Vacuum process apparatus

a technology of vacuum process and vacuum chamber, which is applied in the direction of lighting and heating apparatus, charge manipulation, furnaces, etc., can solve the problems of lack of flexibility, and achieve the effect of minimizing the cycle time of processing, minimizing the space possible, and high construction flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

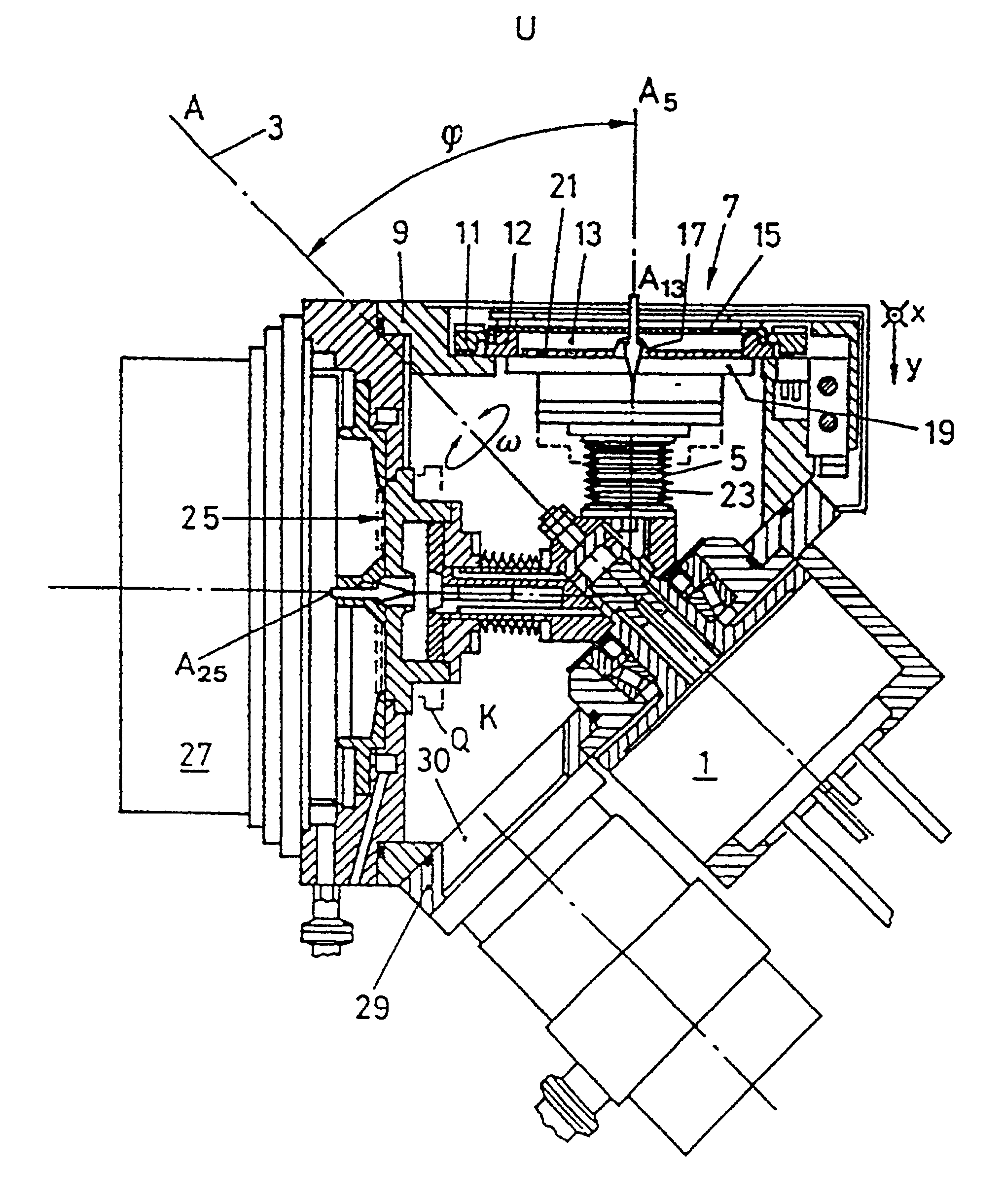

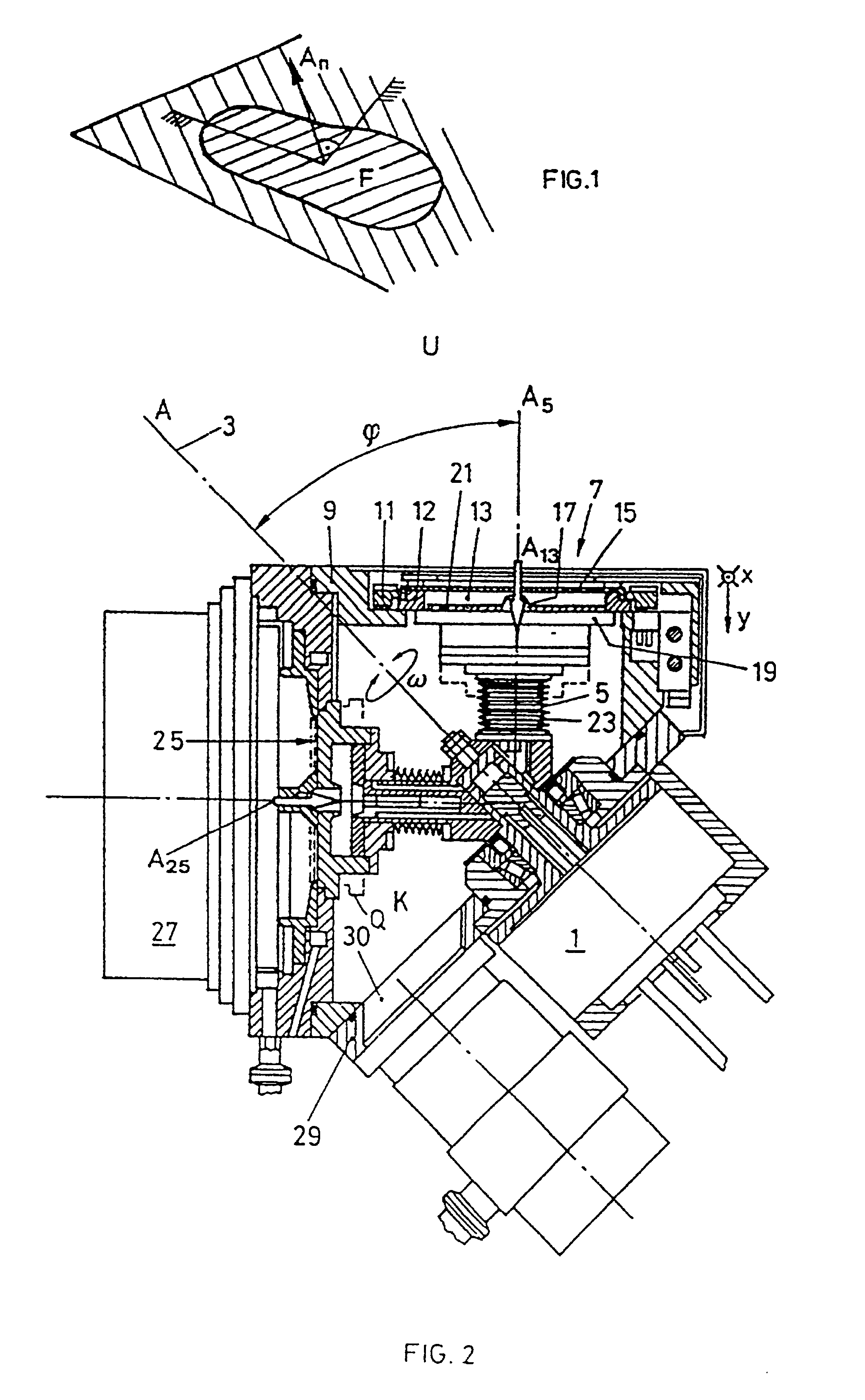

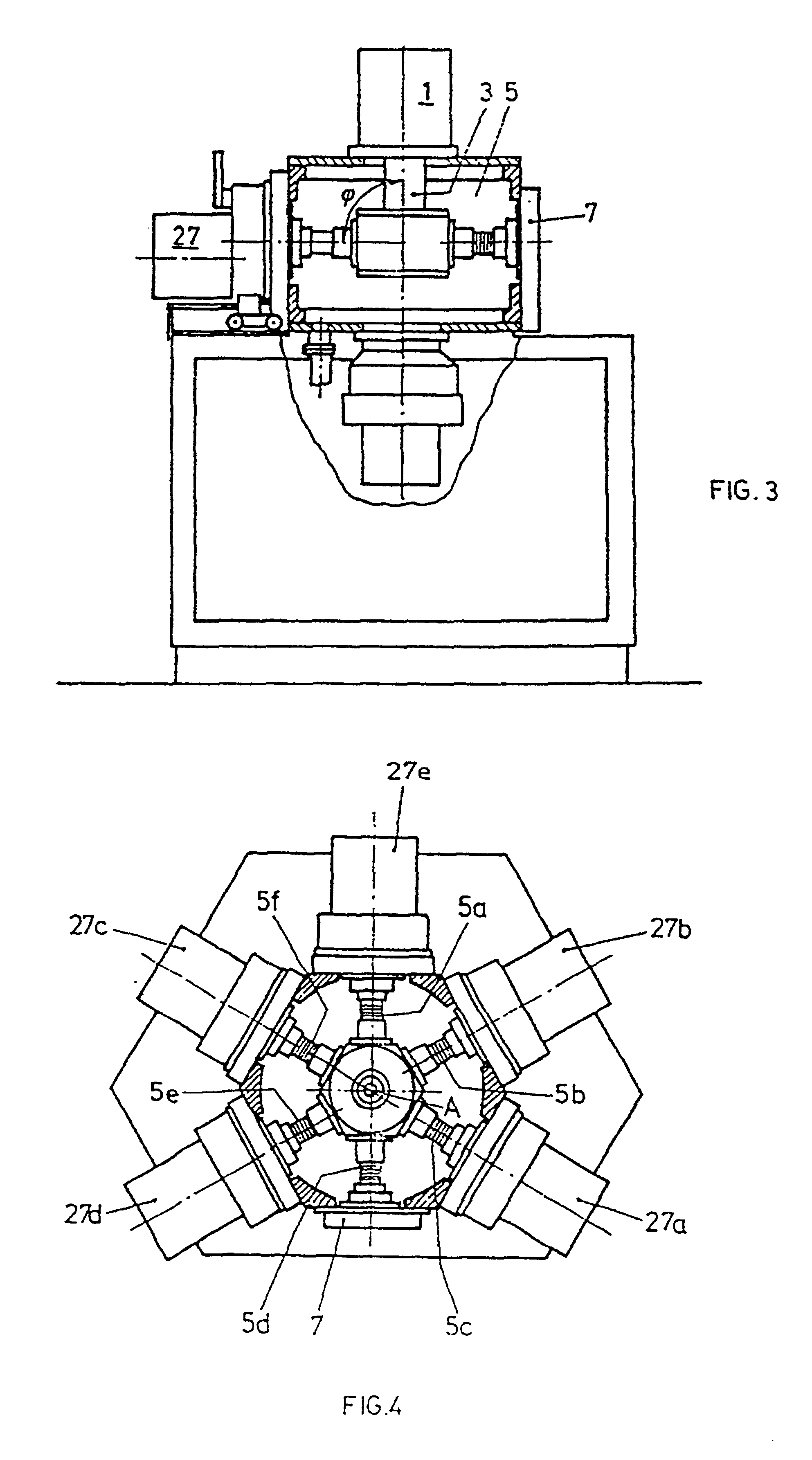

[0043]FIG. 2 is an illustration designed in section of an inventive vacuum process apparatus in a first configuration. It includes a drive motor 1 on the axis A as physical drive axis 3, to which at least one transport arm 5 is mounted. The axis A5 of the arm 5 extends at an angle, for instance of 45° relative to the rotation axis A. If the drive axis 3 is caused to rotate by means of the motor 1 such as indicated by ω, the transport arm(s) 5 sweeps over a conical trajectory surface having a cone angle φ of 45°. Two stations are illustrated in FIG. 2. A first station 7 is for instance and as illustrated designed as load lock. It includes a first frame 9 and a second frame 11 which can be moved upwards and downwards and which is flanged onto the first frame 9. Inside of the drivingly upwards and downwards movable frame 11 a sealing frame 12 is provided which determines the opening 13 of the station and thus its area, having a surface normal A13 of said area. The lock station 7 includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cone opening angle | aaaaa | aaaaa |

| opening angle | aaaaa | aaaaa |

| cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com