Connection of a prosthesis structure with an implant structure

a technology of prosthesis structure and implant structure, which is applied in the field of connection devices, can solve the problems of high consumption of retention parts, difficulty and labor, and irregularly not being able to place implant structures exactly at the desired target, and achieves the effects of convenient, comfortable and reliable placement or snapping, and relatively easy replacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

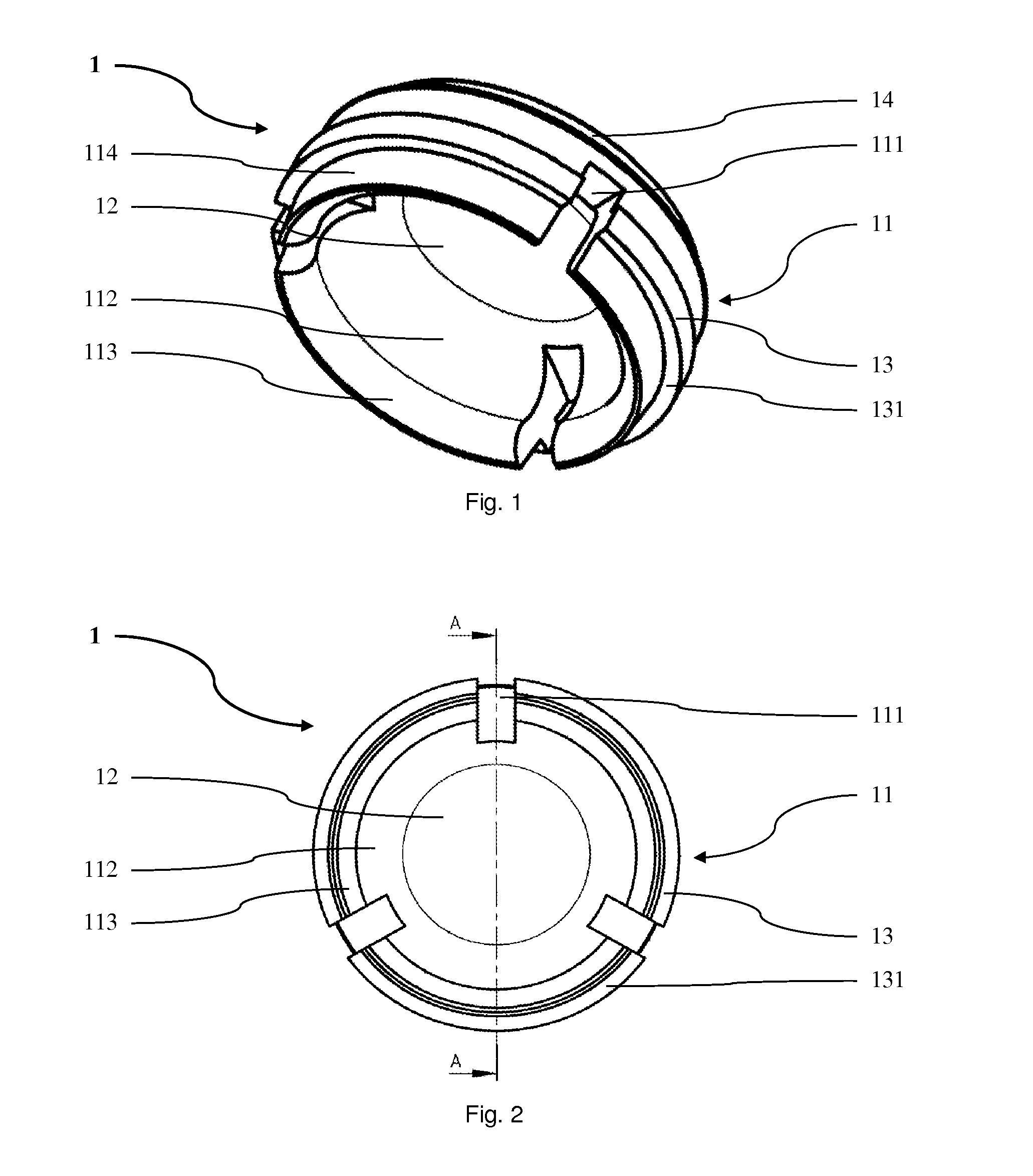

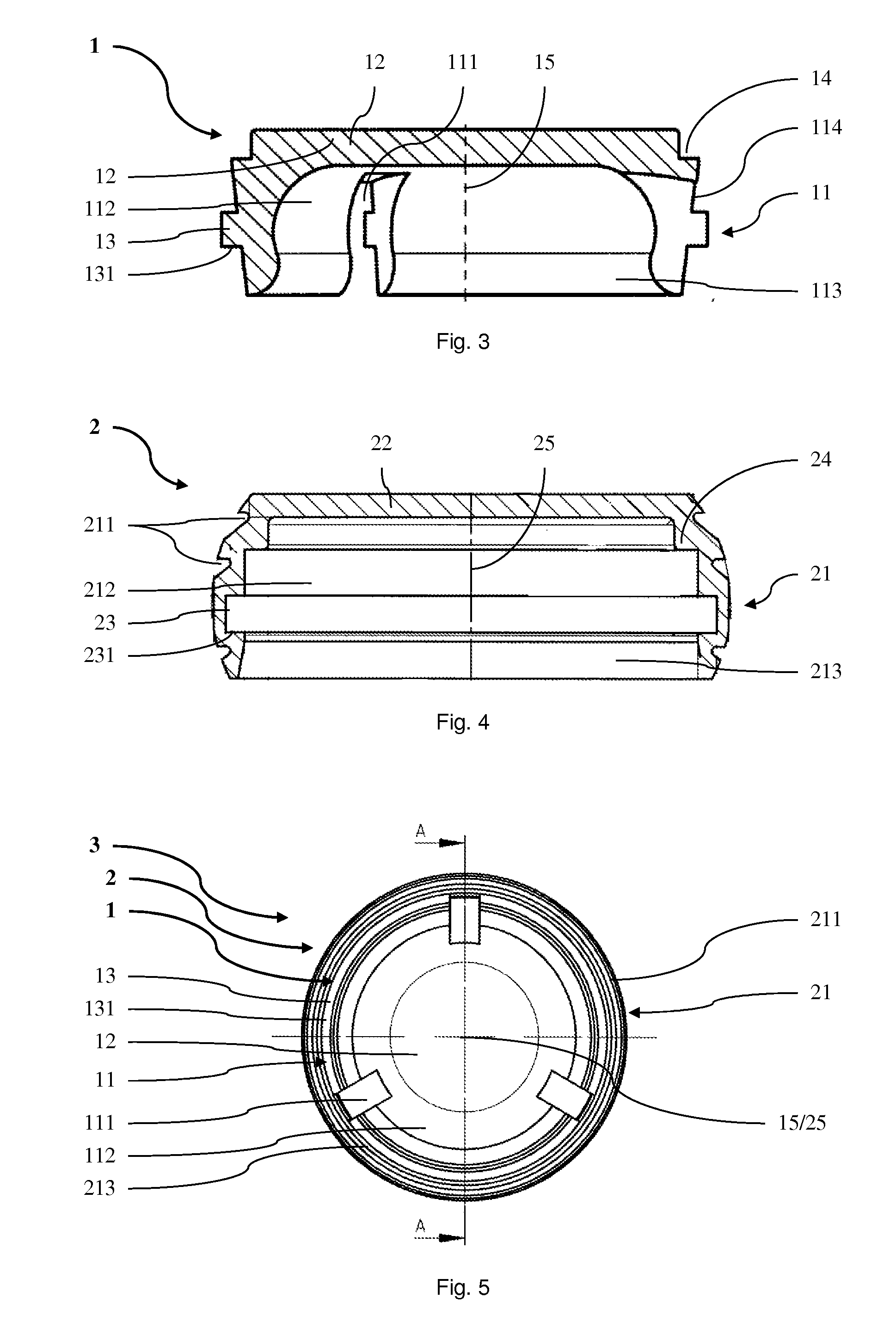

[0041]FIG. 1 shows a retention insert 1 according to the invention. The substantially cup-shaped retention insert 1 comprises a substantially disk-shaped closed end side 12 and a substantially ring-shaped retention rim 11 projecting at the circumference thereof at an angle. The retention rim 11 comprises an outer surface 114, three recesses 111 uniformly spaced from each other in the circumferential direction, and lamella portions 112 arranged therebetween. The recesses 111 start from an end of the retention rim 11 facing away from the end side 12 and extend in the direction of the end side 12 over more than 80% of the retention rim 11. The lamella portions 112 comprise an inner surface describing an inner surface of the retention rim 11 opposite to the outer surface 114. The inner surfaces of the lamella portions 112 are rounded outwardly towards the open end of the retention insert 1, i.e. towards the end of the retention insert 1 facing away from the end side 12, and thus compris...

second embodiment

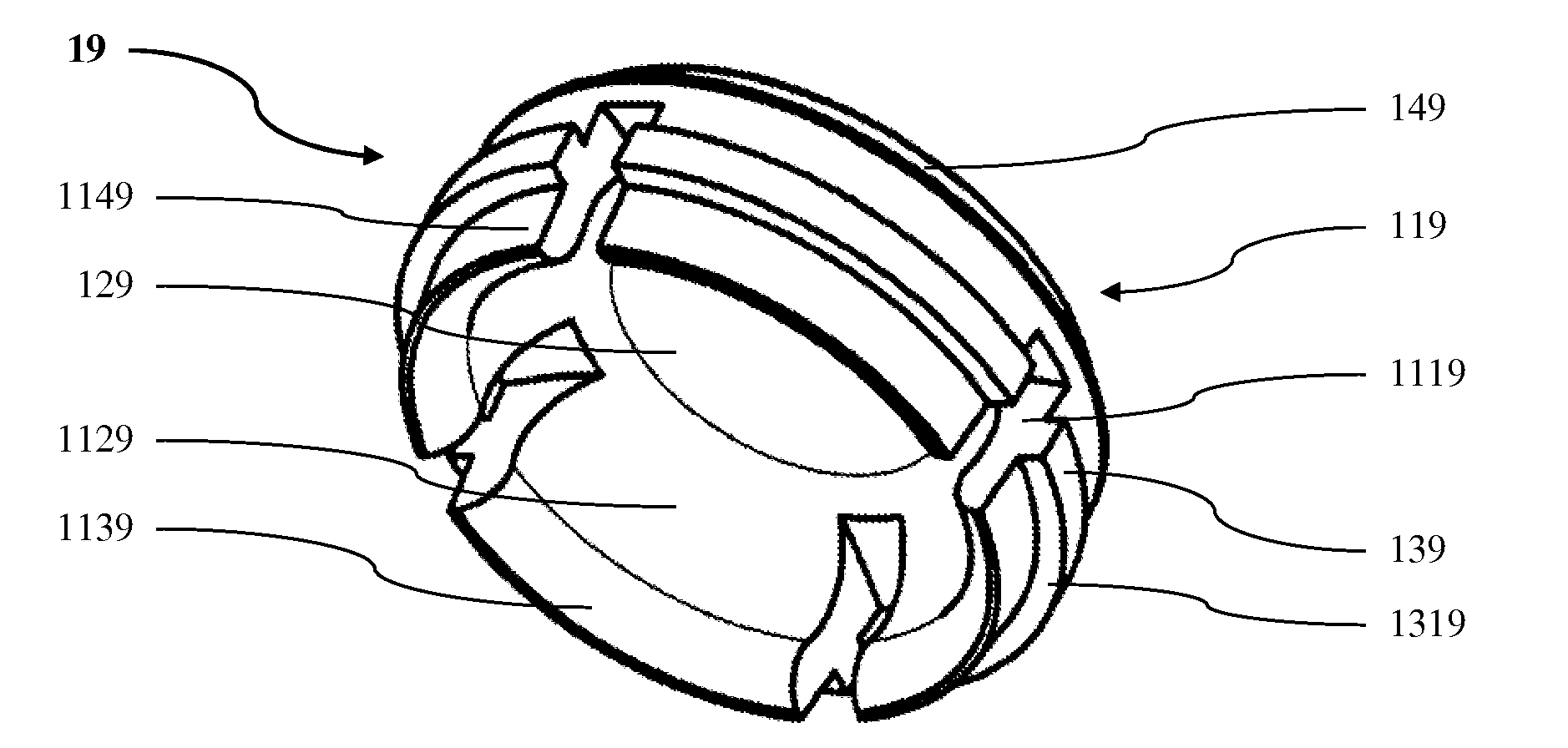

[0053]FIG. 8 shows a retention insert 19 according to the invention, which retention insert is designed substantially analogously to the retention insert 1 described above, except for the fact that it comprises a retention rim 119 having four recesses 1119. In particular, the retention insert 19 comprises an end side 129 as well as the retention rim 119 with an outer surface 1149, the four recesses 1119 spaced uniformly with respect to each other in the circumferential direction, as well as lamella portions 1129 arranged therebetween. The recesses 1119 are angled about 90° relative to each other. They start from an end of the retention rim 119 facing away from the end side 129 and extend in the direction of the end side 129 over more than 80% of the retention rim 119. The inner surfaces of the lamella portions 1129 have a curved portion 1139. The retention insert 19 further comprises a step 149 and a projection 139 having a projection supporting surface 1319. The retention insert 19...

third embodiment

[0054]FIG. 9 shows a retention insert 18 according to the invention, which retention insert is designed substantially analogously to the retention inserts 1 and 19 described above, except for the fact that it comprises a retention rim 118 having six recesses 1118. In particular, the retention insert 18 comprises an end side 128 as well as the retention rim 118 with an outer surface 1148, the six recesses 1118 spaced uniformly with respect to each other in the circumferential direction, as well as lamella portions 1128 arranged therebetween. The recesses 1118 are angled about 60° relative to each other. They start from an end of the retention rim 118 facing away from the end side 128 and extend in the direction of the end side 128 over more than 80% of the retention rim 118. The inner surfaces of the lamella portions 1128 have a curved portion 1138. The retention insert 18 further comprises a step 148 and a projection 138 having a projection supporting surface 1318. The retention ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com