Roofing system and self-bridging tape for modular building construction roof joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

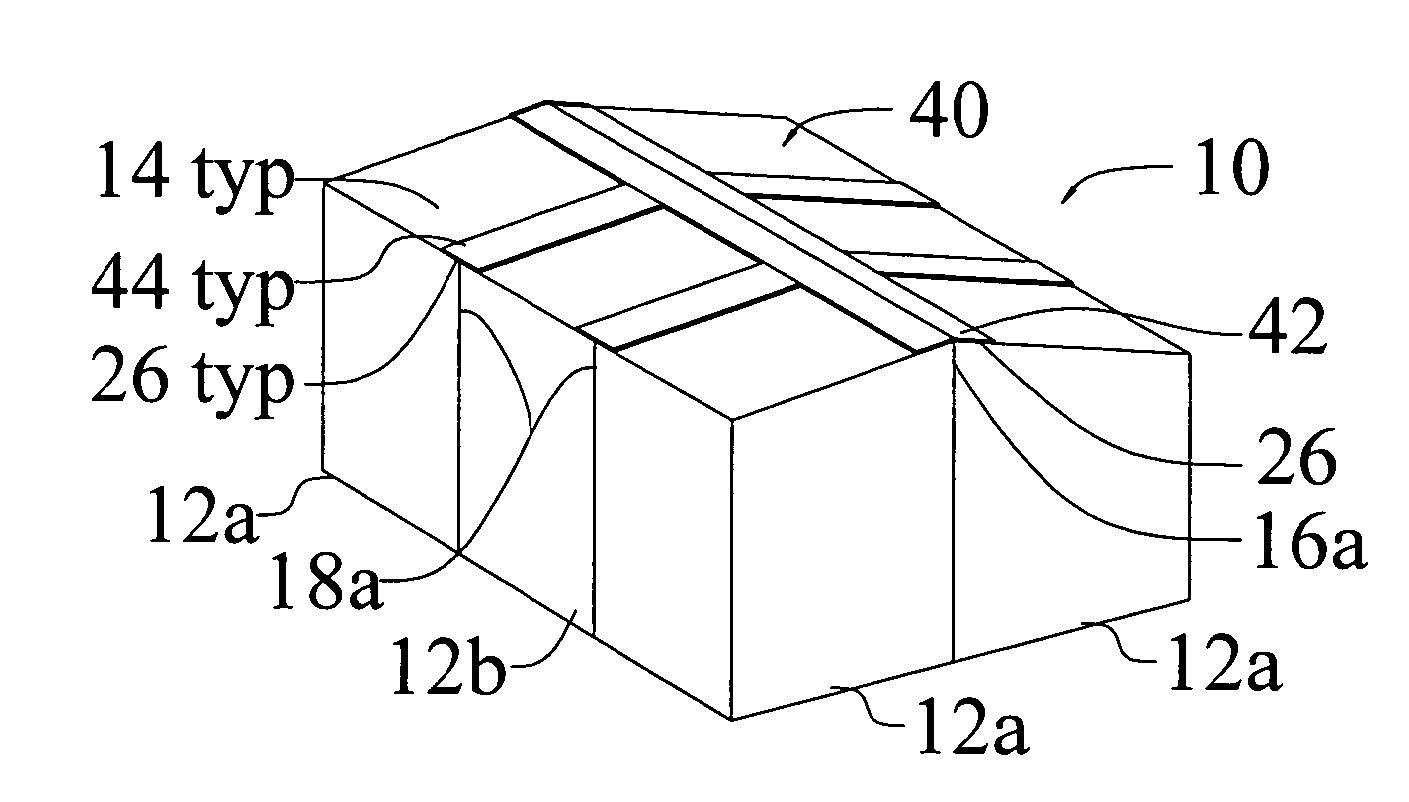

[0060]The present invention relates to a membrane roofing system for modular buildings, such as building 10 shown in FIG. 1, and to a laminate tape for sealing joints between the membrane roofing sheets of adjacent building modules such as modules 12a and 12b shown. For illustration purposes, the membrane roofing sheets 14 shown in the drawings terminate at the edges of the building modules 12a, 12b. However, the membrane roofing sheets are more typically provided folded over the edges of the modules, with a terminating strip securing the ends of the membrane to the sides of the modules.

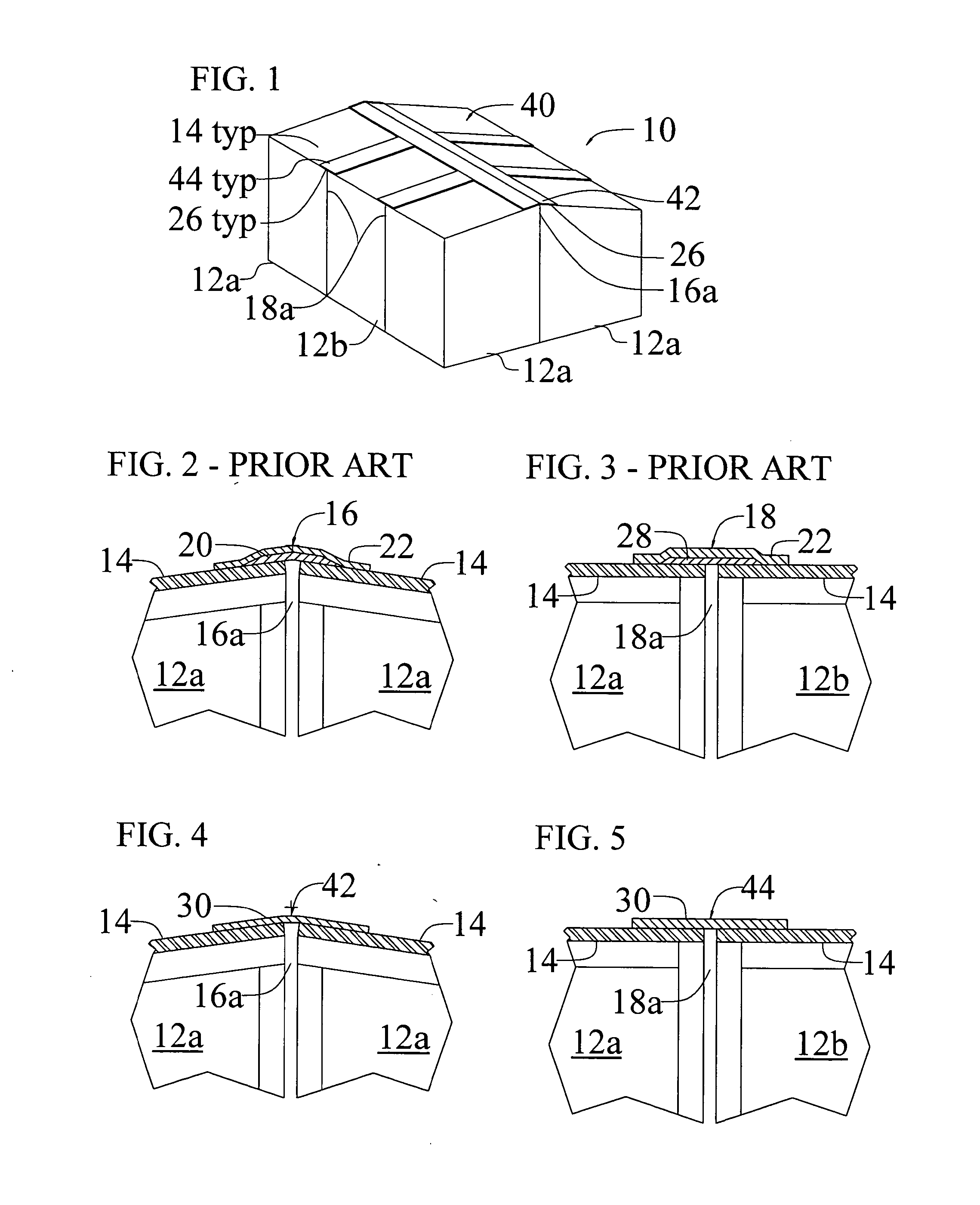

[0061]One prior technique for establishing a roofing joint between the membrane sheets of adjacent building modules is shown in FIG. 2 in connection with sealing the roof joint 16a between mirrored adjacent building modules 12a, and in FIG. 3 in connection with sealing roof joint 18a between side-by-side modules 12a and 12b. Briefly, the seal joint 16 (FIG. 2) is established by securing an elongated,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com