Blade sharpening device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

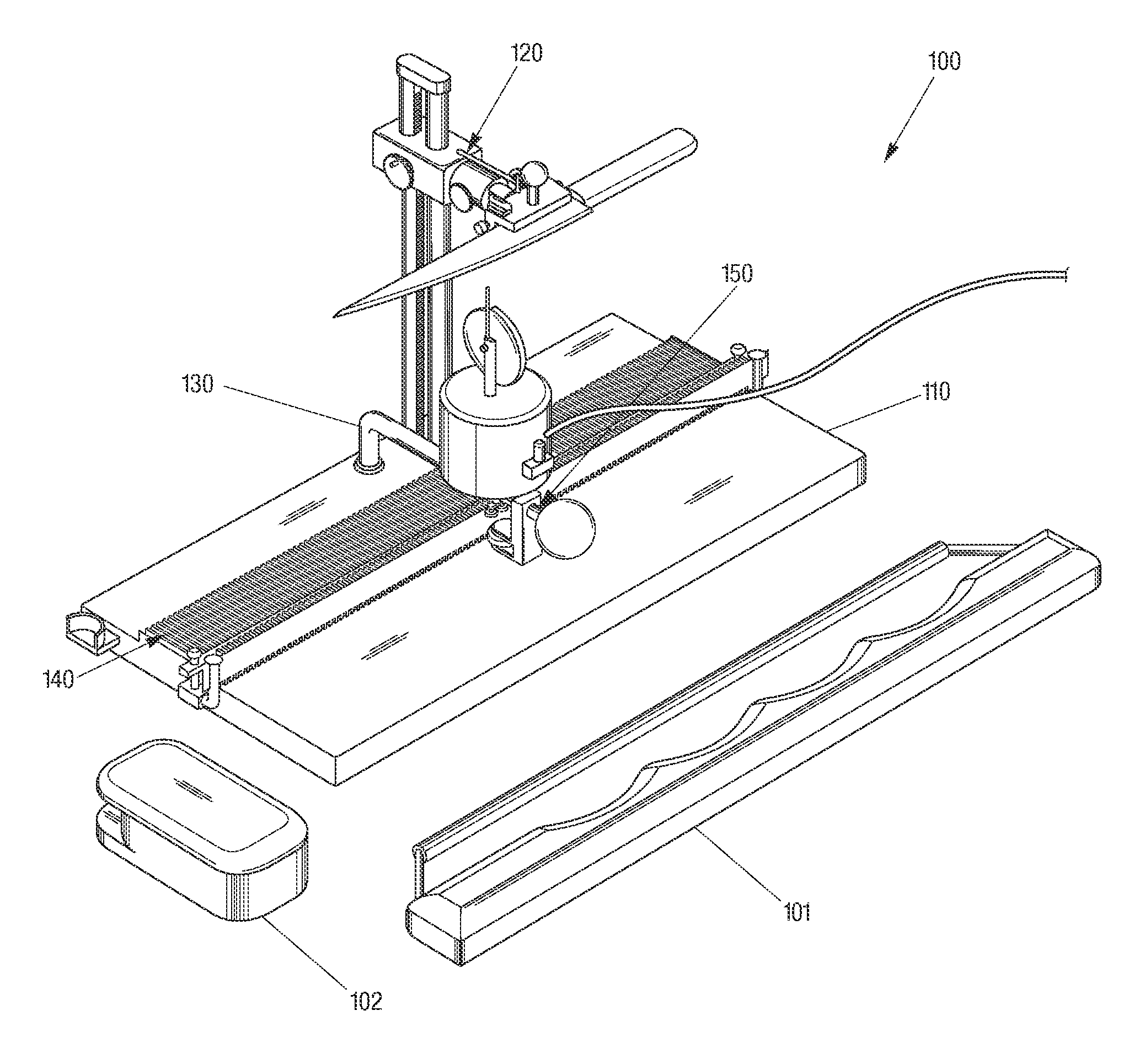

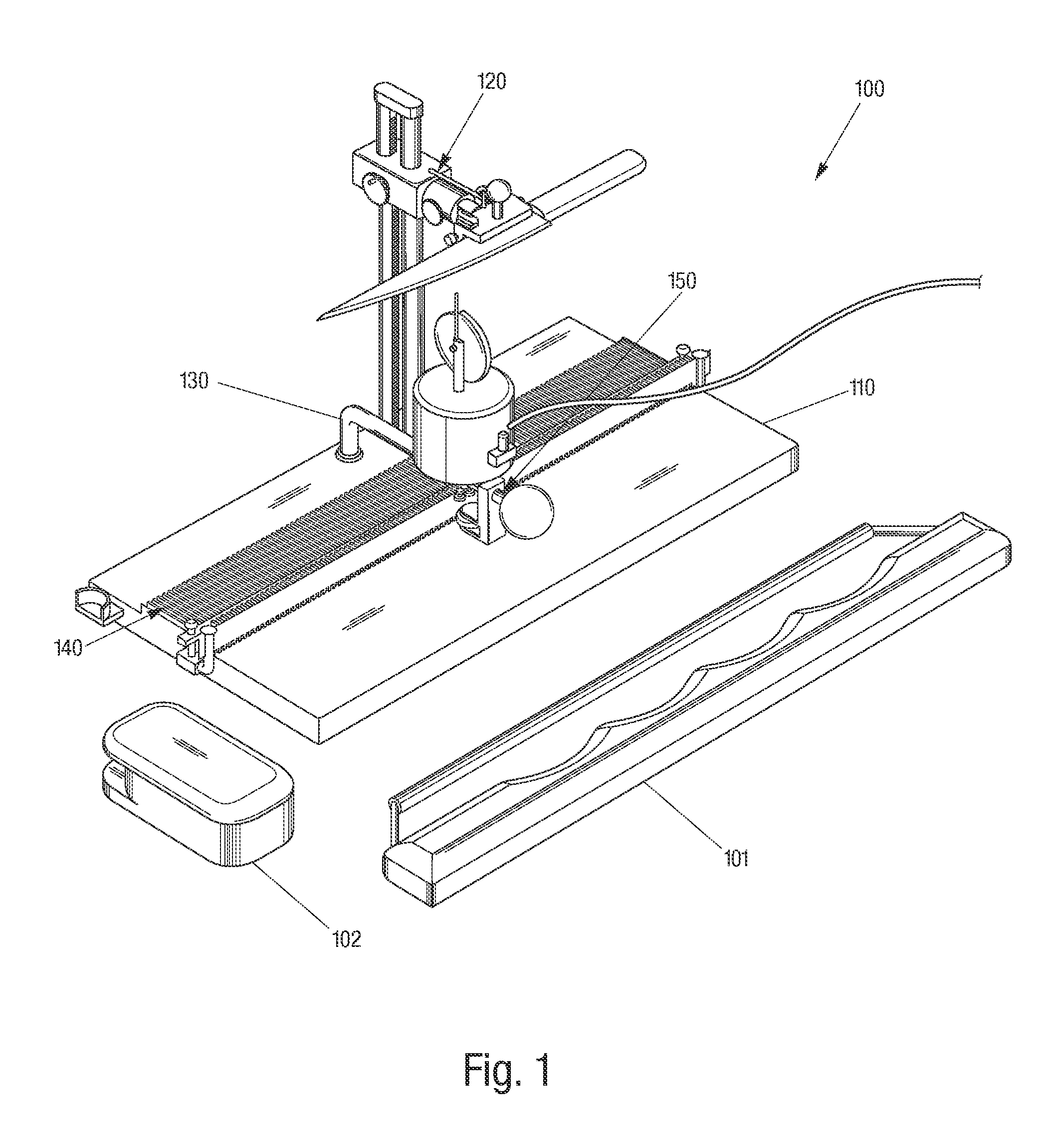

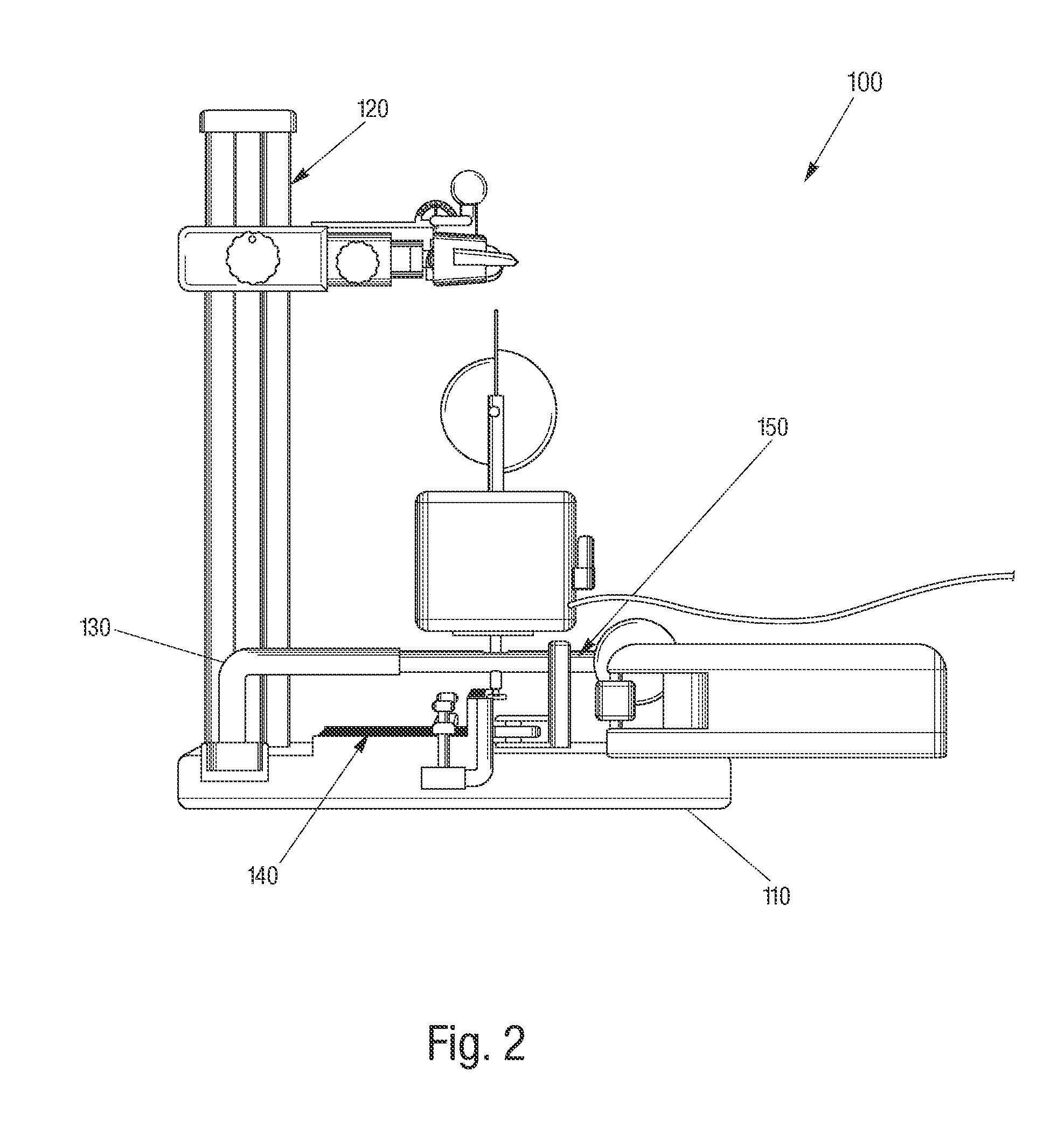

[0062]The present invention solves the problems in blade sharpening devices by providing a new and unique construction for consistent and effective sharpening of blades. Generally, the present invention is a blade sharpening device 100 designed for sharpening a blade for a uniform sharpening of the edge thereof. Most importantly, the present invention provides a sharpening path defined by a contour of the blade with minimal user input.

[0063]Now referring to FIGS. 1-10, the blade sharpening device 100 is designed for sharpening the blade for a uniform sharpening of the edge thereof. The present invention provides a blade sharpening device 100 designed for sharpening along the contour of the blade for a uniform sharpening of the edge thereof. The blade sharpening device 100 includes a base 110 that includes a material 140, such as tracers, that receive an impression of a blade defining a blade contour. A blade holder 120, using a height gauge, is attached to the base 110 for securing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Abrasive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com