Closure and method of using same

a technology of operating member and compression force, applied in the field of closure, can solve the problems of containment failure, poor performance in such a demanding environment, and the failure of the closure, and achieve the effect of increasing the compression stiffness of the operating member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

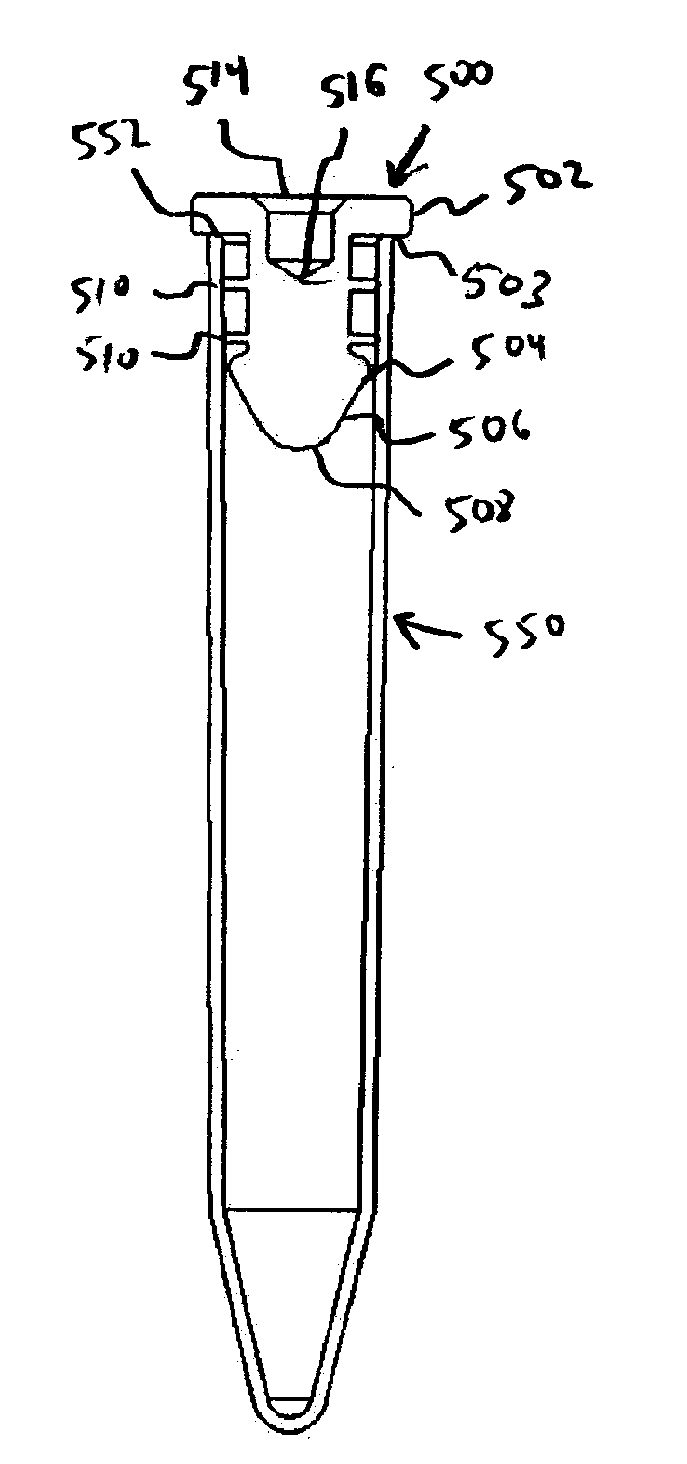

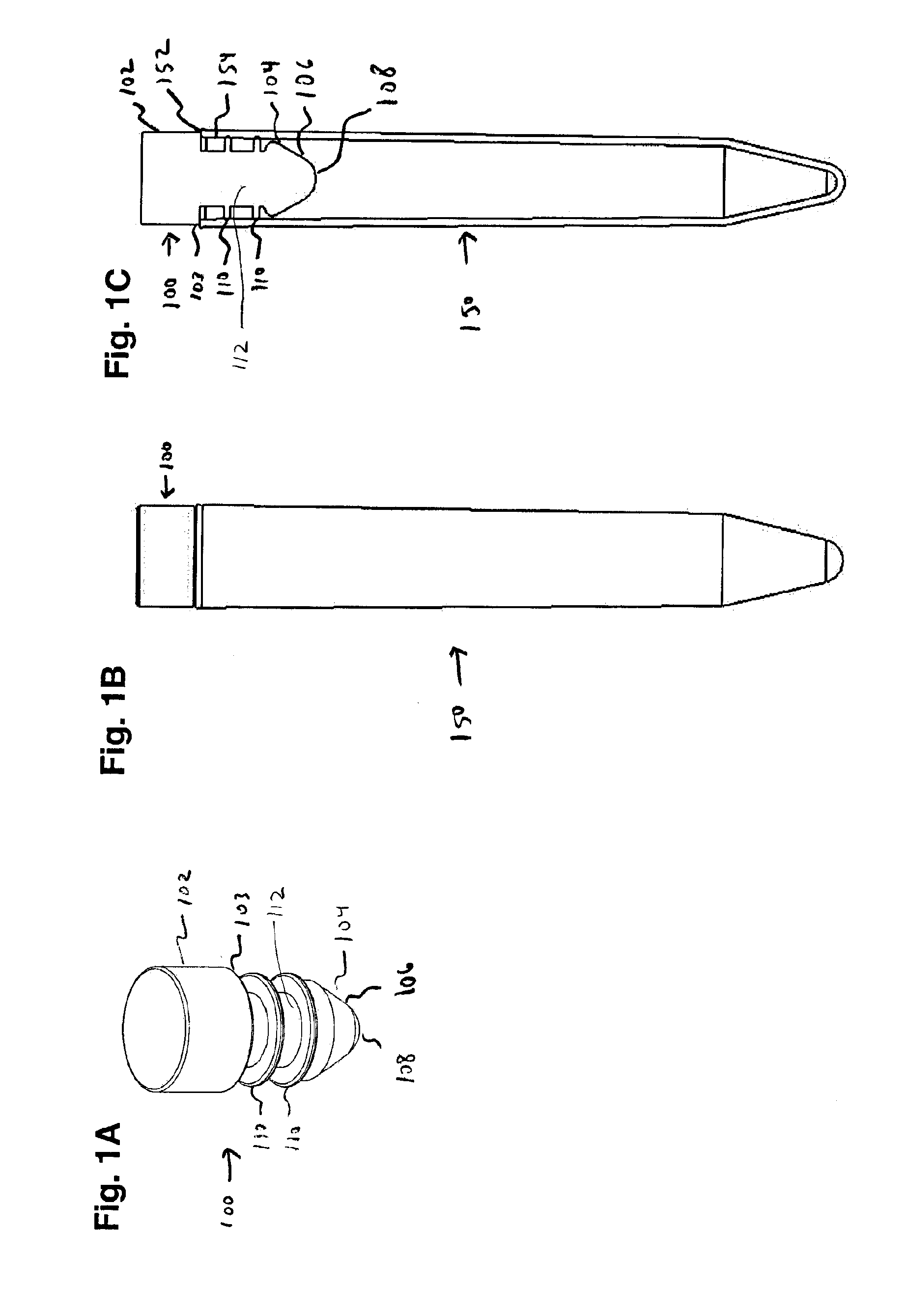

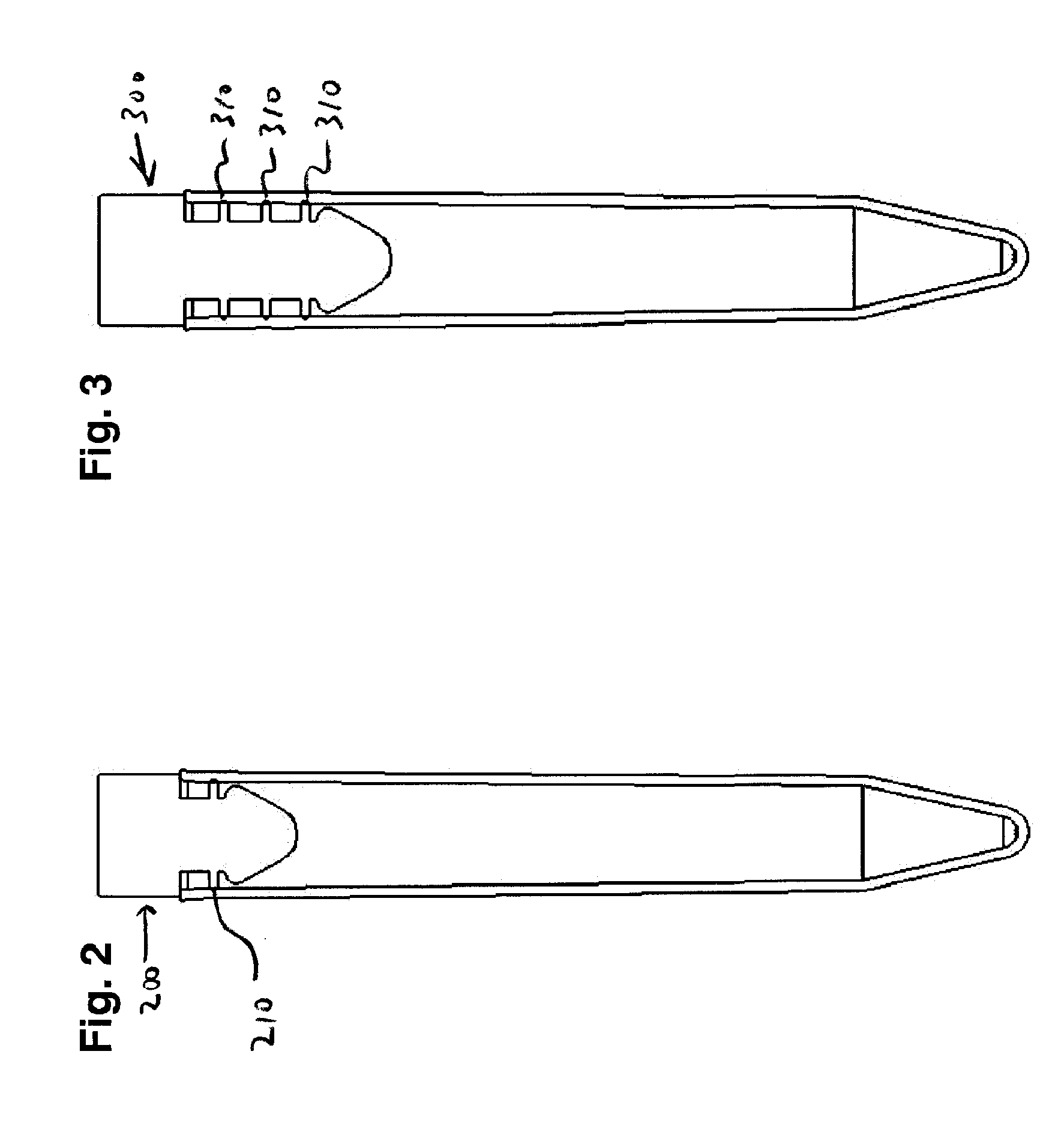

[0022]The embodiments described below generally relate to closures that include one or more of a rigid operating member, a centering member, one or more sealing members, and one or more alignment features. These closures can give excellent performance in automated and manual operation. As noted above, many conventional closures are insufficiently reliable for use in a demanding environment, due to insufficient rigidity (leading to distortion during use), excessive rigidity (leading to inability to accommodate misalignment during insertion), and other shortcomings. To address these problems, the present closures include a rigid operating member and features that can prevent misalignment and / or features that can correct misalignment during insertion (examples of such features are described in further detail below).

DEFINITIONS

[0023]“Operation” of a closure refers to insertion of a closure into a complementary opening or removal of a closure from a complementary opening, as well as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com