Heat pump with microchannel heat exchangers as both outdoor and reheat exchangers

a heat exchanger and microchannel technology, applied in the field of heat pumps, can solve the problems of inability to accumulate in a microchannel heat exchanger with a much smaller internal volume, disadvantage on occasion, and excessive charge which may migrate from other refrigerant system components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

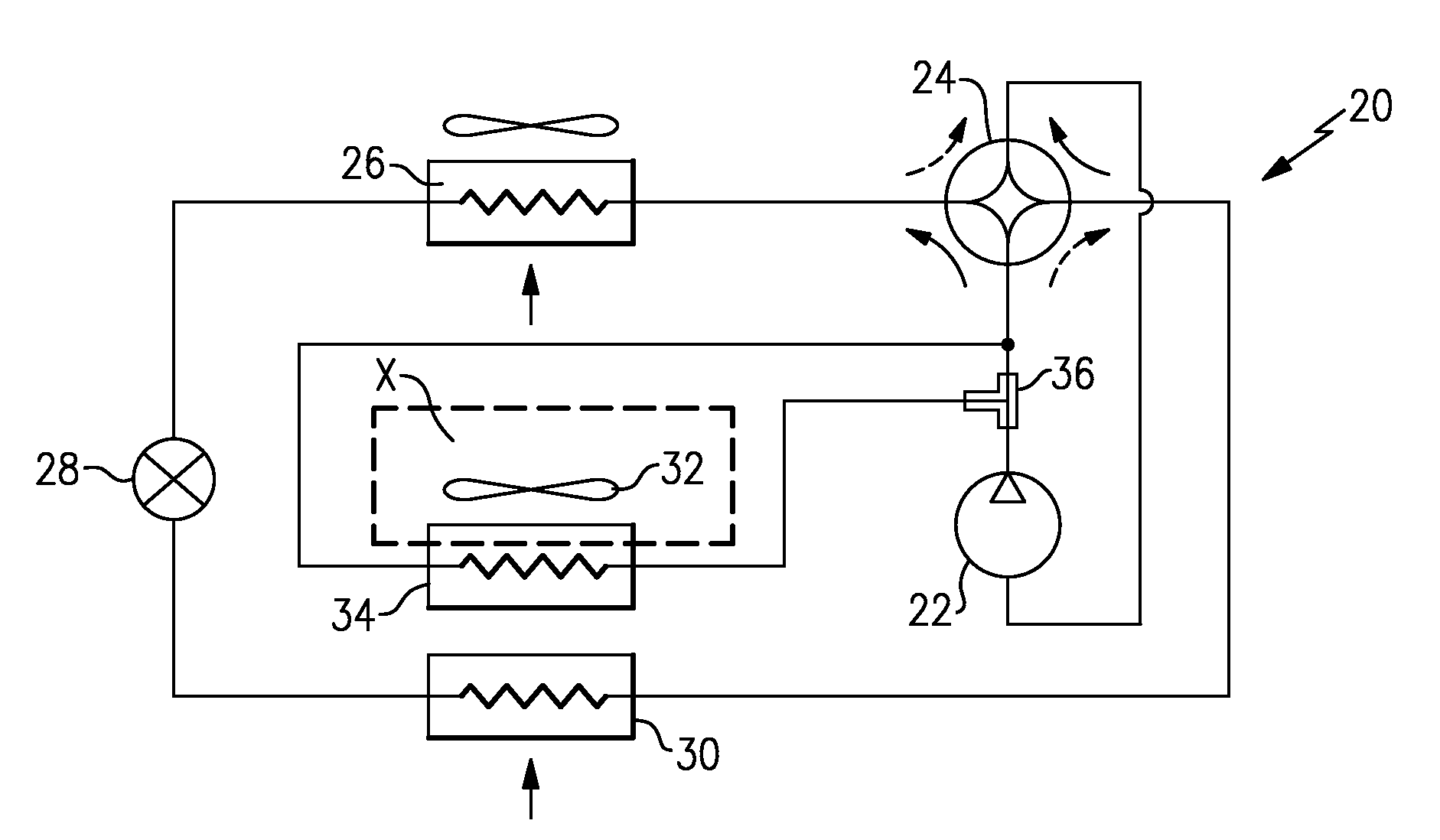

[0015]FIG. 1 shows a heat pump refrigerant system 20 wherein a compressor 22 compresses a refrigerant and delivers it through a reversing refrigerant flow control device such as a four-way reversing valve 24. The four-way reversing valve 24 routes the compressed refrigerant to an outdoor heat exchanger 26 when the heat pump refrigerant system 20 is in a cooling mode of operation. Downstream of the outdoor heat exchanger 26, the refrigerant passes through an expansion device 28, and then through an indoor heat exchanger 30. As known, if the heat pump 20 is operated in a heating mode, the four-way reversing valve 24 is controlled to route the refrigerant first to the indoor heat exchanger 30, the expansion device 28, and then to the outdoor heat exchanger 26. In both modes of operation, the refrigerant is returned to the four-way reversing valve 24 and routed back to the compressor 22. The expansion device 28 can be a single bi-directional expansion device or a pair of unidirectional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com