Smoke and clean air generating machine for detecting the presence and location of leaks in a fluid system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

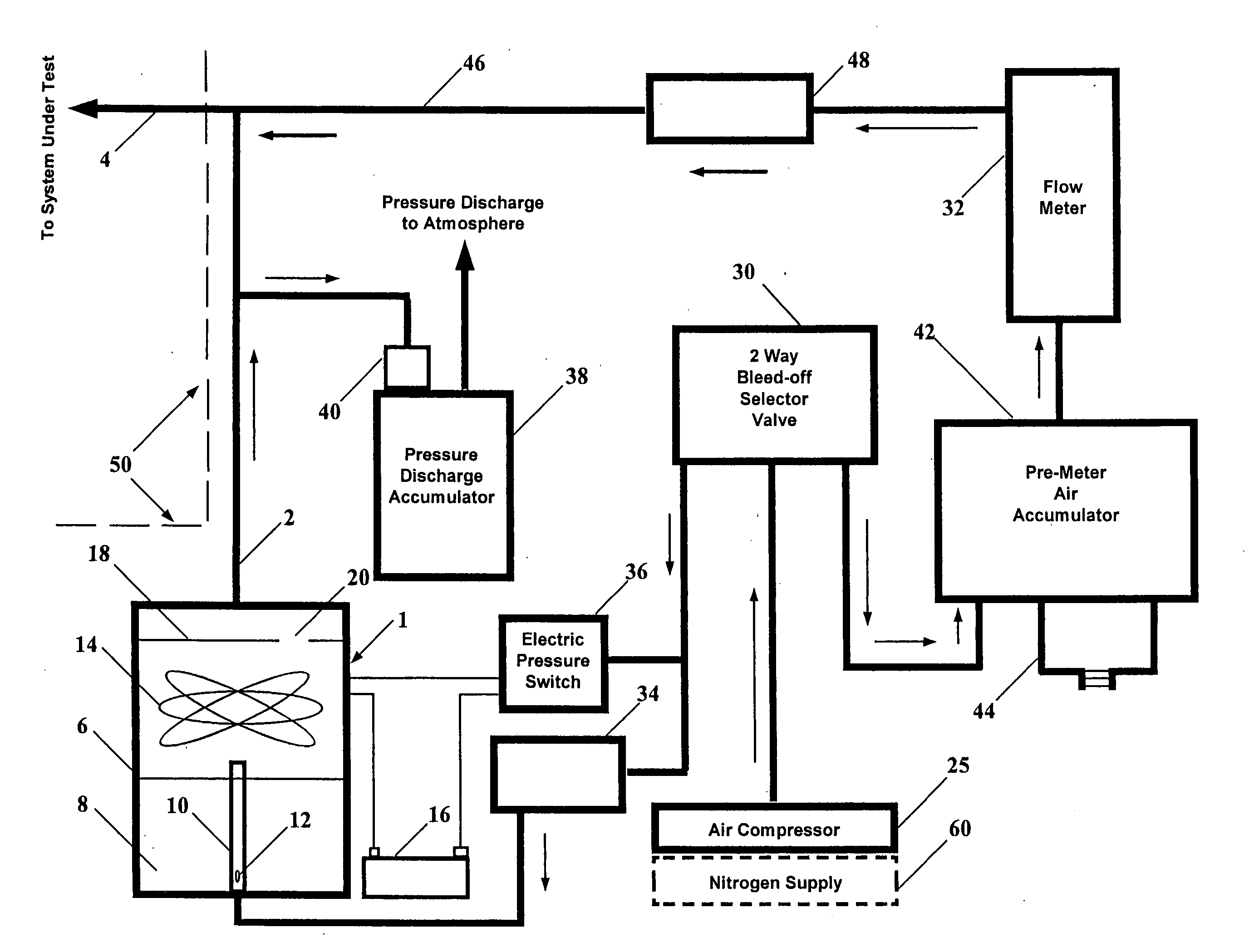

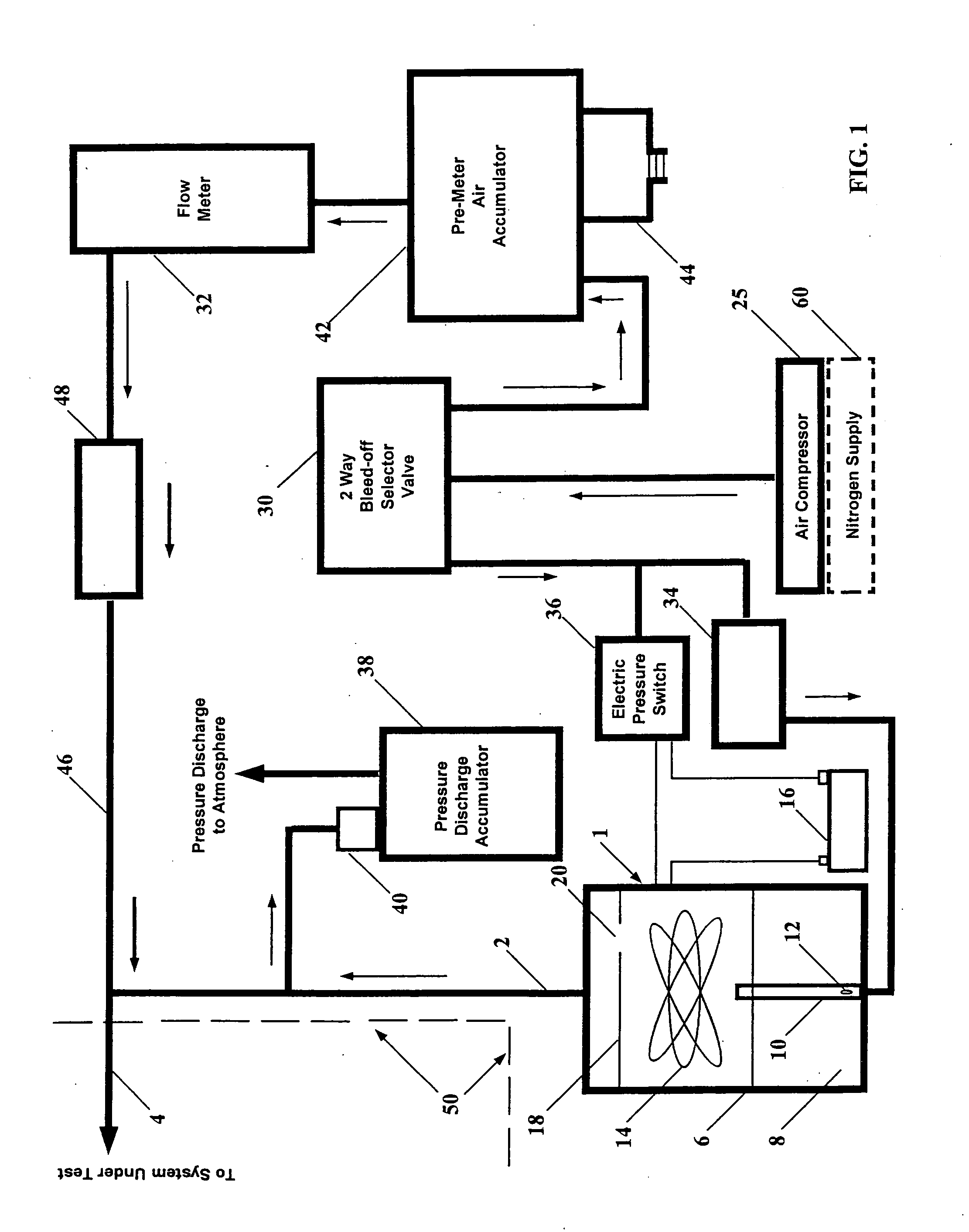

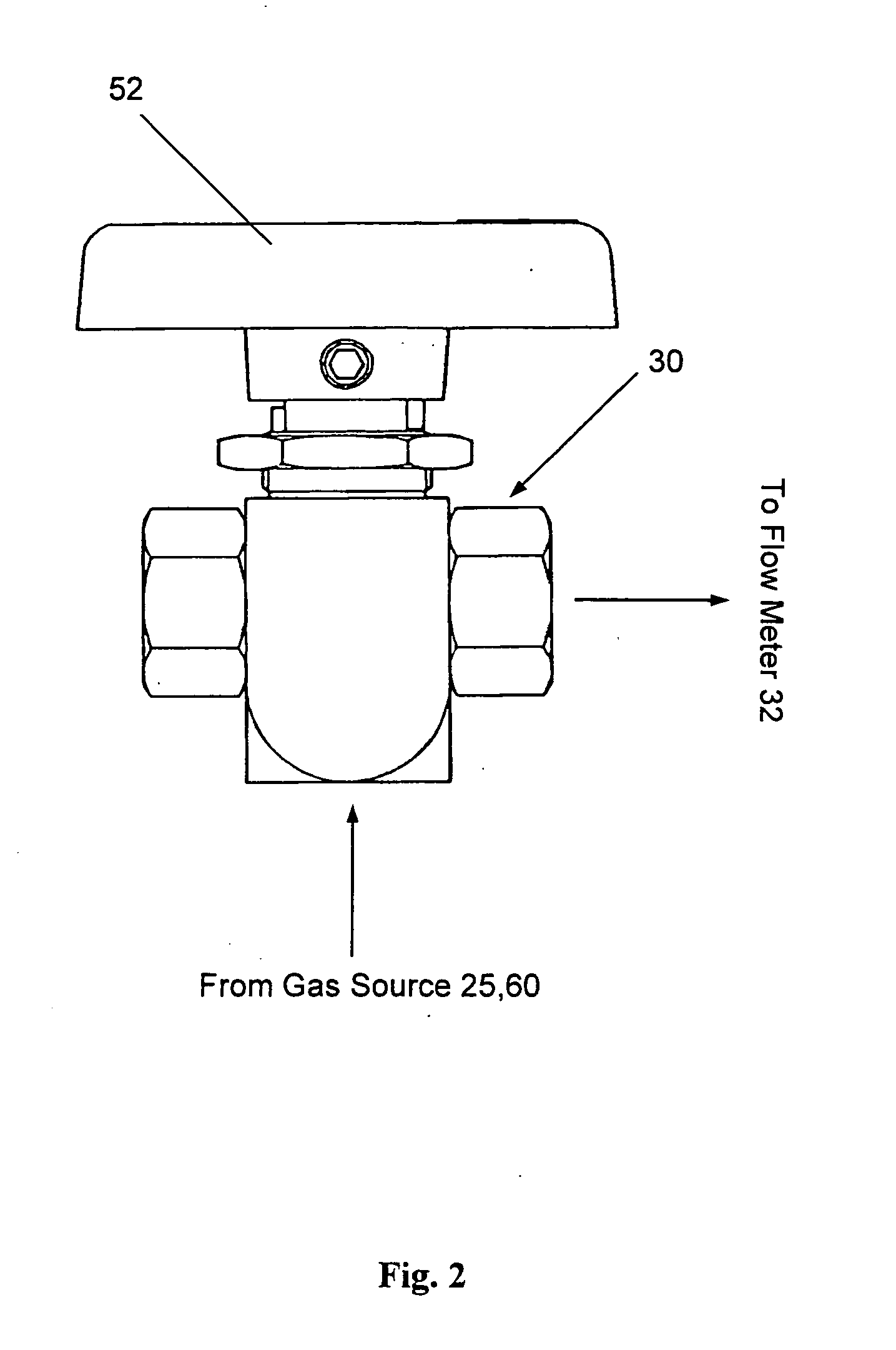

[0015] Referring to the drawings, there is shown in FIG. 1 a smoke and clean air generating machine having an outer casing (designated by phantom lines) 50 within which is housed a smoke generating apparatus 1 that is adapted to generate a supply of smoke to a smoke outlet line 2 and a smoke supply line 4 so that a fluid system (not shown) can be visually inspected for leaks. The smoke generating apparatus 1 has been described in detail in our earlier patent application Ser. No. 09 / 020,841 filed Feb. 9, 1998, the teachings of which are incorporated herein by reference. Therefore, a full description of the smoke generating apparatus 1 will not be provided.

[0016] Briefly, however, the smoke generating apparatus 1 includes a sealed chamber 6 which contains a non-toxic oil supply 8. An air inlet tube 10 projects upwardly from the bottom of chamber 6 and extends above the oil supply 8. Inlet tube 10 communicates with an external air compressor 25 through a wall of chamber 6. An inlet or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com