Golf tee

a golf tee and tee body technology, applied in the field of golf tees, can solve the problems of easy breakage of golf tees, complicated assembly systems, and large consumption, and achieve the effects of easy cutting, strong strength, and improved elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

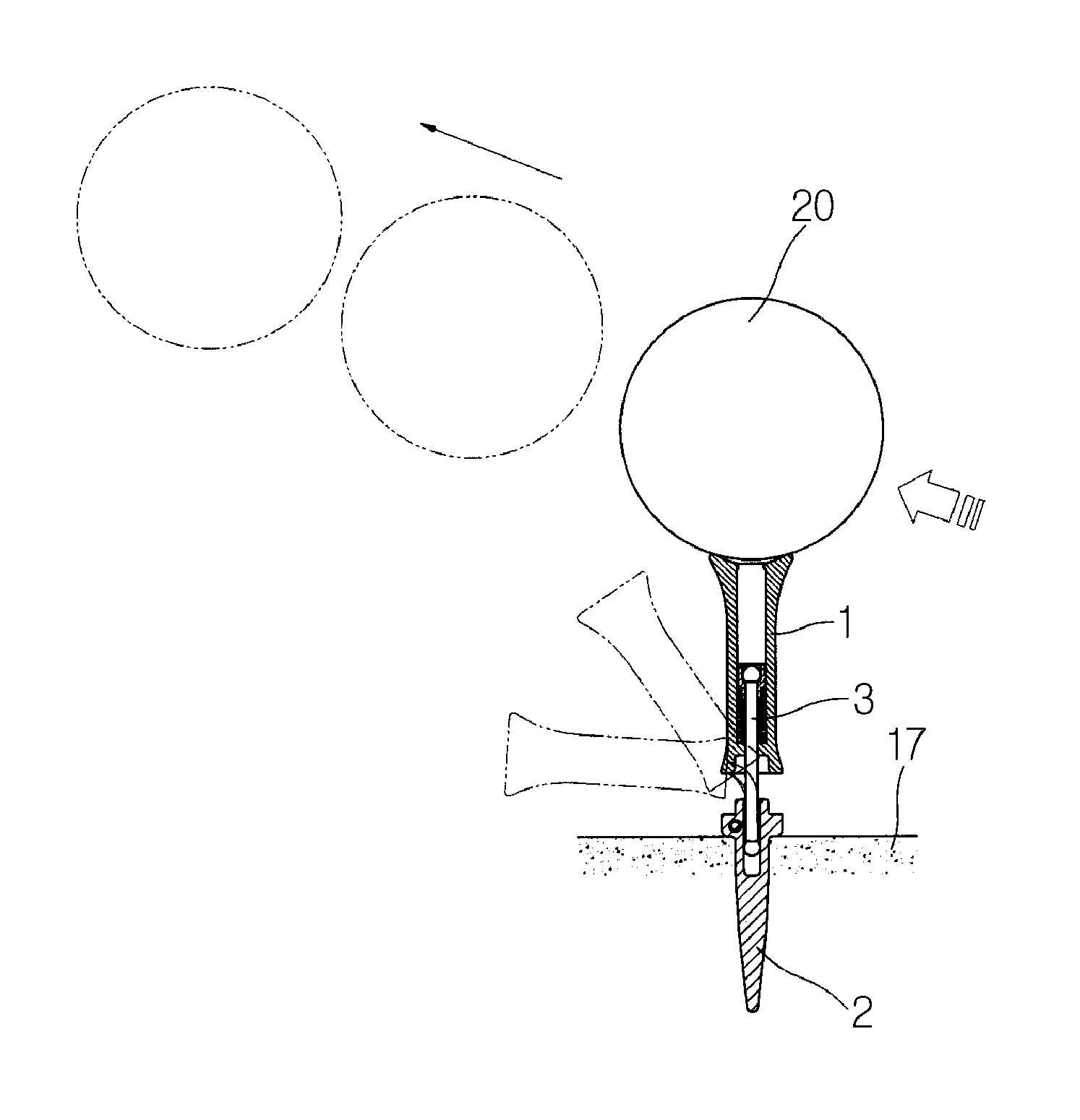

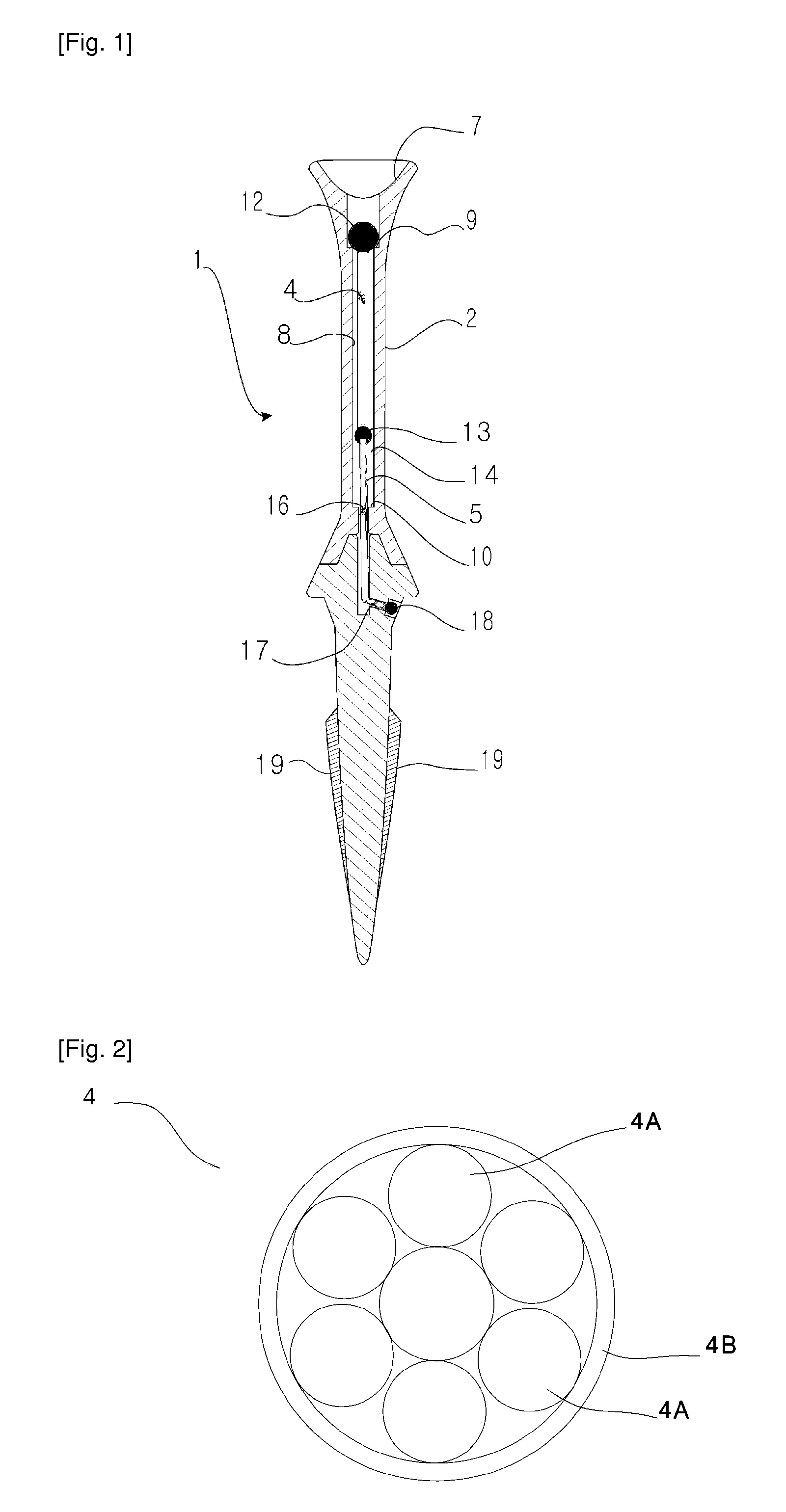

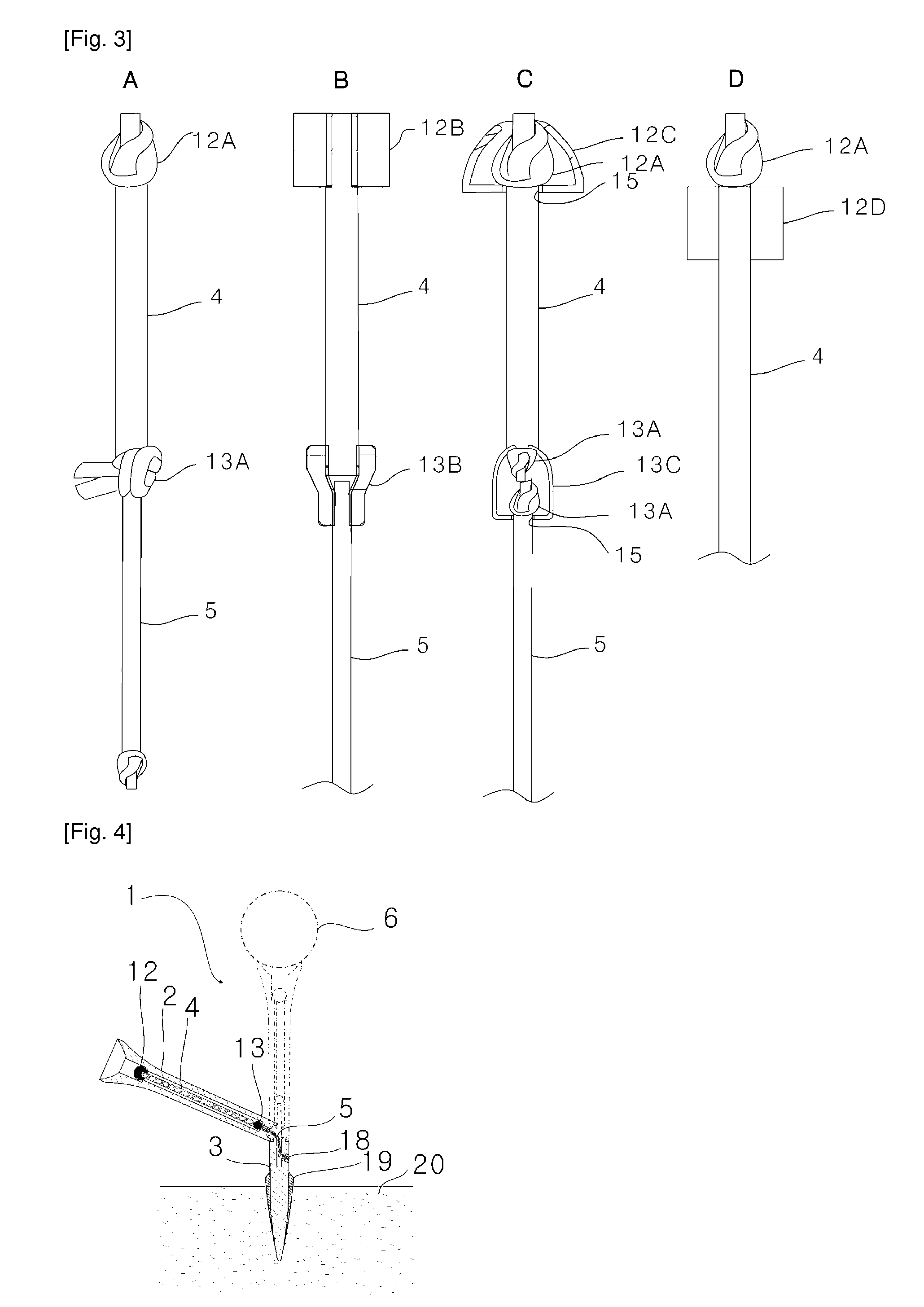

[0041]A golf tee comprises an upper member which includes a hollow portion formed in its inner side and passing through its upper side and lower side, a lower shoulder portion and a golf ball guide surface formed in its upper side; a lower member which supports the upper member while allowing the upper member from being bent when an impact force is applied to the upper member and is inserted in a ground when it is used; an upper engaging member which is caught by means of the upper shoulder portion; a lower engaging member which is caught by means of the lower shoulder portion wherein the lower engaging portion is spaced apart while leaving a move allowance space from the lower shoulder portion and is elastically elongated in a range of the move allowance space; an elastic member which is installed as having a tensional force; and a strong string of which upper end is engaged with the lower engaging portion, and lower end is tension-pulled and is extended toward the lower side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com