Storing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The invention will now be described in more detail by means of an example and with reference to the accompanying drawings.

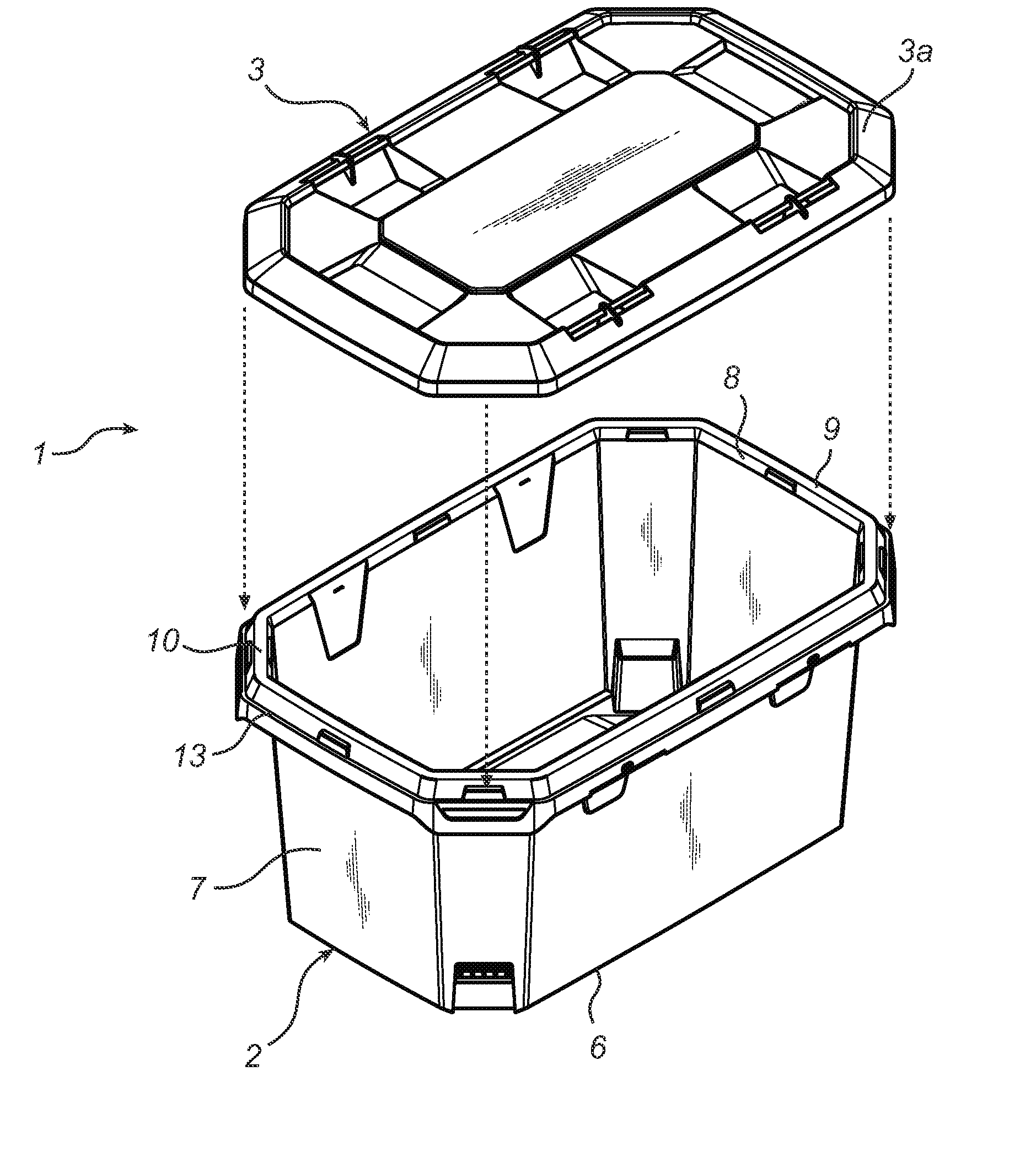

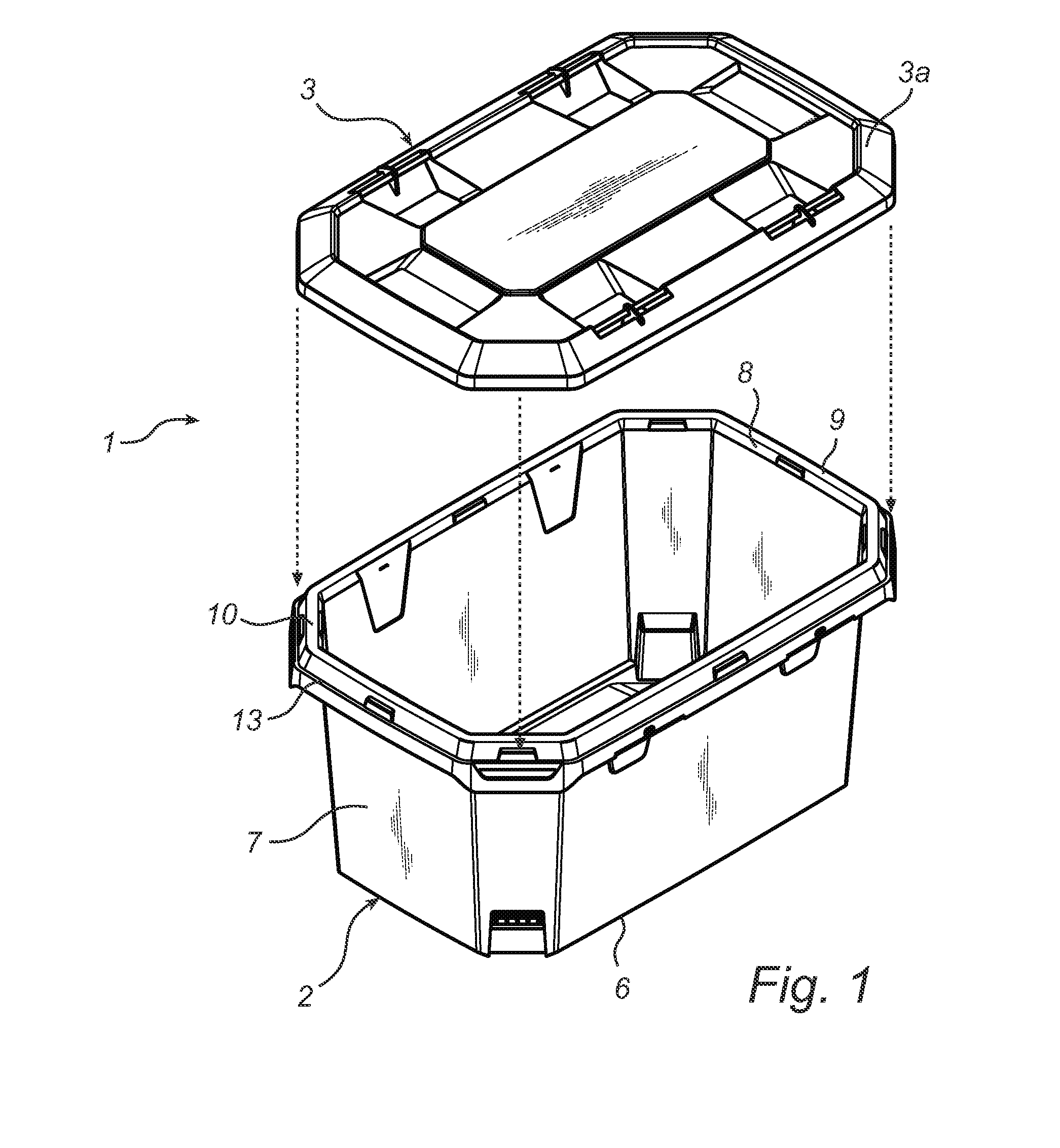

[0021]FIG. 1 shows a storing device 1 representing an embodiment of the invention. The storing device 1 includes a storage box 2 and a lid 3 made of a plastic material such as polypropene. The box 2 has a basically rectangular bottom 6 and a four-sided circumferential wall 7. The corners of the box 2 are cut, making the geometrical shape of the box 2 really eight-sided. The upper portion 8 of the circumferential box wall 7 is formed by a rather rounded fold which is adapted for fitting into a peripheral hollow elevation 3a of the lid 3.

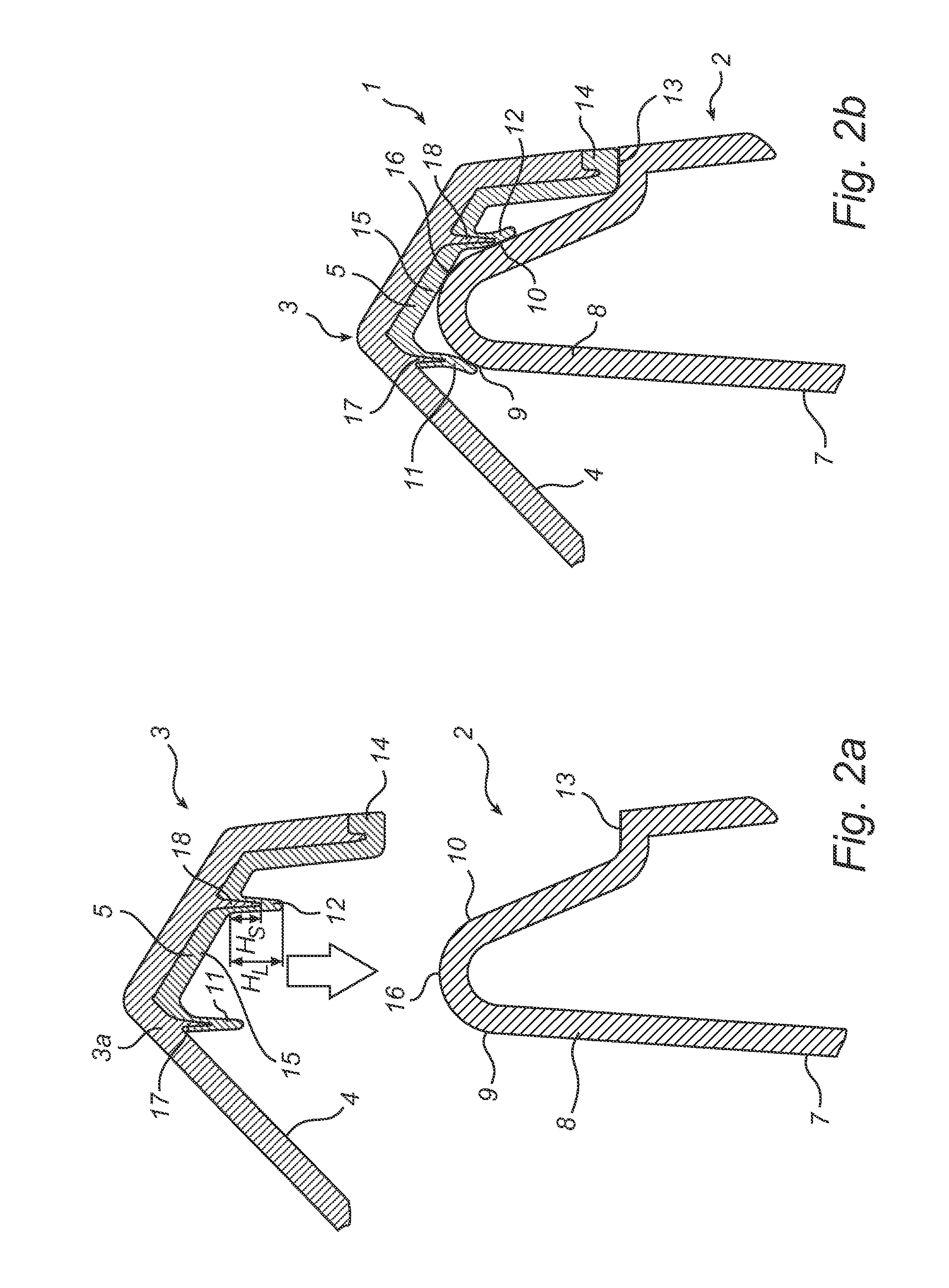

[0022]FIG. 2a shows an embodiment of the storing device 1 in an open position, where the lid 3 is about to be put onto the box 2, and FIG. 2b shows the storing device 1 in a closed, sealed position.

[0023]A rubber sealing ring 5 may be attached inside the hollow elevation 3a, on the underside 4 of the lid 3, to enhance the tig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com