Washing machine and control method thereof

a technology of washing machine and control method, which is applied in the direction of washing machine with receptacle, other washing machines, textiles and paper, etc., can solve the problems of ineffective removal of contaminants based on the chemical action of detergent, large amount of water consumed, and ineffective decomposition and removal of contaminants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Reference will now be made in detail to embodiments, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout.

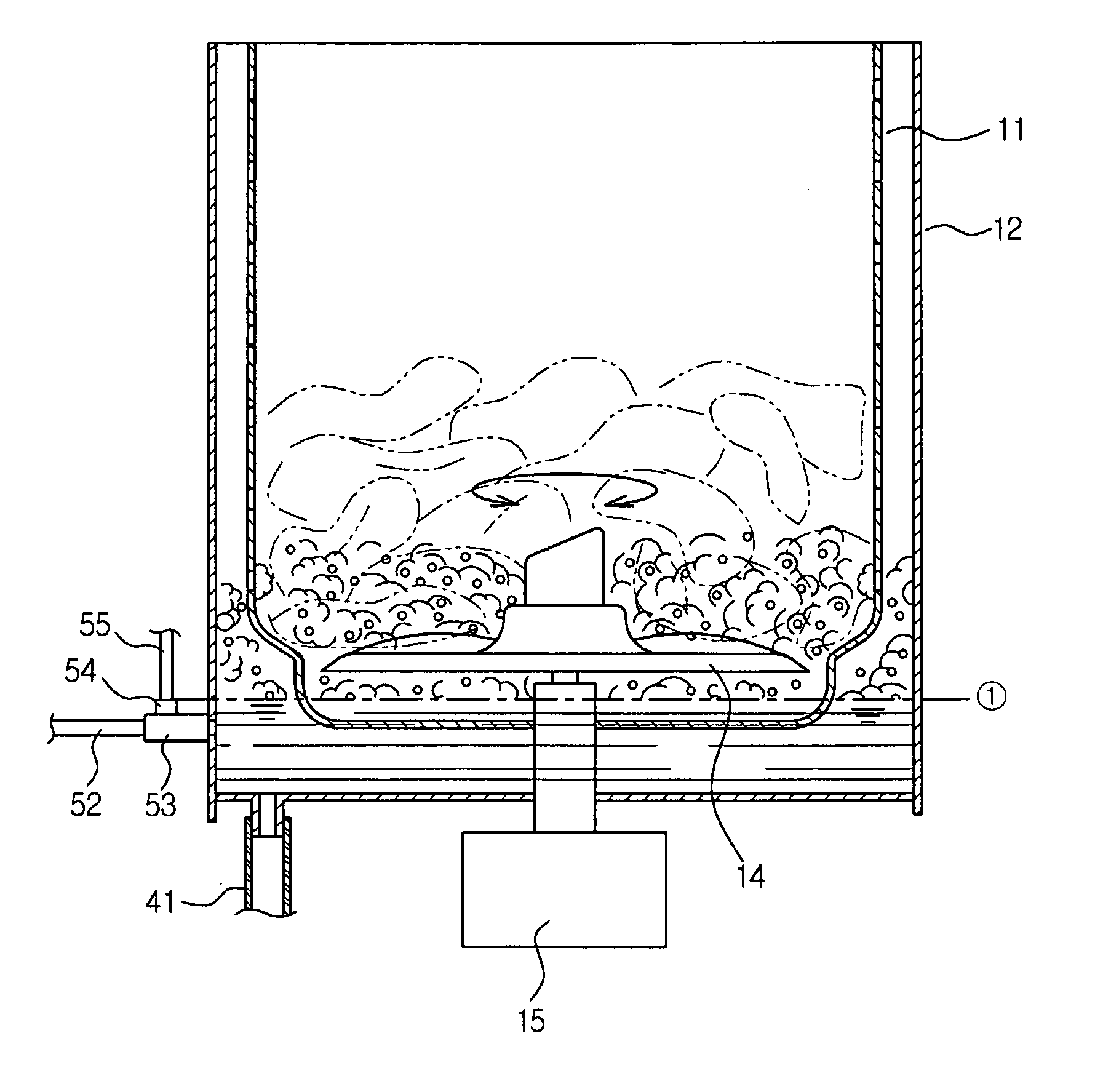

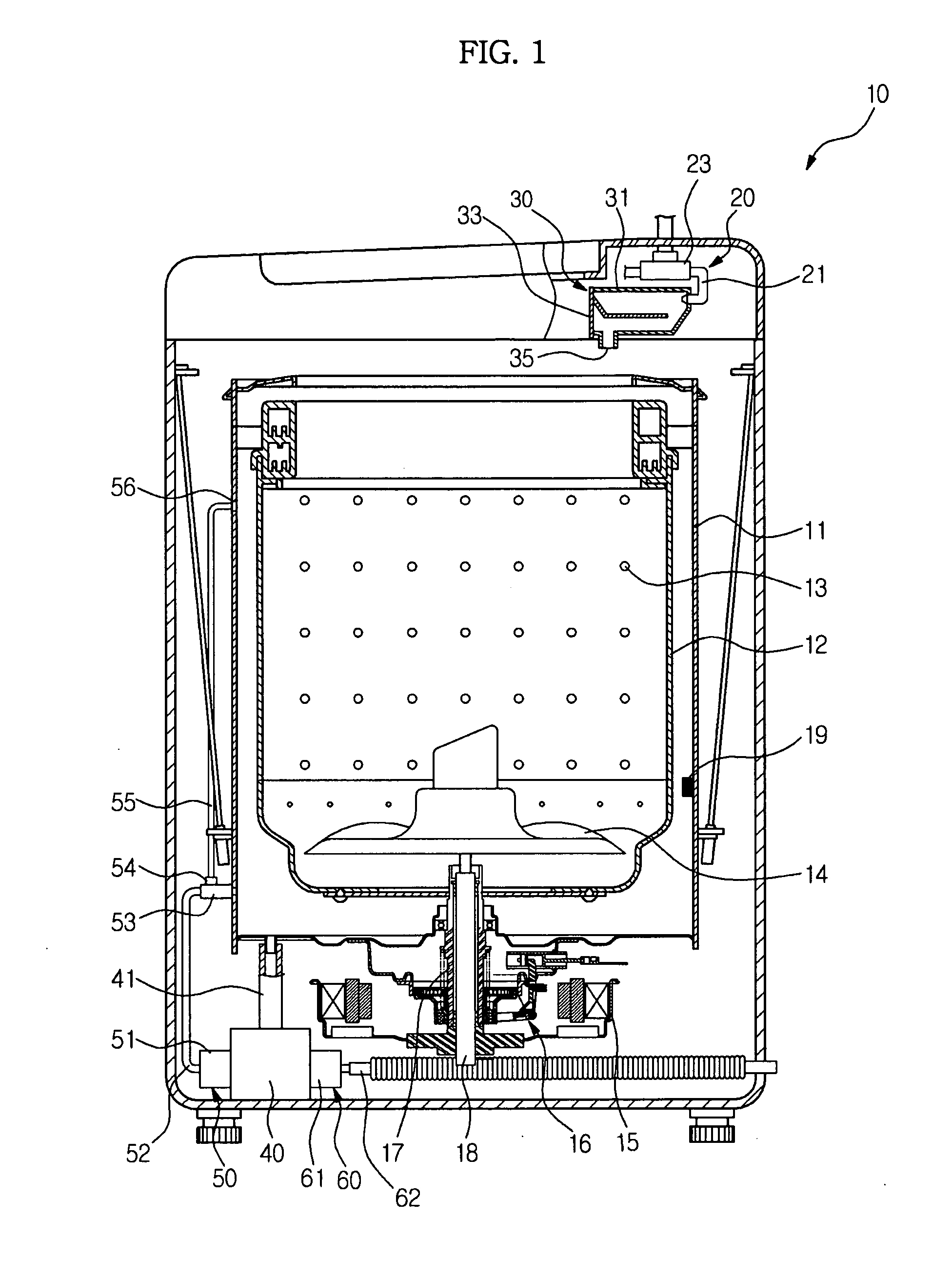

[0030]FIG. 1 is a sectional view illustrating a washing machine according to an embodiment.

[0031]As shown in FIG. 1, the washing machine includes a tub 11 mounted in a machine body 10 to contain water (wash water or rinse water) and a wash tub 12 rotatably mounted in the tub 11 to contain laundry. The wash tub 12 has a plurality of holes 13. A pulsator 14 is rotatably mounted in the wash tub 12. The pulsator 14 rotates clockwise or counterclockwise to generate a water current.

[0032]At the outside bottom of the tub 11 are mounted a motor 15 to generate drive force to rotate the wash tub 12 and the pulsator 14 and a power transmission device 16 to simultaneously or selectively transmit the drive force from the motor 15 to the wash tub 12 and the pulsator 14.

[0033]The motor 15 is a direct drive type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com