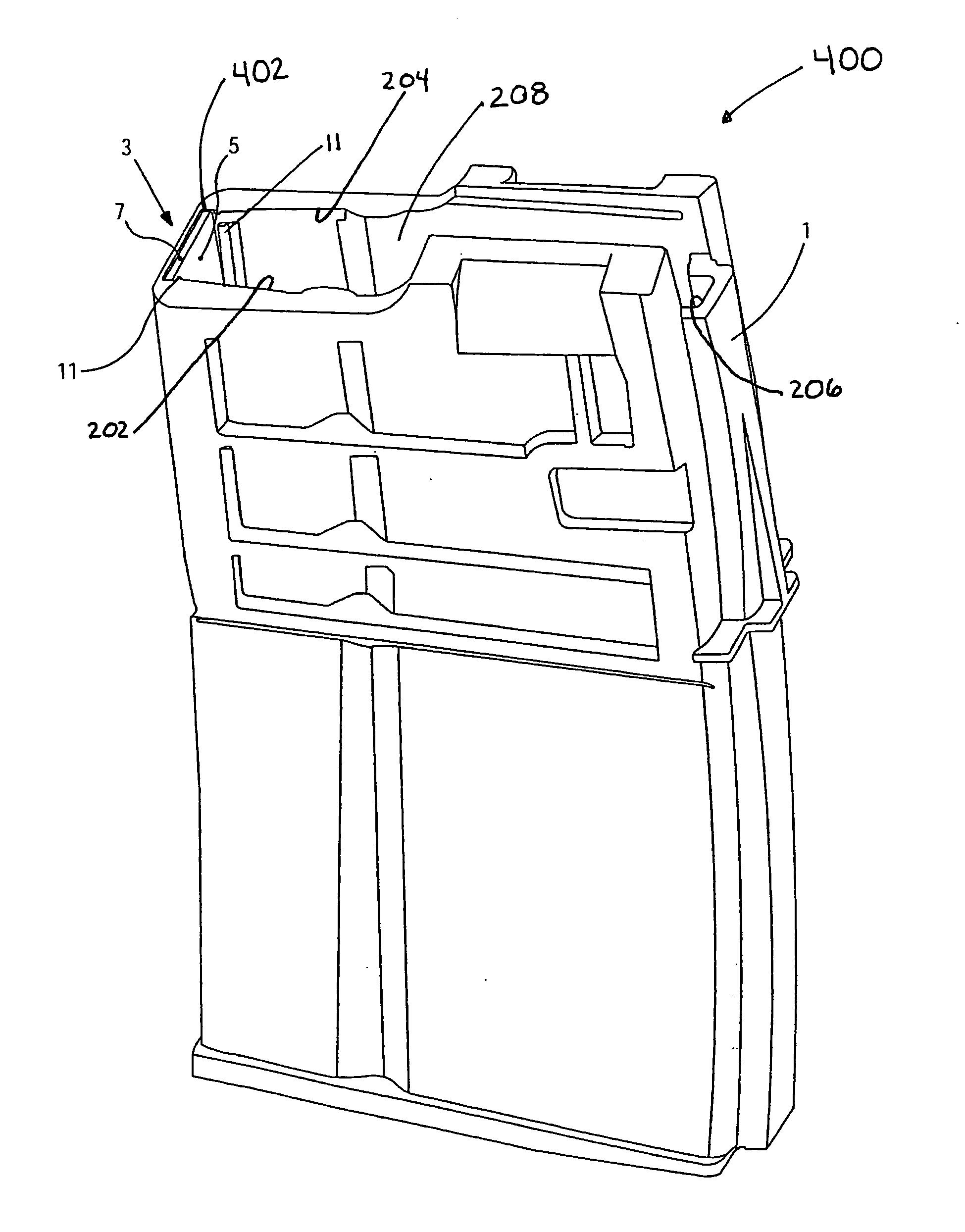

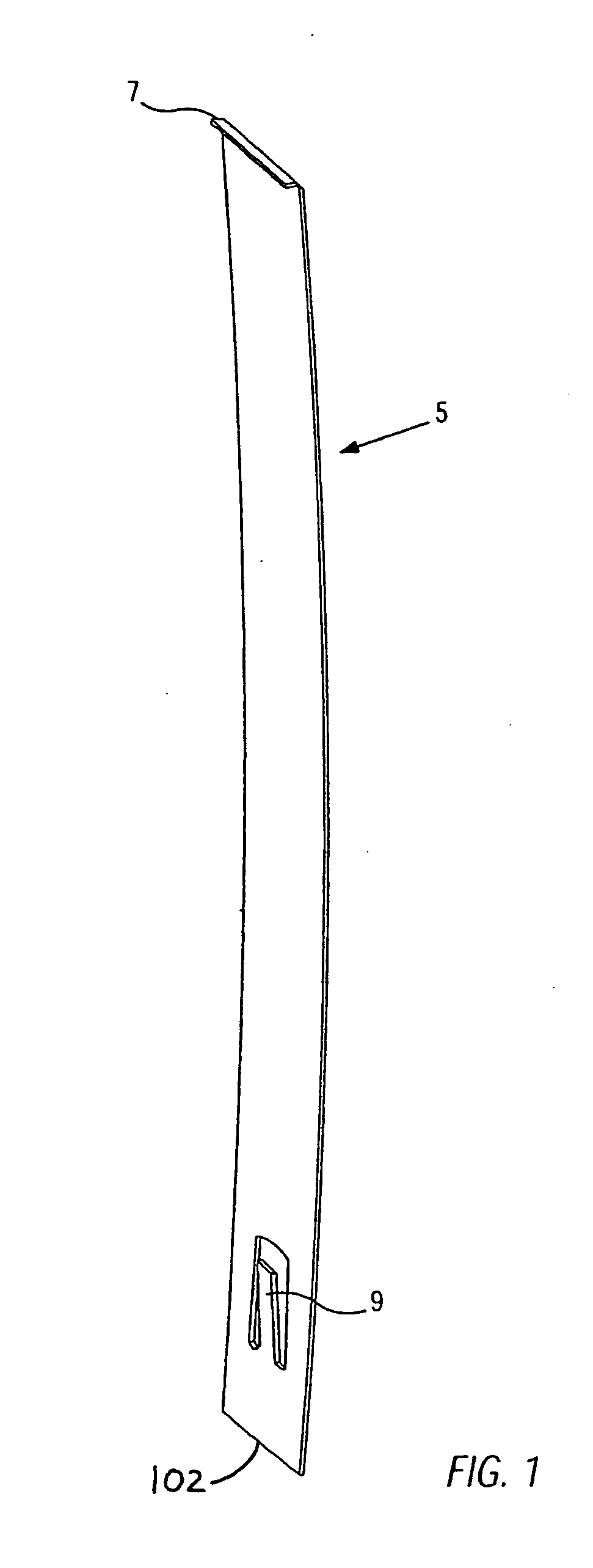

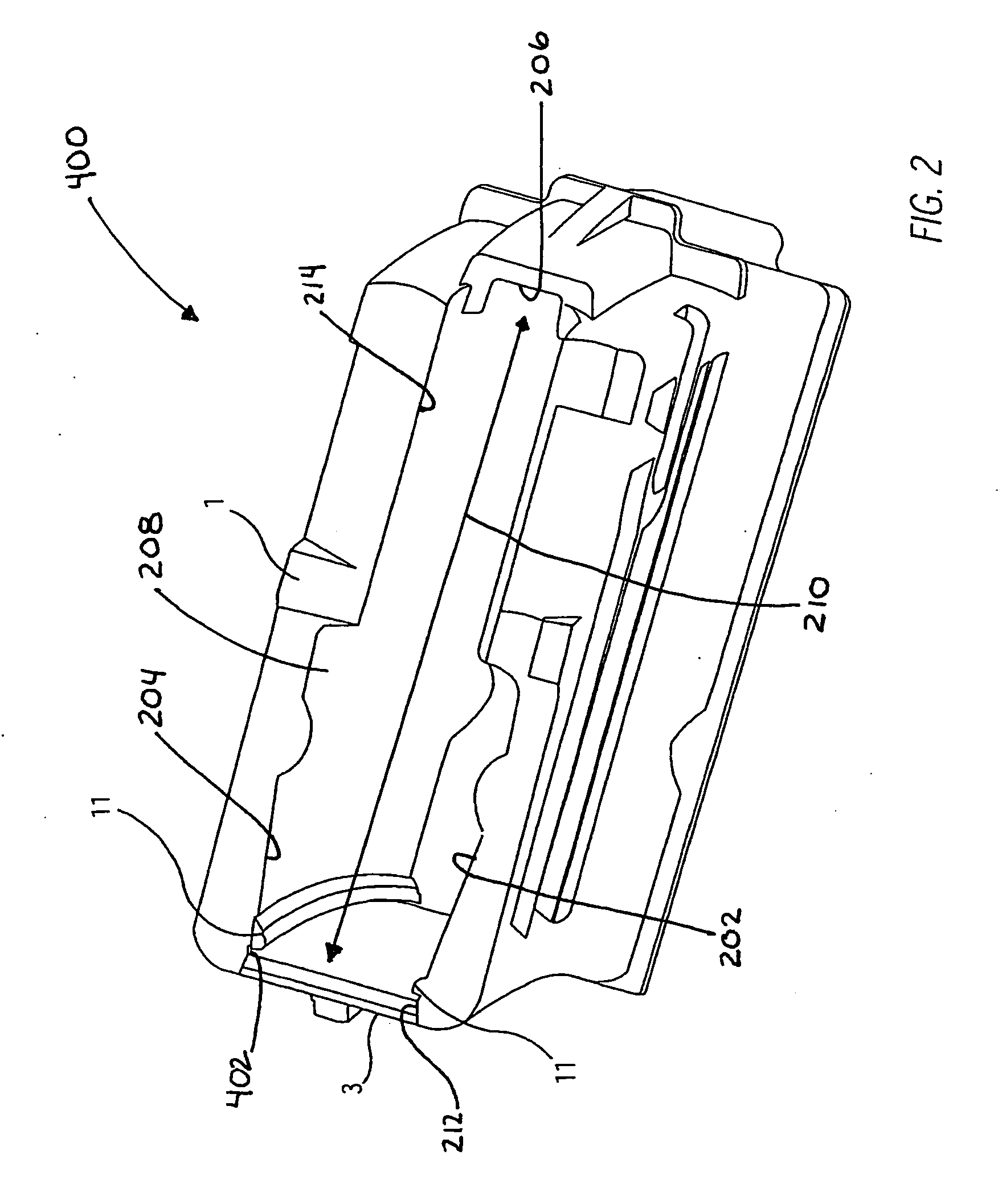

Plastic magazines for use with firearms

a technology for firearms and plastic magazines, applied in the field of plastic magazines, can solve the problems of tensile dent, marksmen may not identify this defect, and plastic magazines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]Certain examples are shown in the above-identified figures and described in detail below. In describing these examples, like or identical reference numbers are used to identify the same or similar elements. The figures are not necessarily to scale and certain features and certain views of the figures may be shown exaggerated in scale or in schematic for clarity. Additionally, several examples have been described throughout this specification. Any features from any example may be included with, a replacement for, or otherwise combined with other features from other examples. Further, throughout this description, position designations such as “above,”“below,”“top,”“forward,”“rear,”“left,”“right,” etc. are referenced to a firearm held in a normal firing position (i.e., wherein the “shooting direction” is pointed away from the marksman in a generally horizontal direction) and from the point of view of the marksman. Furthermore, the normal firing position of the weapon is always as...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap