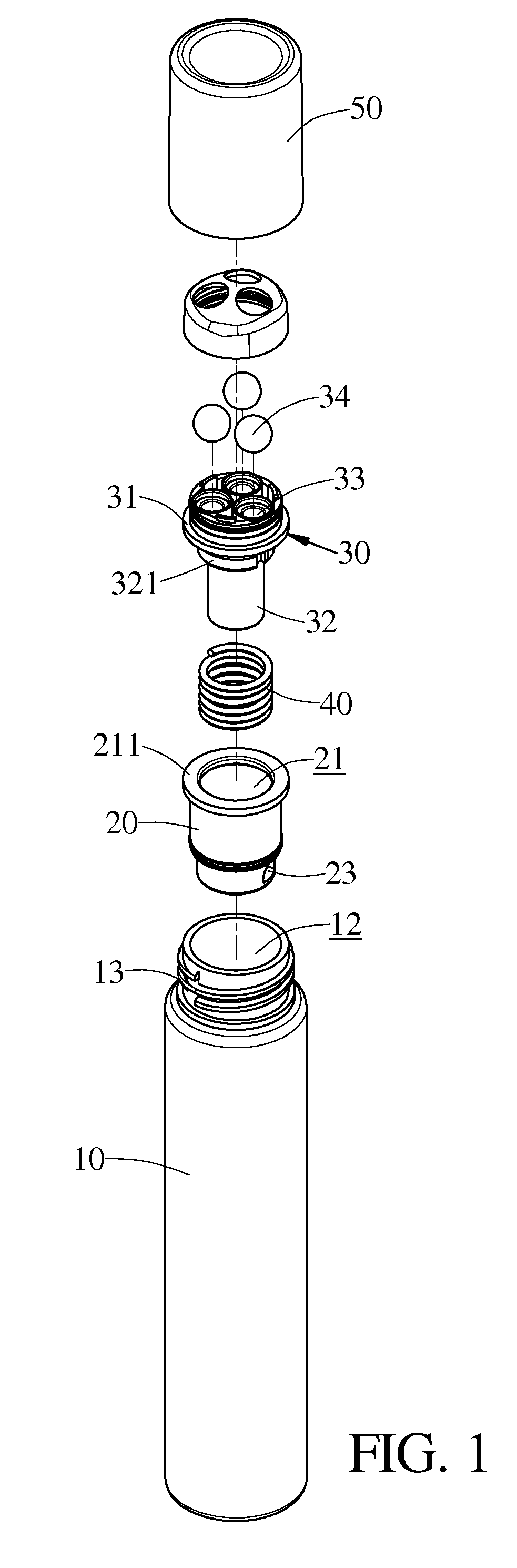

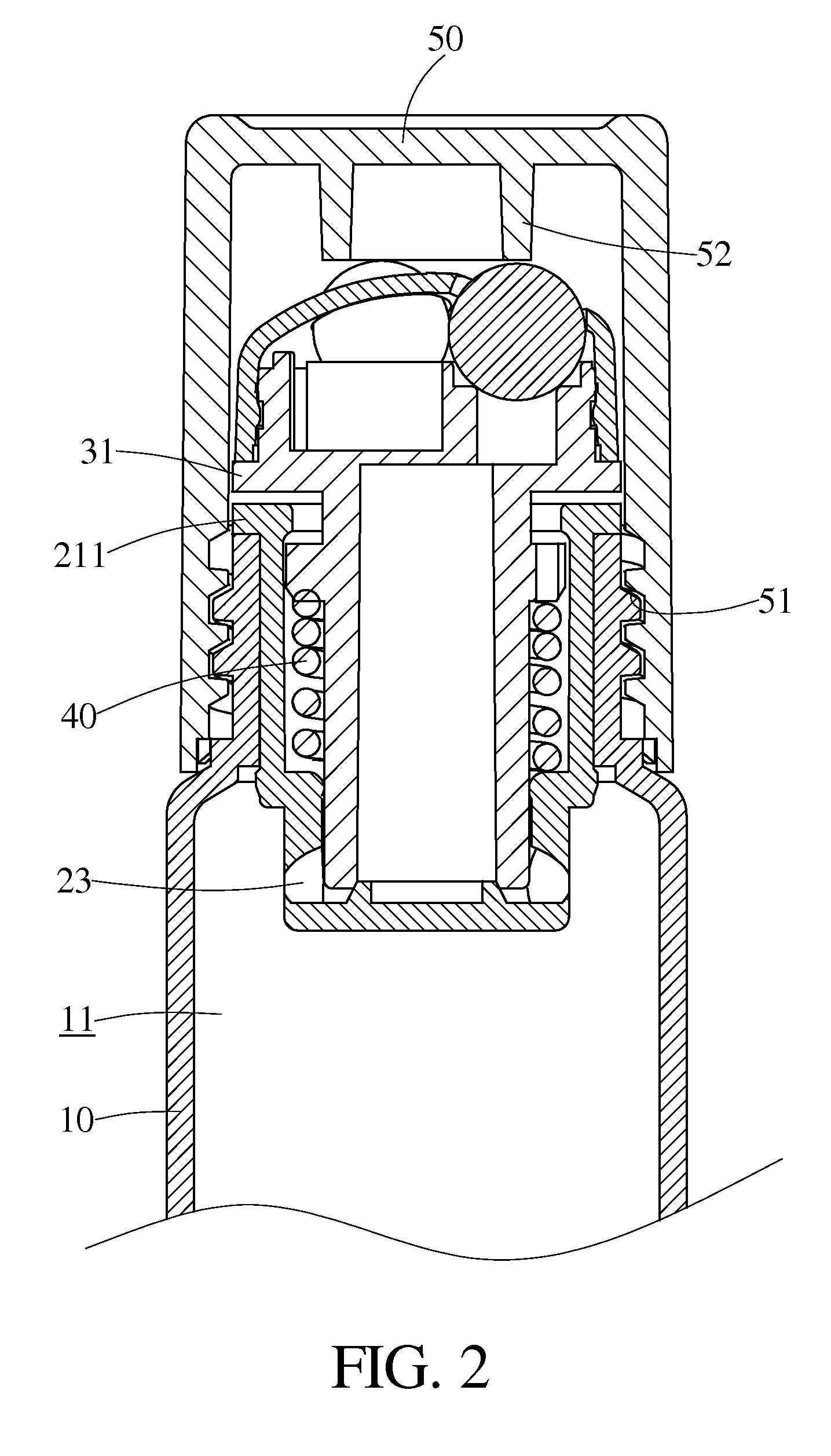

[0023]Referring to FIGS. 1 to 5, a rolling ball style cosmetic container structure includes a tube 10, an axle sleeve 20, a hollow piston rod 30, a resilient member 40 and an exterior cap 50. The tube 10 includes a containing space 11 for containing liquid, a opening 12 and a threaded part 13, the opening 12 arranged axially at one end. The threaded part 13 is mounted near the opening 12.

[0024]The axle sleeve 20 includes a holding space 21, an inner flange 212, an outer flange 211, a resistant holding surface 22 and a material discharge hole 23 extending between the holding space 21 and the containing space 11 of the tube 10. The resistant holding surface 22 is ladder-shaped. The resistant holding surface 22 formed inside the axle sleeve 20. The axle sleeve 20 is connected to the tube 10 by being sleeved at the inside of the opening 12.

[0025]The hollow piston rod 30 includes a flanged disk 31, an annular flange 321, a receiving space 33, a central bore 35 and a rod part 32. The rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com