Can-based system to calculate the weight of milled materials

a can-based system and milled material technology, applied in the direction of roads, instruments, roads, etc., can solve the problems of excessively heavy dump trucks, unsafe roadways, and inability to properly weigh milled materials,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

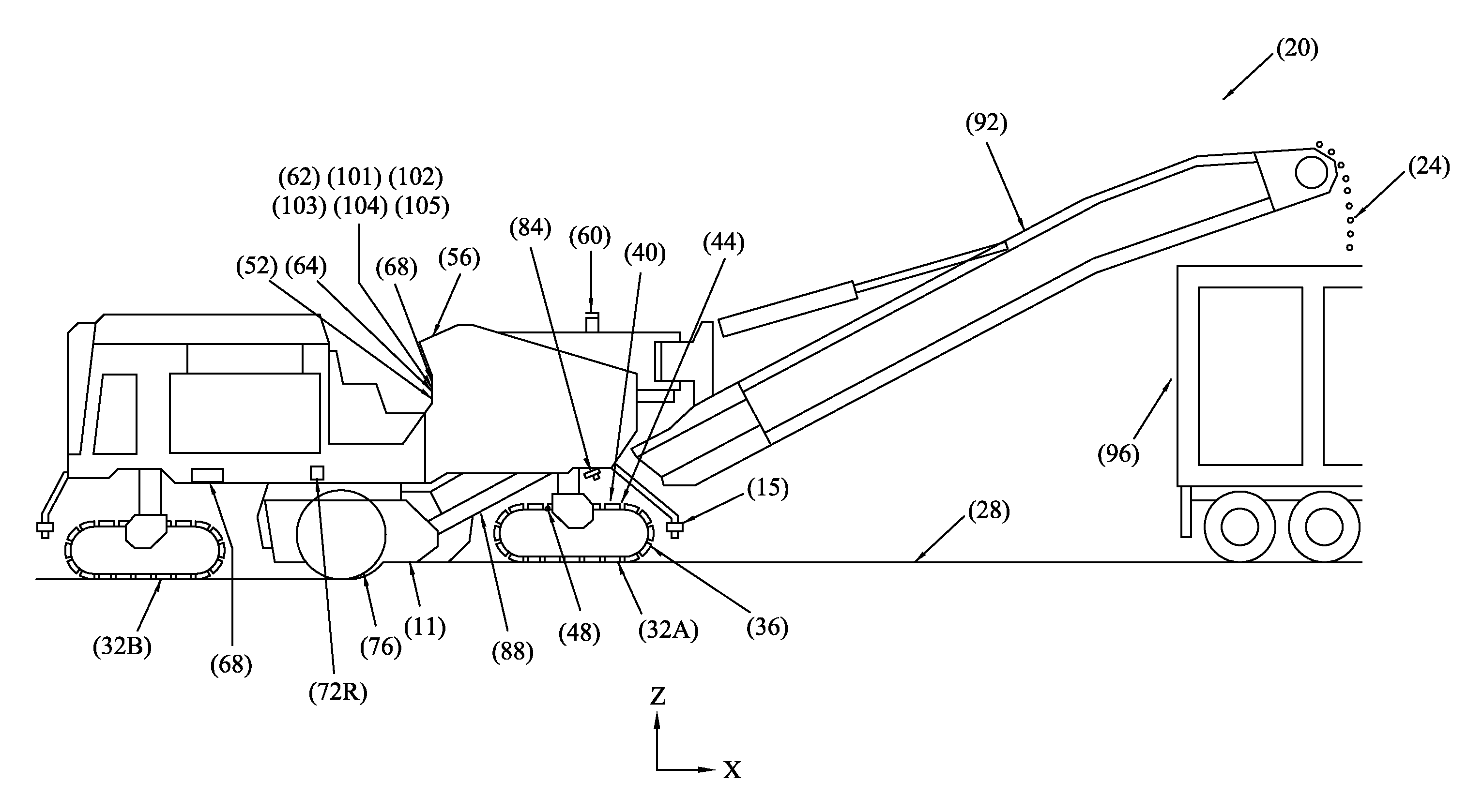

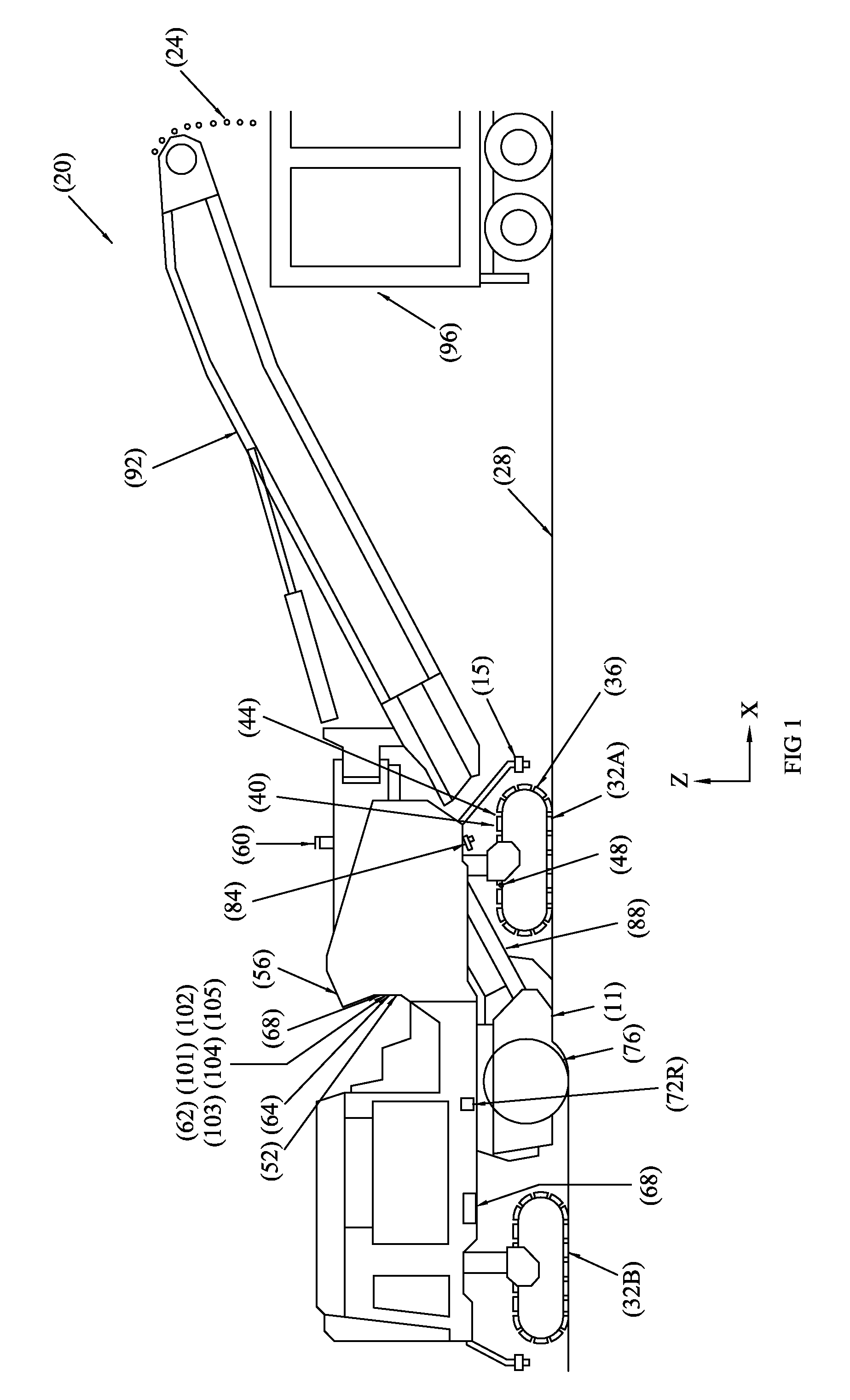

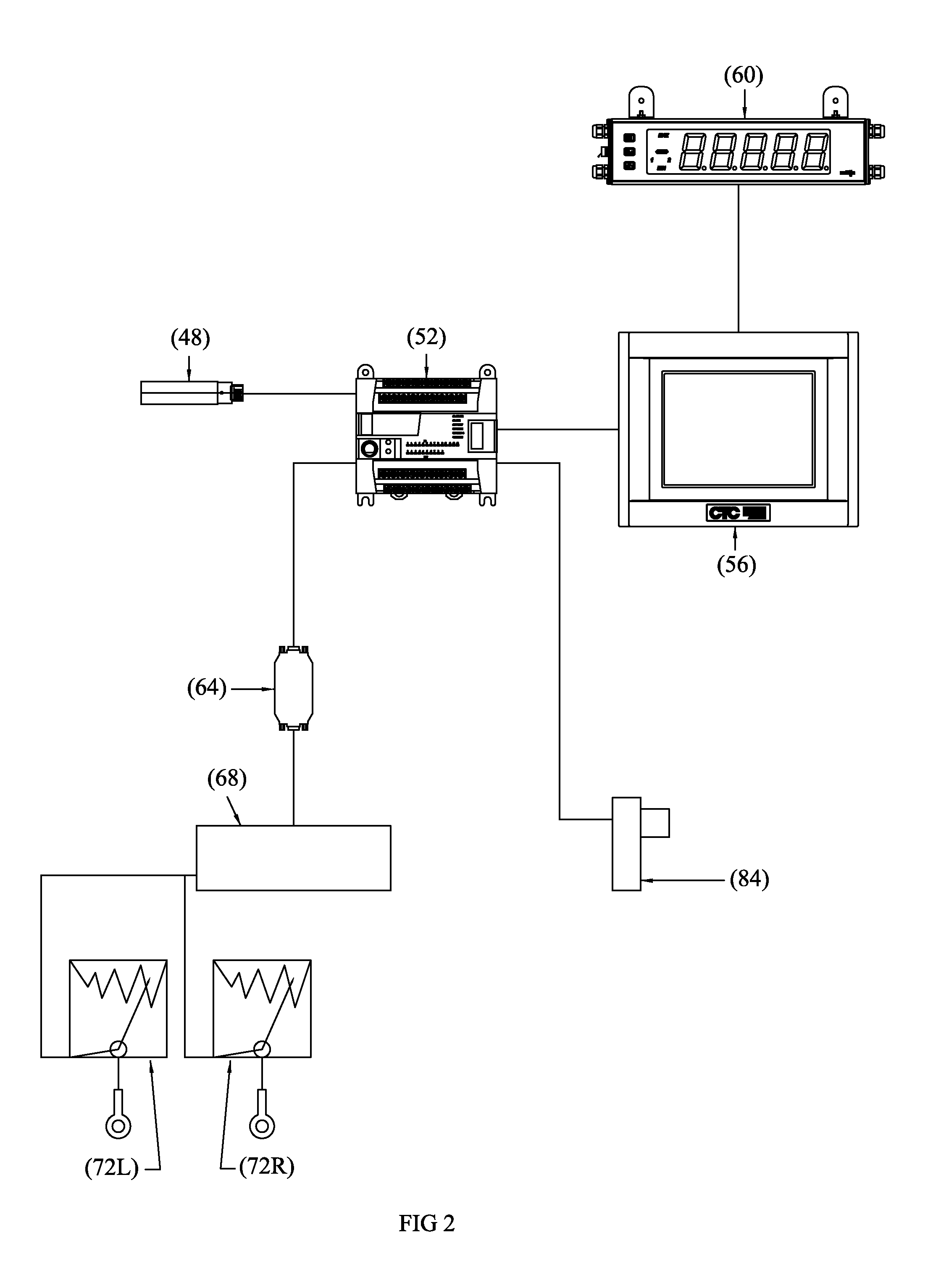

[0013]Preliminarily, it should be noted that certain terms which may be used herein, such as for example above, below, upper, lower, left and right, are used to facilitate the description of the invention. Unless otherwise specified or made apparent by the context of the discussion, such terms and other directional terms should be interpreted with reference to the figure(s) under discussion. Such terms are not intended as limitations on the position in which the invention or components may be used. Indeed, it is contemplated that the components of the invention may be easily positioned in any desired orientation for use. Likewise, numerical terms such as for example “first”, and “second” are not intended as a limitation or to imply a sequence, unless otherwise specified or made apparent by the context of the discussion. The term “operatively connected” is understood to include a linking together of the portions under consideration and may include a physical engagement and / or a funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com