Sterile sampling methods and apparatus

a sampling method and liquid technology, applied in the field of sterile sampling methods and apparatuses, can solve the problems of contamination of liquid and inability to carry through to the liquid in the pouch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

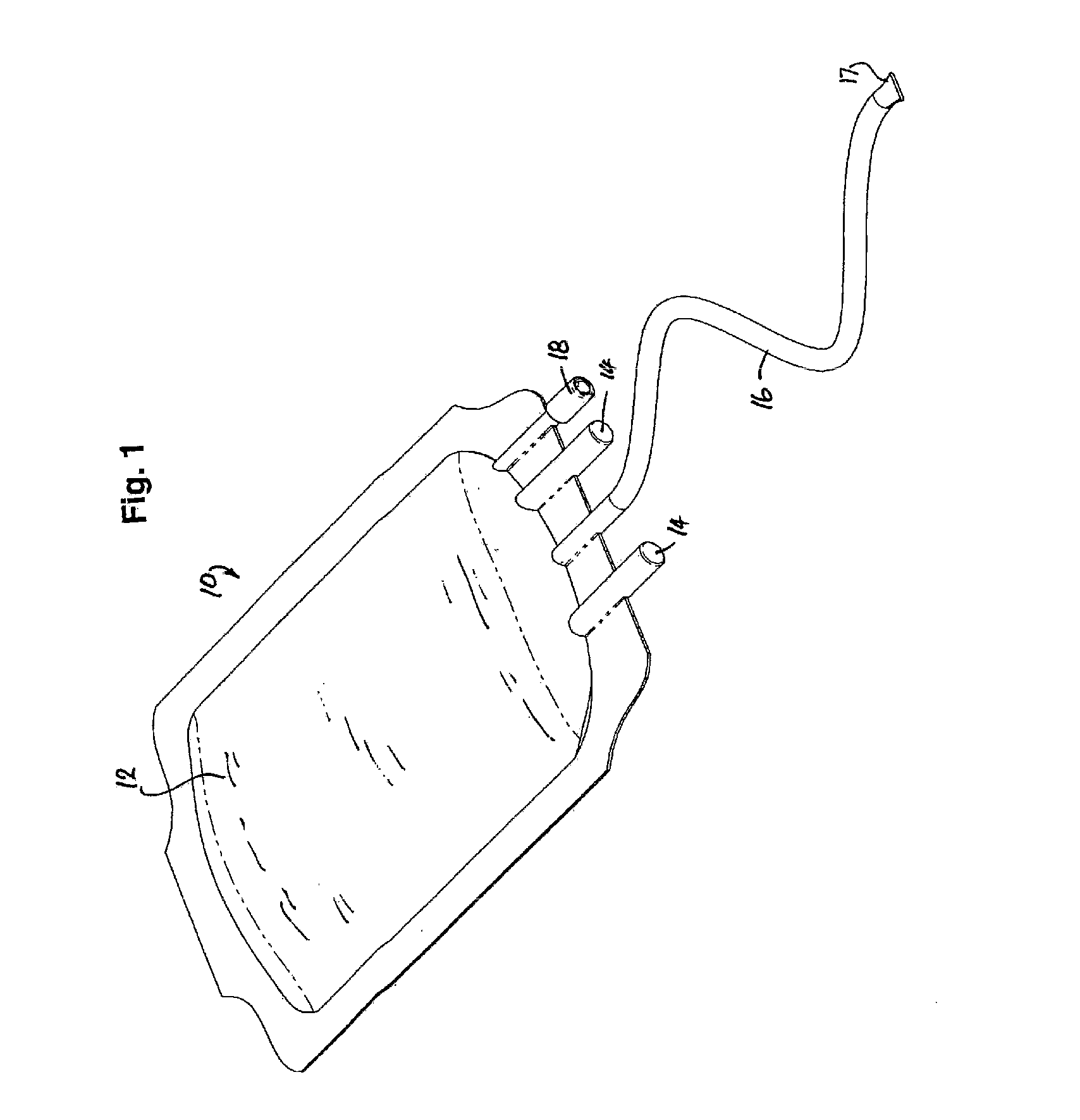

[0027]FIG. 1 shows a liquid container comprising a conventional sealed plastic pouch 10 containing a unit of platelets liquid, generally indicated at 12. Pouch 10 may have blanked-off tube connections 14 that may have been used during collection of the platelets but it will generally have at least one attached outlet or pouch tube 16 that is heat-sealed at its free end 17. Pouch 10 may also be provided with a split-septum needless port 18 through which a hollow blunt cannular can be inserted to extract samples of liquid 12. Samples of liquid may also be drawn from tube 16 by the use of a syringe and sharp medical needle. As already noted, both these methods of withdrawing samples involve contamination risk, both to the extracted sample and to the liquid in the pouch.

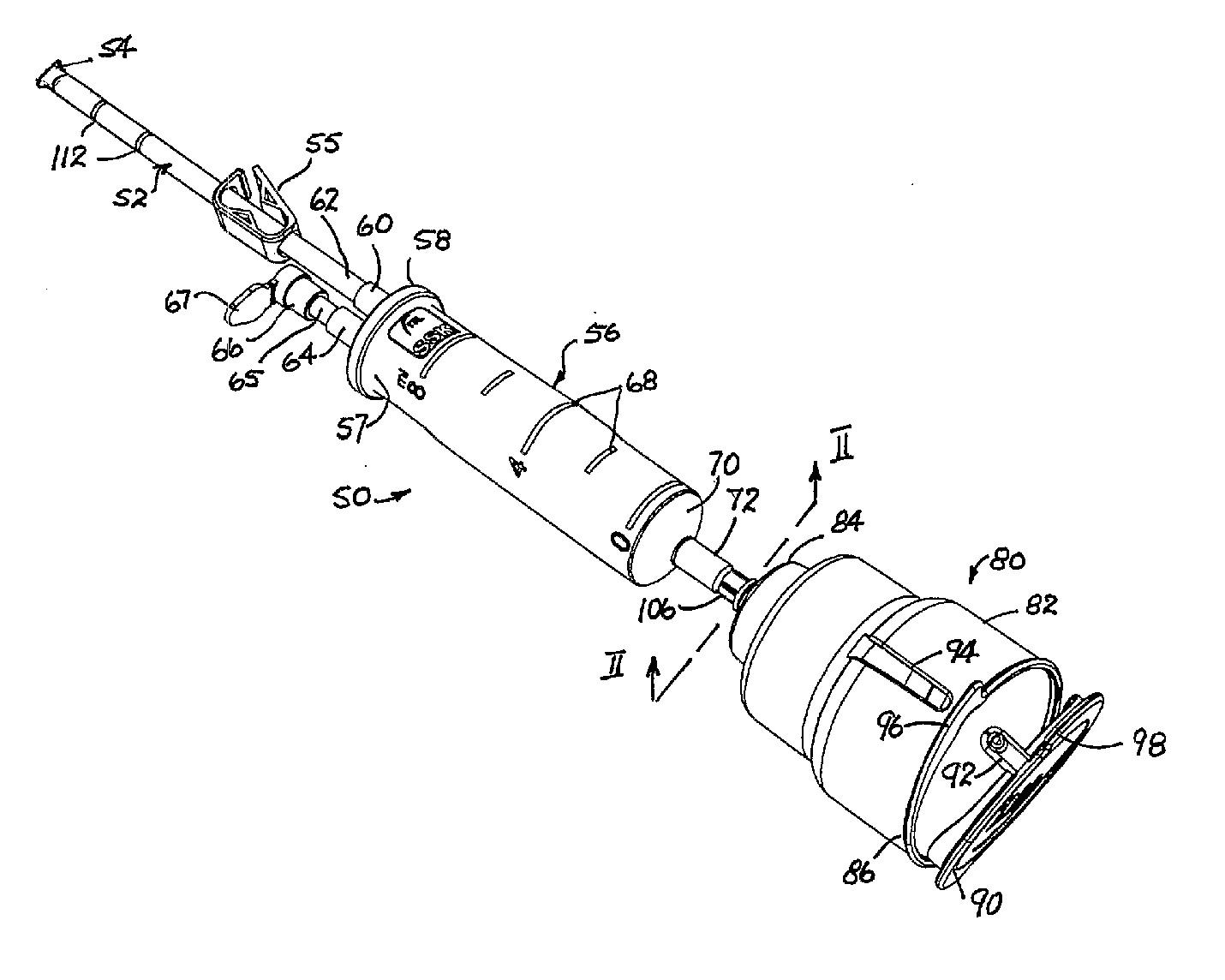

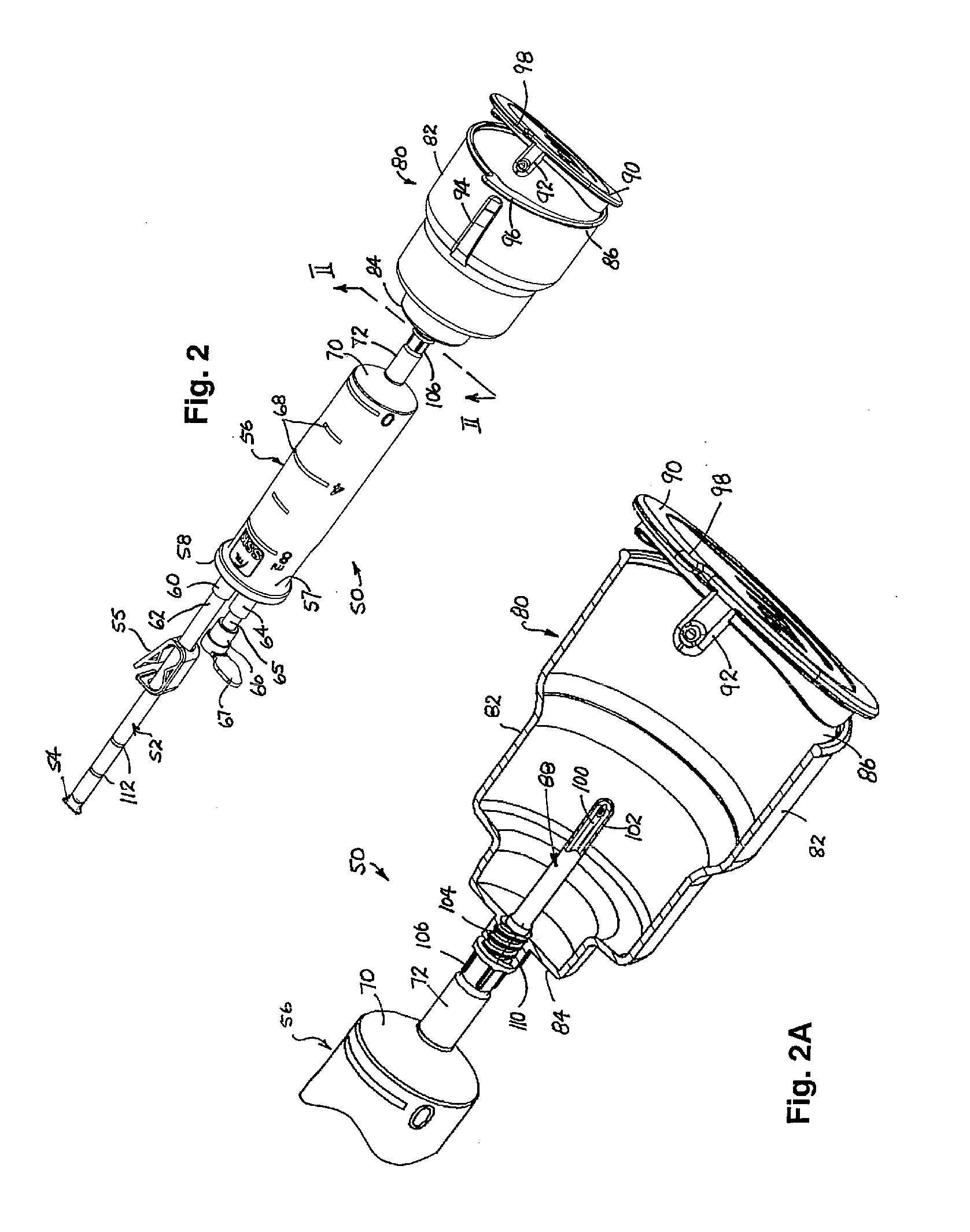

[0028]Turing now to FIGS. 2, 2A and 3, the apparatus 50 of the preferred embodiment will now be described. Apparatus 50 is preferably supplied as a sterile unit. It has a plastic inlet or sample tube 52 that is that is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com