Drillstring motion analysis and control

a technology of drillstring and motion analysis, applied in the direction of survey, instrument, borehole/well accessories, etc., can solve the problems of reducing drilling efficiency, reducing drilling efficiency, and causing chaos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

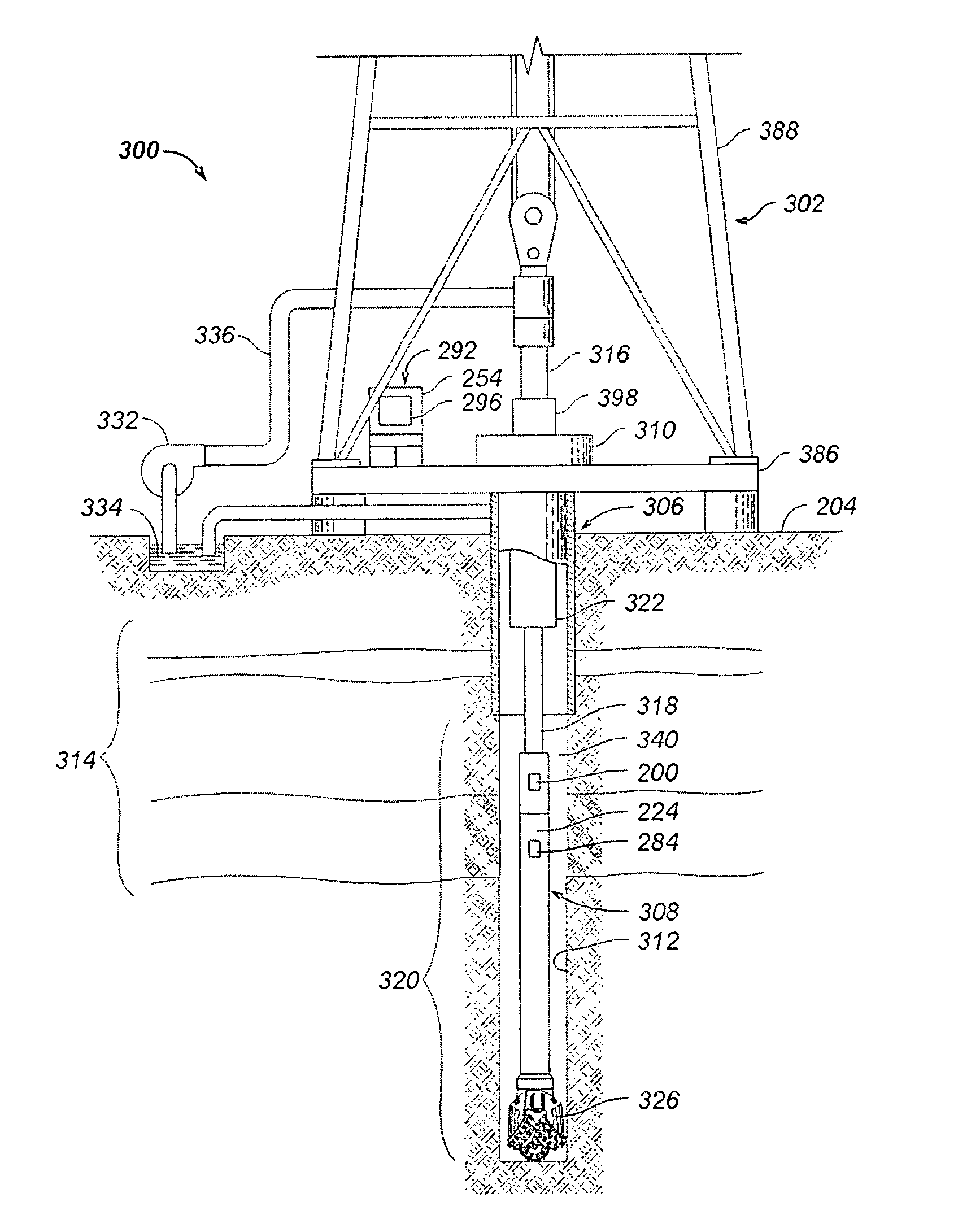

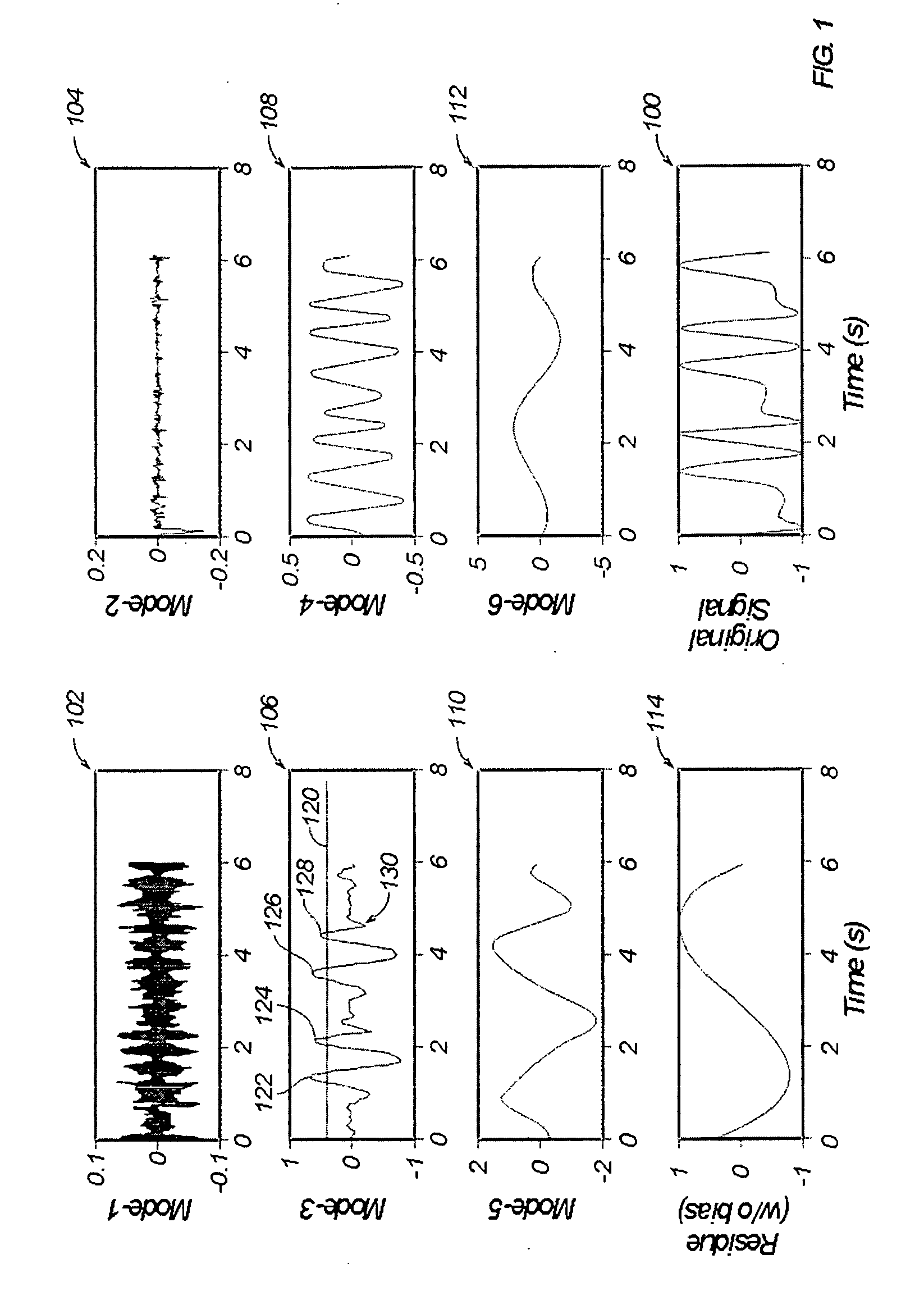

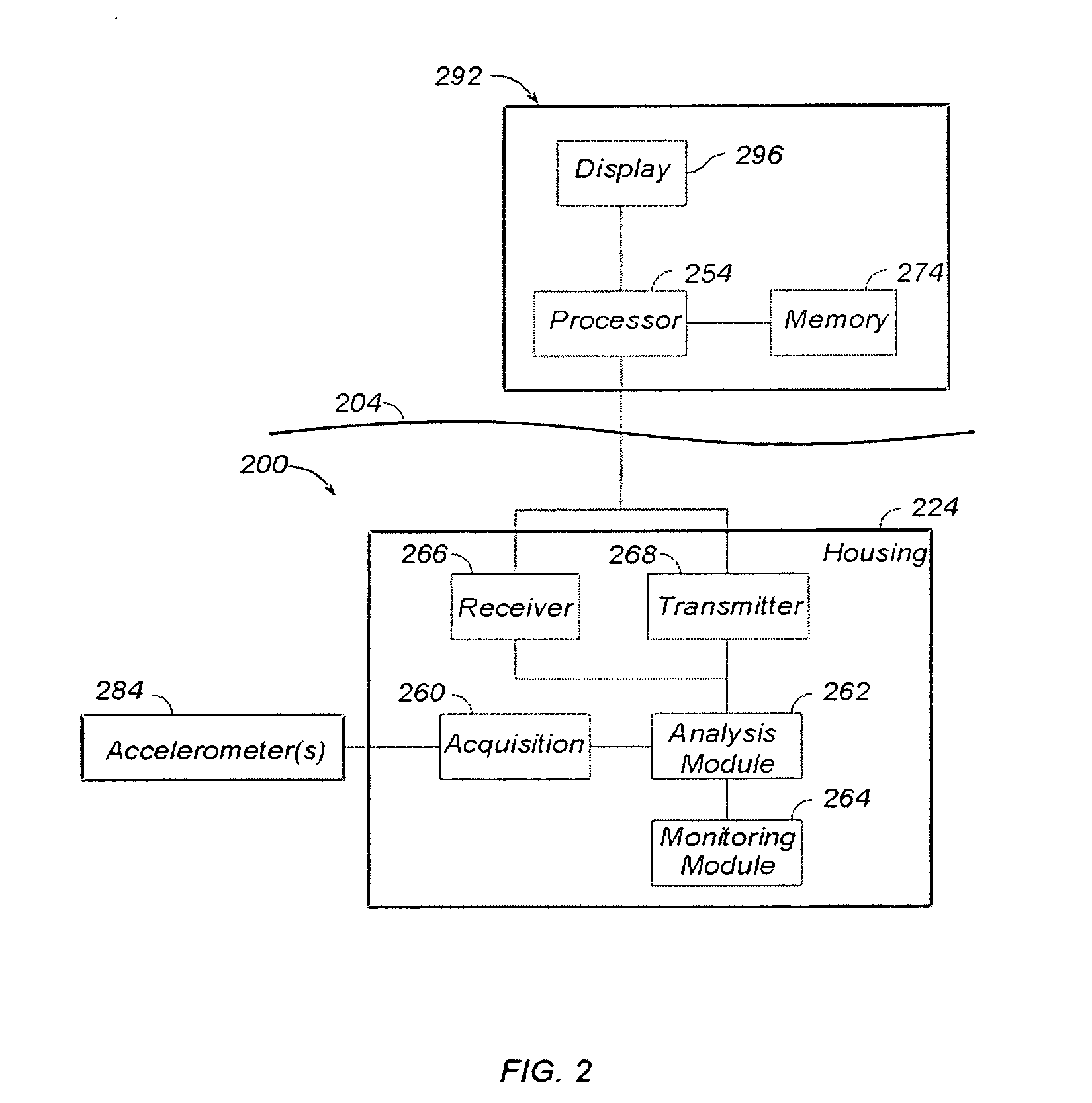

[0007]Time series measurements made using accelerometers and other motion-sensitive sensors can be used to diagnose undesirable vibration phenomena that occur as part of drilling operations. Because of inter-related effects, a reliable diagnosis can be difficult to make when several phenomena exist simultaneously. However, if enough motion-sensitive sensors are used, along with instrumentation for real-time standoff measurements, the various modes of drillstring motion can be isolated by combining the sensor outputs. Unfortunately, due to constraints on funding and computer resources, this type of operation is not practical.

[0008]As an alternative, a mechanism is disclosed herein that permits identifying various modes of vibrational motion presented by a bottom hole assembly (BHA) using a single measurement vehicle (e.g., a single accelerometer). By deriving modal decomposition information from surface or downhole (or both) acceleration sensors, and identifying / correlating the behav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com