LED optical system

a technology of led optical system and led light, which is applied in the direction of semiconductor devices for light sources, fixed installations, lighting and heating apparatus, etc., can solve the problems of insufficient efficacy of devices, poor uniformity in all directions, and lambertian distribution, so as to achieve high uniformity, eliminate all waste of light, and gain efficiency through the light distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

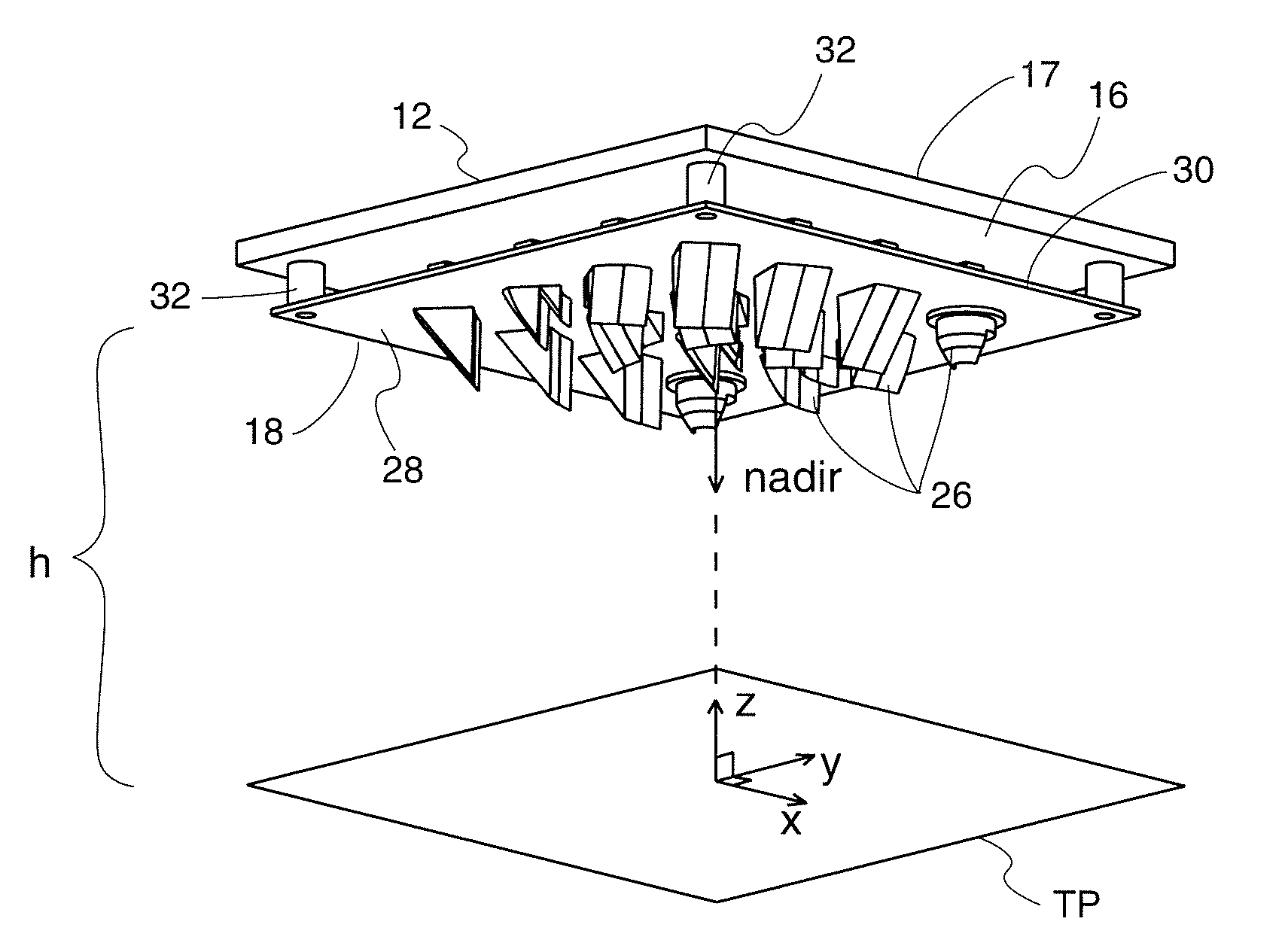

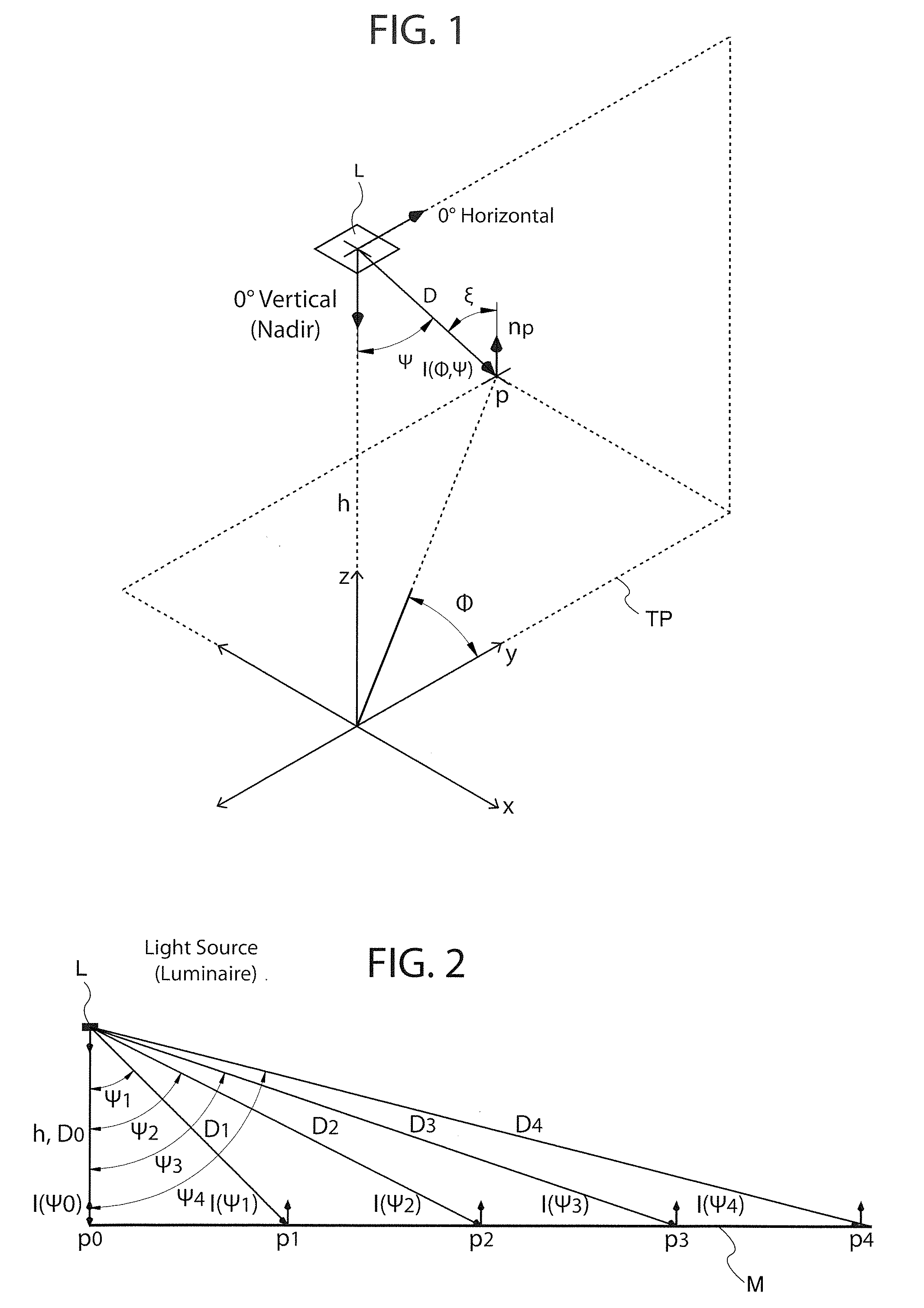

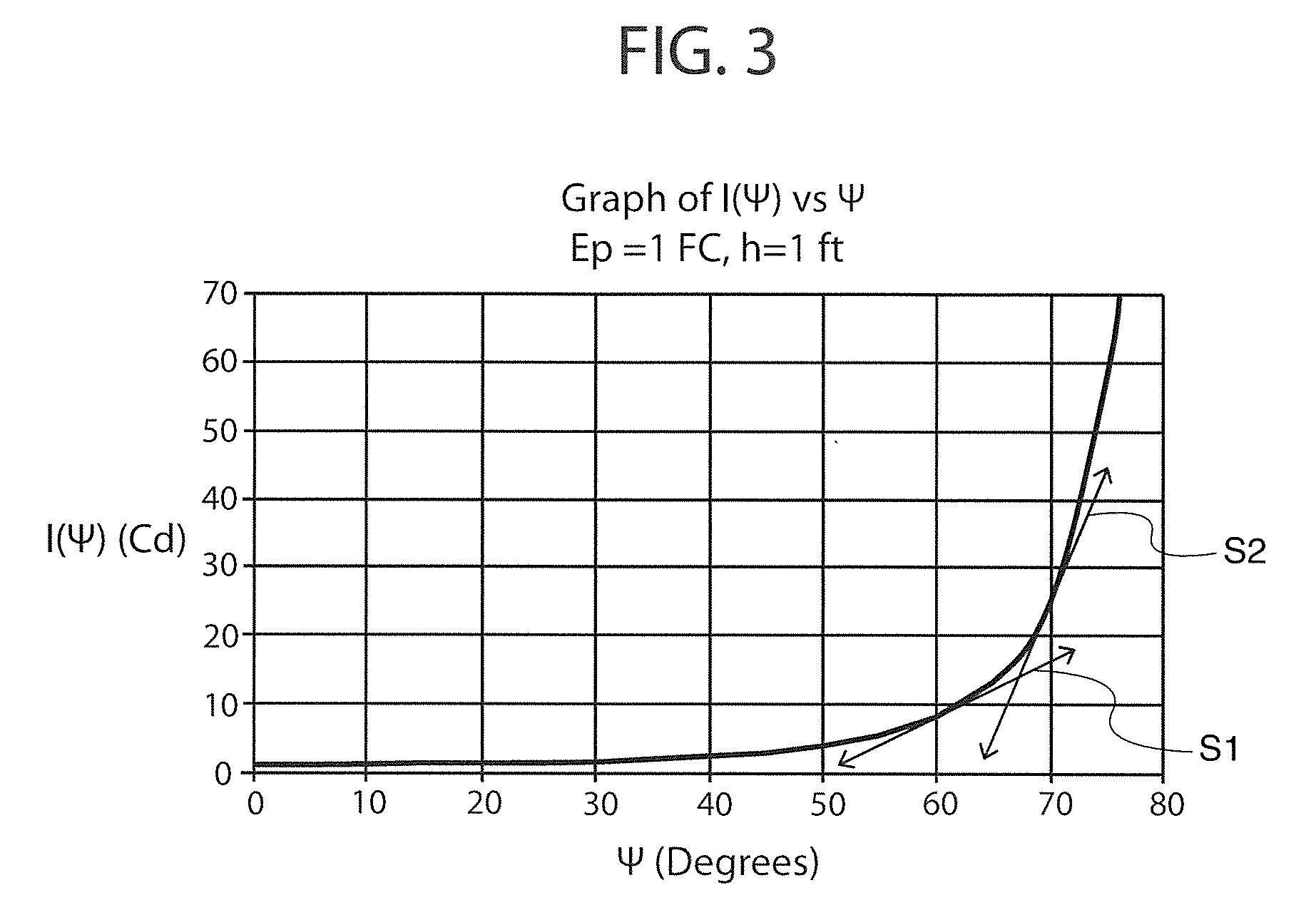

[0076]With reference to FIG. 1, the present invention aims to create a perfect intensity distribution by starting with the following equation for illuminance Ep at point P, where the point or location P is on target area or surface TP (x-y plane) illuminated by a light source or Luminaire L a distance h above (or away from the source) along z axis (or Nadir).

Ep=I(Φ,Ψ)*cos(ξ) / D2 Eqn (1)

[0077]where P=point or location on x-y plane

[0078]np=normal to point P on x-y plane

[0079]h=vertical distance along z axis from luminaire L to target (x-y) plane containing point P (in ft)

[0080]D=distance from luminaire to point P (in ft)

[0081]Φ=lateral angle from 0° Hz (y-axis) to point P (in ft)

[0082]Ψ=vertical angle from Nadir to point P (in ft)

[0083]I(Φ,Ψ)=intensity of luminaire L in direction of point P (in Candela or Cd)

[0084]ξ=angle between np and I(Φ,Ψ) or the incidence angle

[0085]Ep=Illuminance at point P (in Footcandles or FC)

[0086]For simplicity sake, it is assumed that the target plane TP ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com