Shoe with Anti-Skid Sole

a technology of anti-skid shoes and soles, applied in the field of shoes with anti-skid soles, can solve the problems of the most frequent and serious accidents, and achieve the effects of reducing the retention rate of pebbles, reducing the grip coefficient, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

OF EMBODIMENT

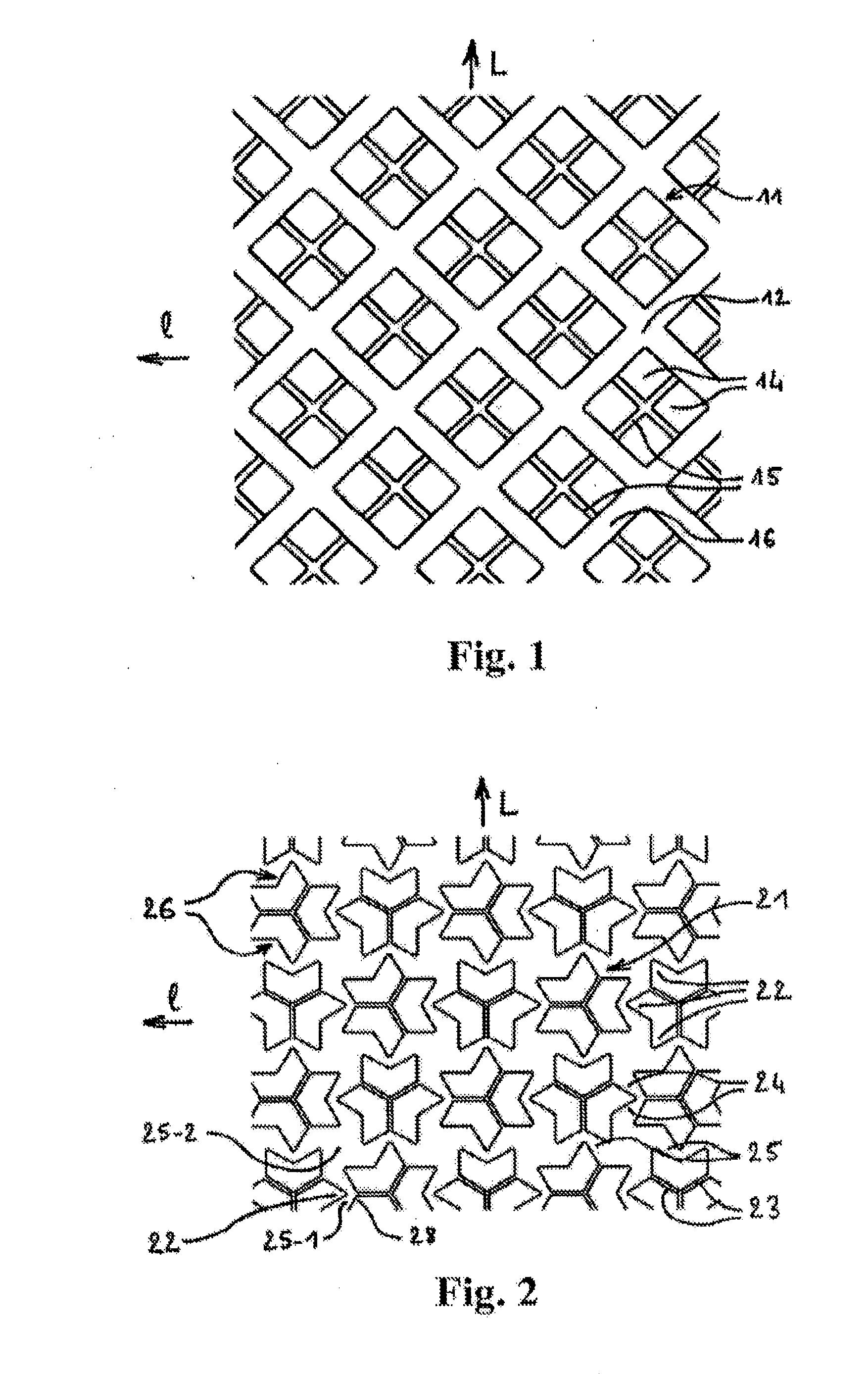

[0043]A sole sculpture is shown in FIG. 1, which reproduces, approximately at least, that of the model document filed in the United States under the number US D446912S, mentioned at the beginning of this text as an illustration of the prior art. It is composed of square rubber lugs 11, which project towards the lower face of the sole from a substrate 12 which has a thickness and suppleness suitable for the intended use of the sole. Each of the lugs 11 is divided into four elementary blocks 14 by two slits or sipes or indentations 15 intersecting at right angles. The lugs 11 are separated from each other by two sets of orthogonal grooves 16 parallel to the slits 15, which have suitable dimensions to allow a good flow of the liquid displaced by the sole in contact with the ground. The width of these grooves is normally several times the width of the internal slits 15 of each lug 11.

[0044]In FIG. 1, the longitudinal direction of the footwear is orientated from the bottom t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com