Reservoir filling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0005]The object of the invention is to provide a filling device which is easy to handle for the user, simple and non-expensive to manufacture and where the risk of breaking the venting needle during the filling process has been eliminated.

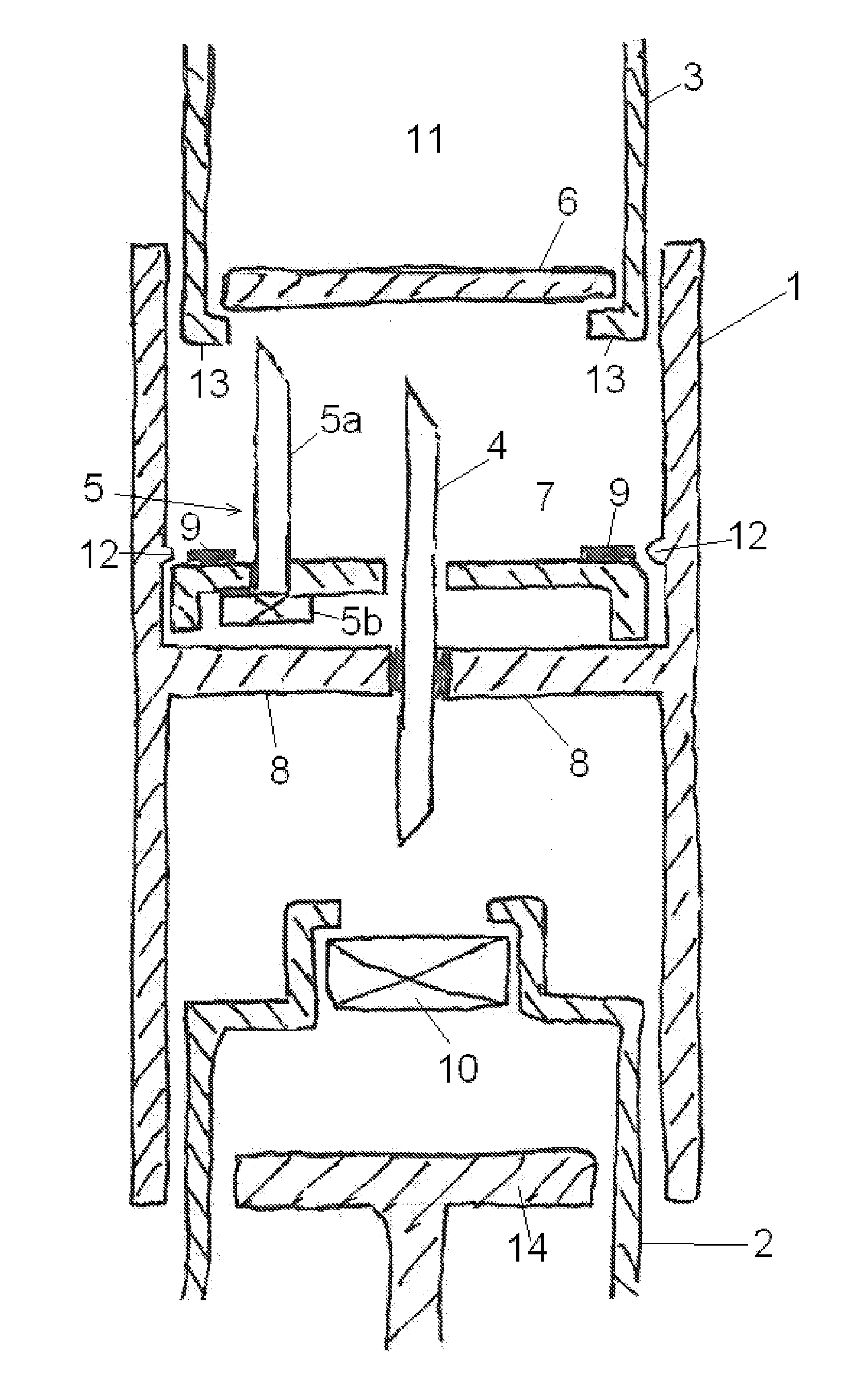

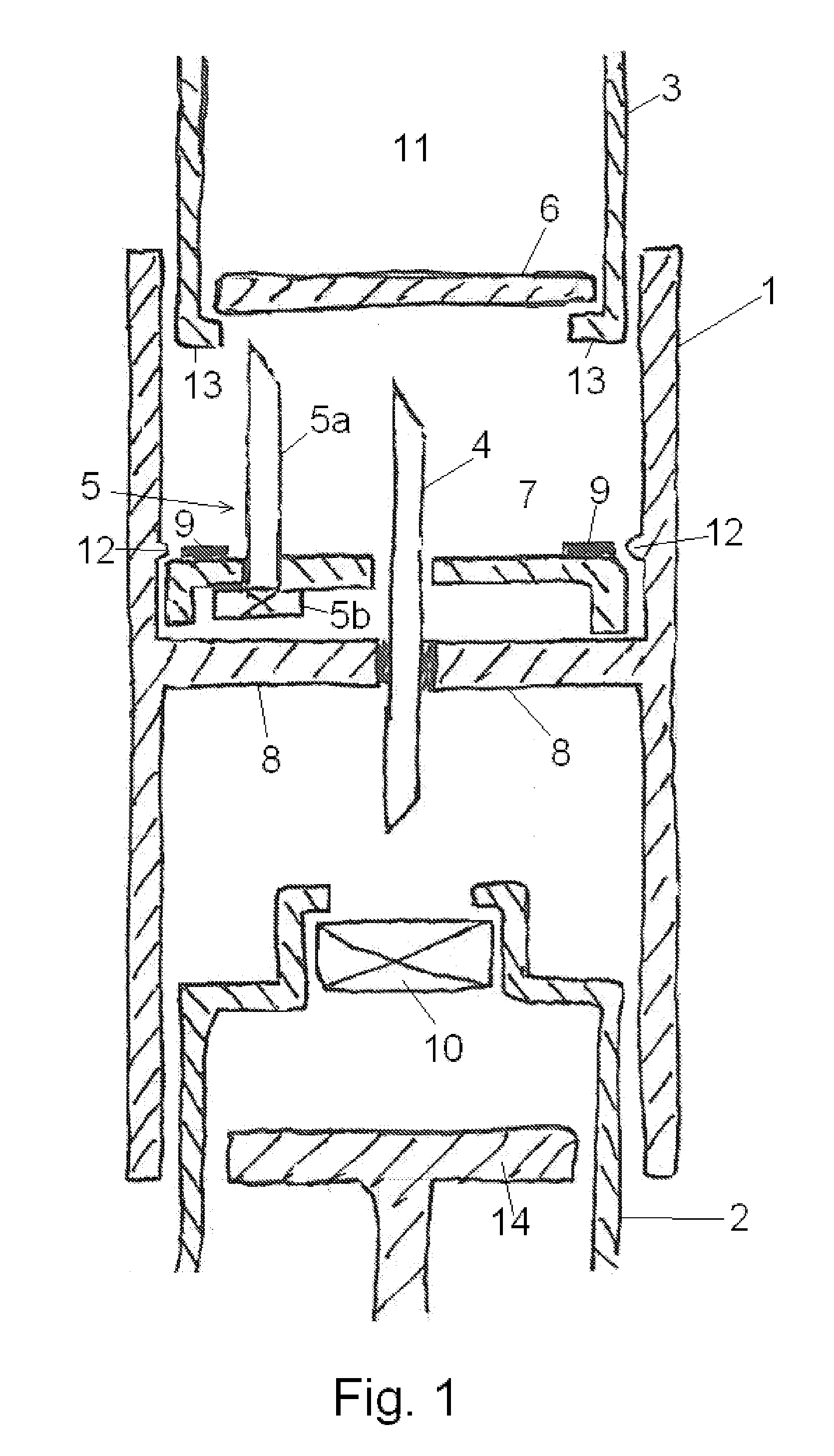

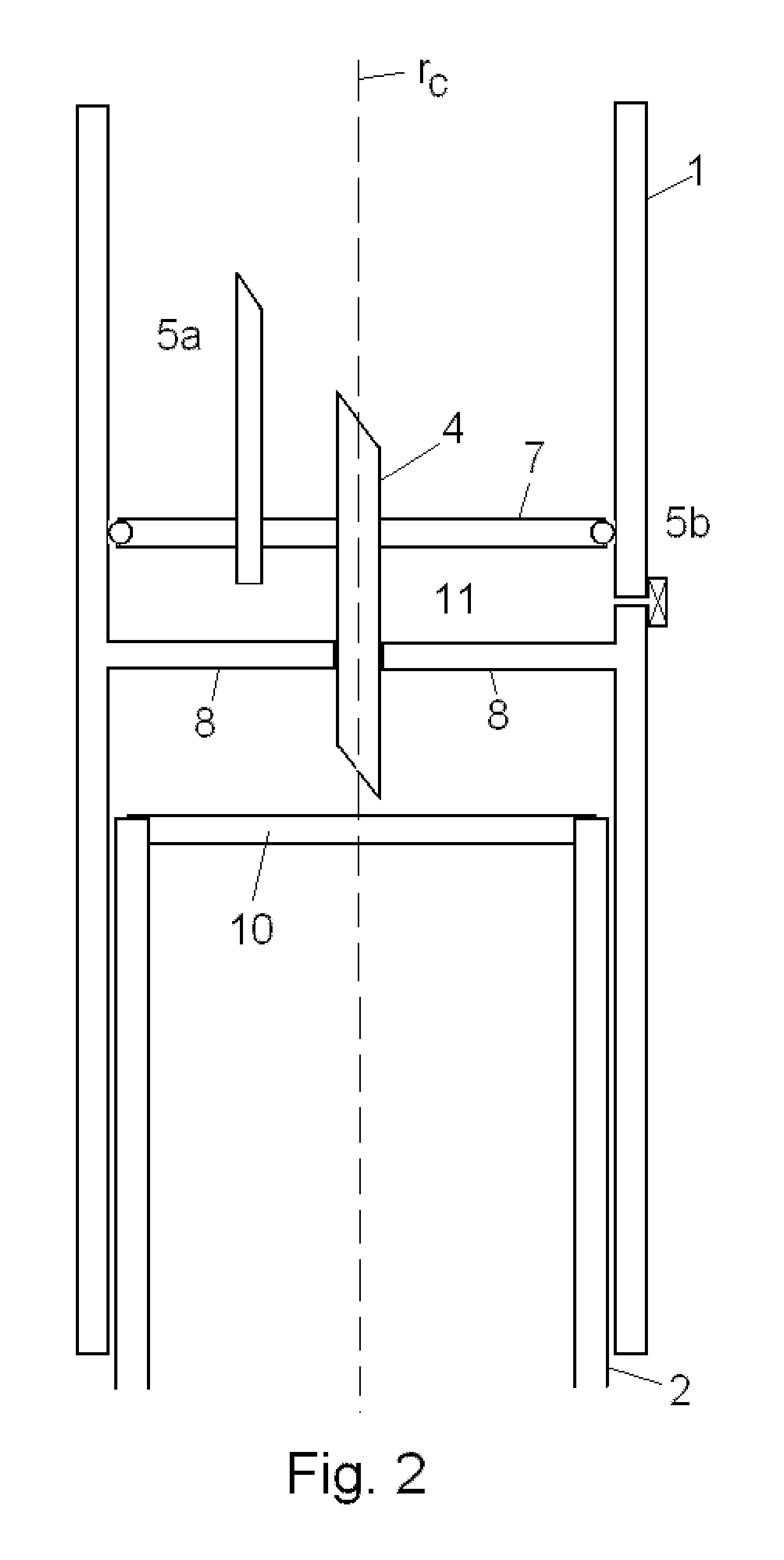

[0006]The invention concerns a filling device which comprising[0007]a housing comprising[0008]a first position means adapted to receive a reservoir for receiving liquid,[0009]a second position means adapted to receive a cartridge containing a liquid,[0010]a unit unreleasably attached to the housing and providing a flow path when both the reservoir and the cartridge are received respectively by the first and second positions means,[0011]a venting unit providing access of gas to the cartridge during emptying of the cartridge, and at least a part of the venting unit is placed off the rotational centre (rc) of the housing and is attached to a part. The invention is characterized in that this part can rotate relative to the housing and relative to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com