Liquid container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

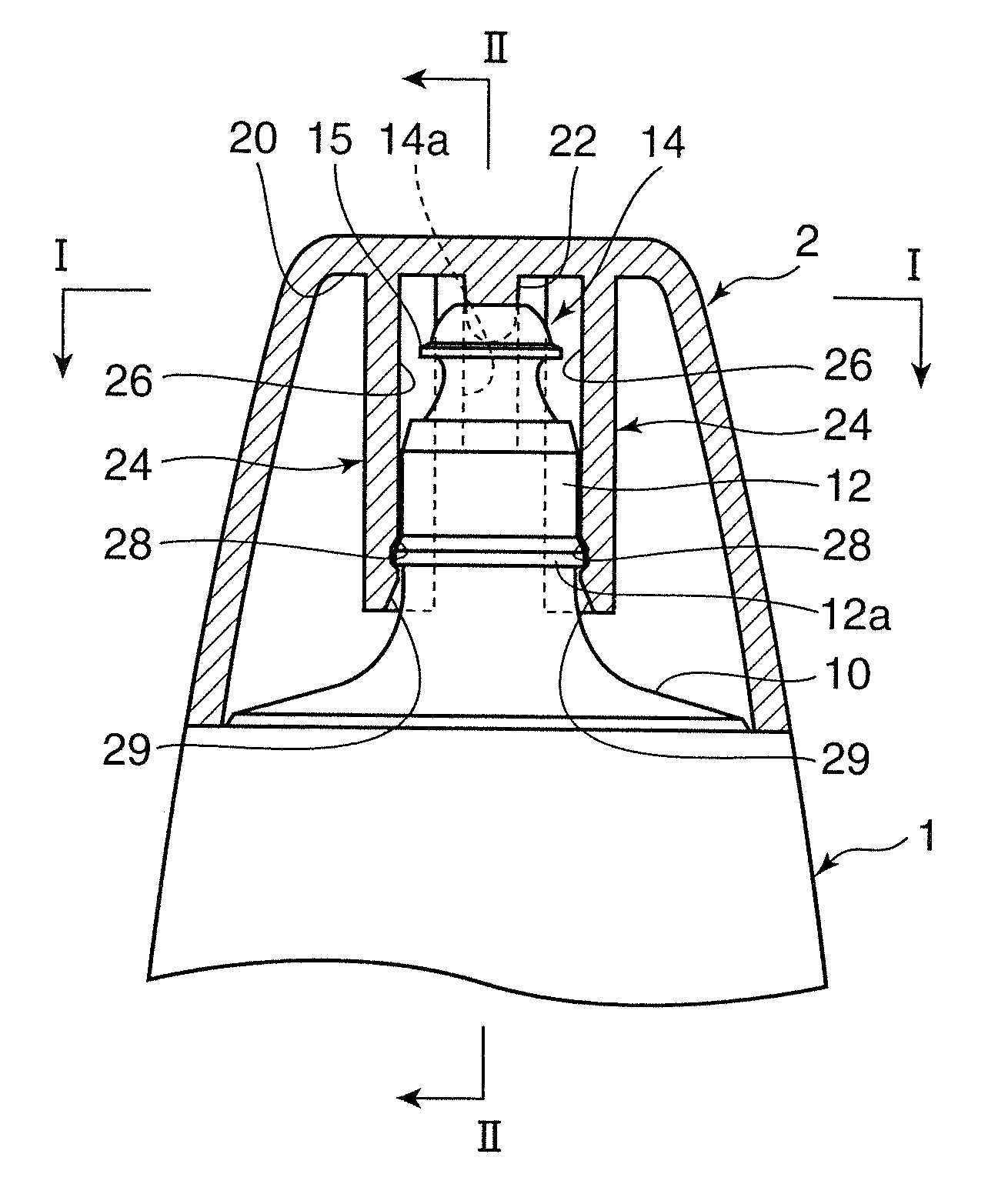

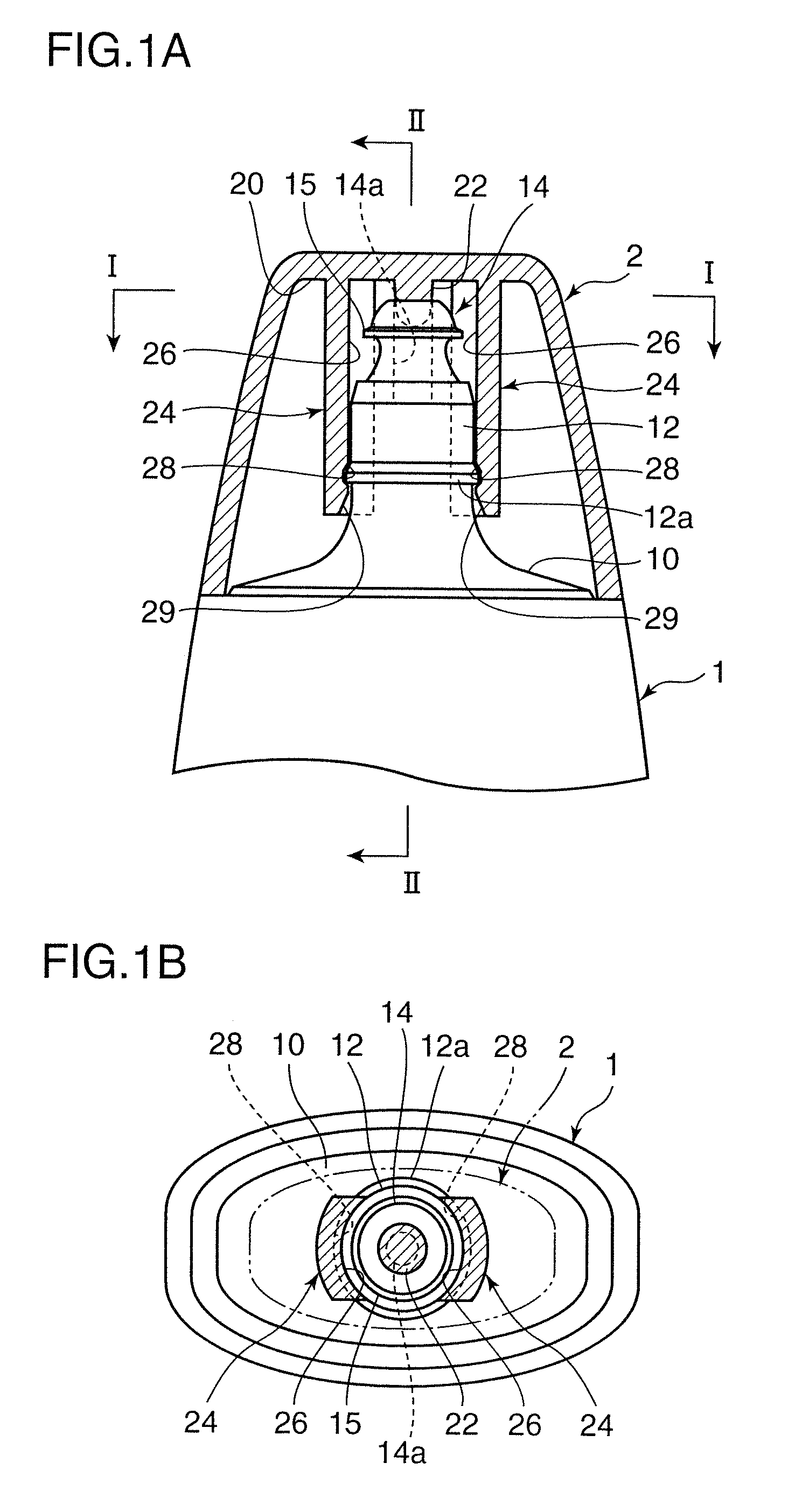

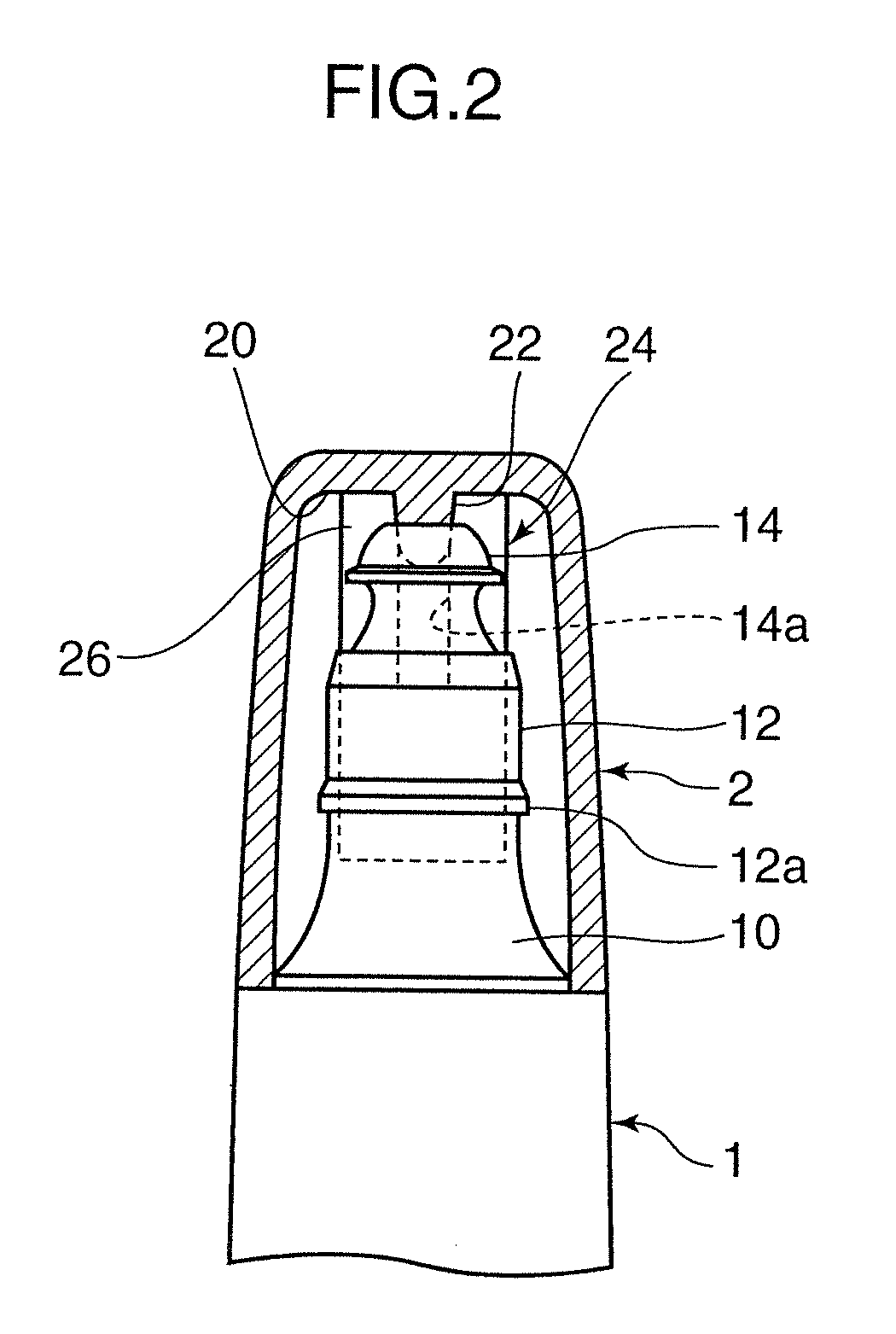

FIGS. 1 and 2 illustrate a substantial part of a liquid container according to the present invention.

The liquid container (hereinafter abbreviated as “container”) illustrated in FIGS. 1 and 2 is a so-called twist cap-type container. In this embodiment, this container is an eye drop container which comprises a container body 1 having a nozzle portion 14, and a cap 2 detachably attachable to the container body 1 to cover the nozzle portion 14, wherein it is designed, during instillation, to allow a medical solution contained in the container body 1 to be instilled from a tip end of the nozzle portion through an operation of gently pressing the container body 1 while orienting the tip end of the nozzle portion downwardly under a condition that the cap 2 is detached.

As shown in FIG. 1(b), the container body 1 is formed in a flat shape in a forward-rearward direction (upward-downward direction in FIG. 1(b)). The container body 1 is configured such that a circular tubular neck portion 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com