Sink drain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013]Embodiments of the present invention will now be described, by way of example only, with reference to the accompanying drawings.

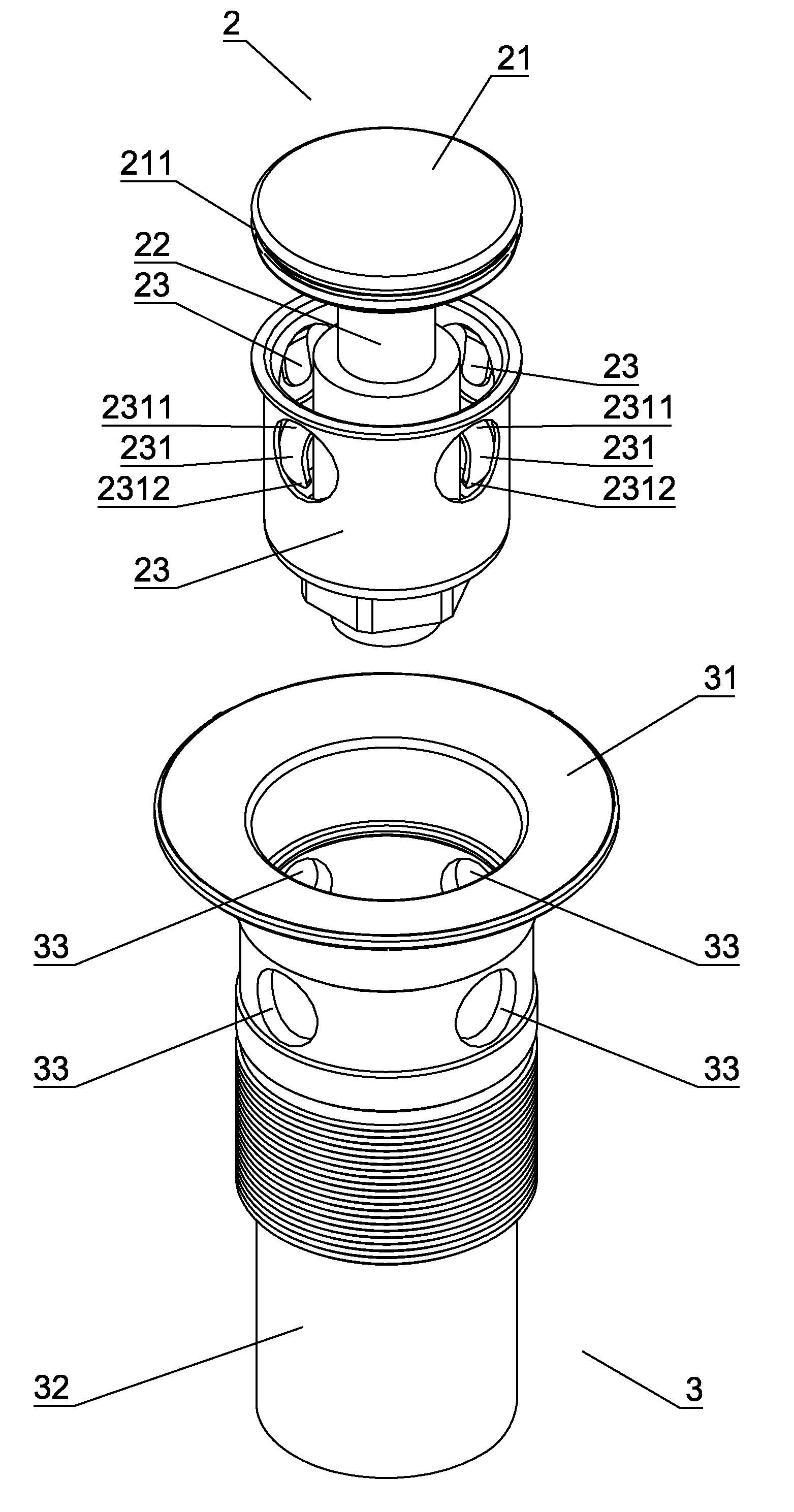

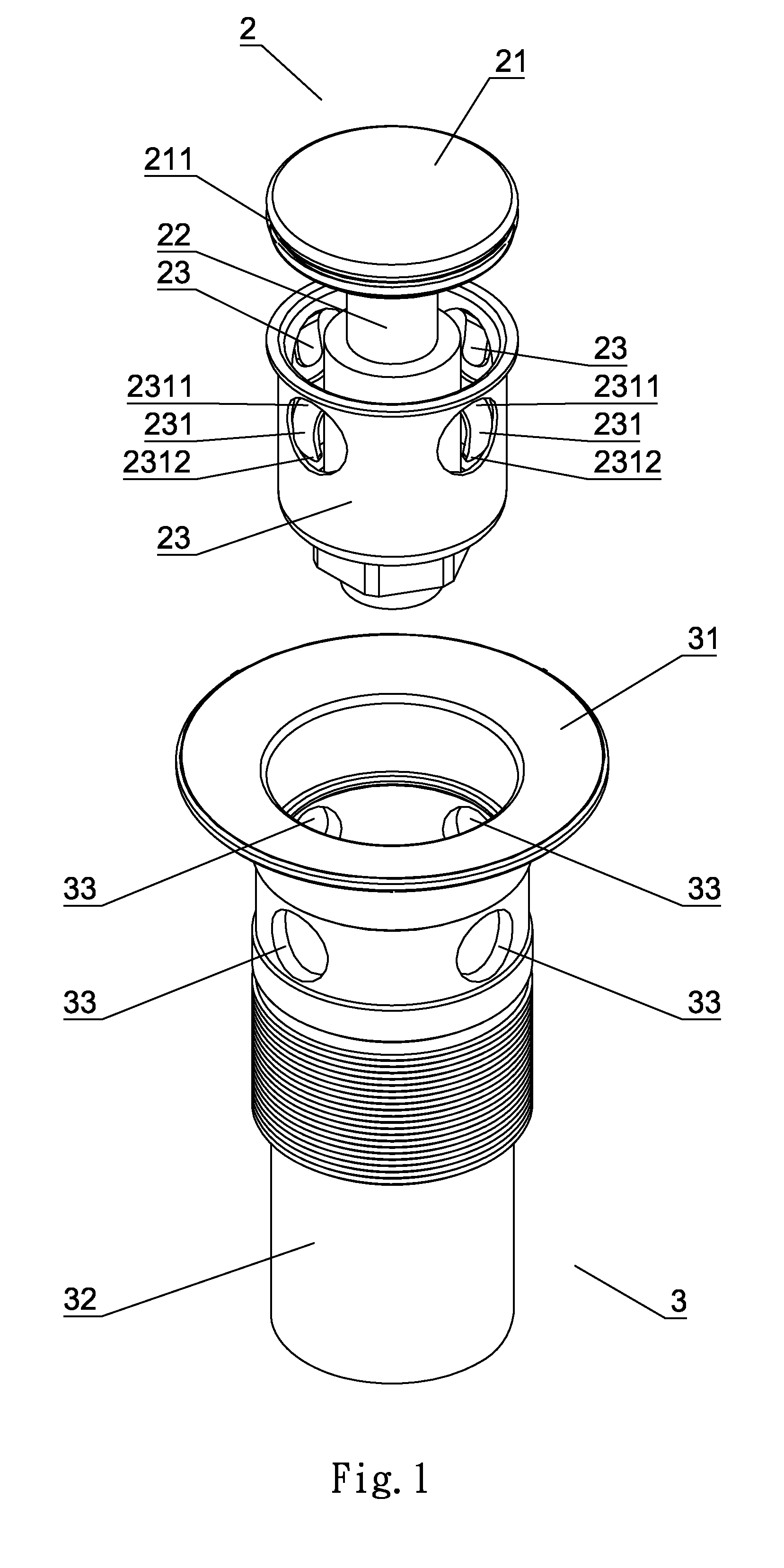

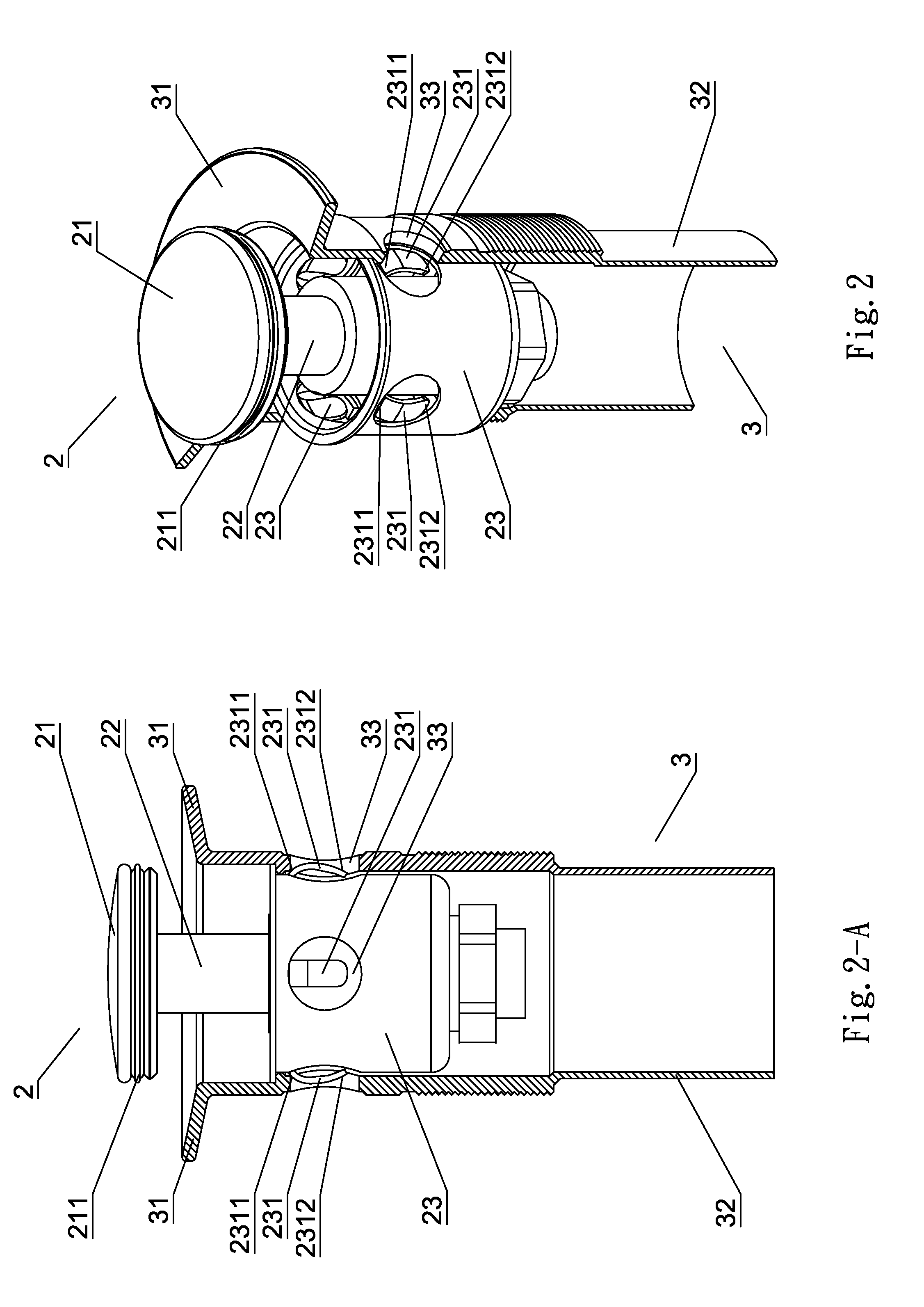

[0014]As shown in FIG. 1, FIG. 3 and FIG. 3-A, the sink drain according to a preferred embodiment of the present invention comprises an insertion cap 2 and a base 3.

[0015]The insertion cap 2 comprises an elastic telescopic pipe 22 and a stopper 21 disposed on top of the telescopic pipe 22. The stopper 22 is a flat plate with a washer 211 surrounding a peripheral edge thereof, and cooperates with the two-section telescopic pipe 22 to control drain of water. The insertion cap 2 further comprises a plug seat 23 which extends outward and upward from a bottom of the insertion cap 2 to form an opening facing up. At least one side of the plug seat 23 is provided with a protruding resilient plate 231. The resilient plate 231 is a curved plate which has an upper curve surface 2311 and a lower curve surface 2312.

[0016]The base 3 comprises a cylindrical body 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com