Suture system

a suture system and valve technology, applied in the field of suture systems, can solve the problems of suture breakage, poor valve seating, peri-valvular leakage,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

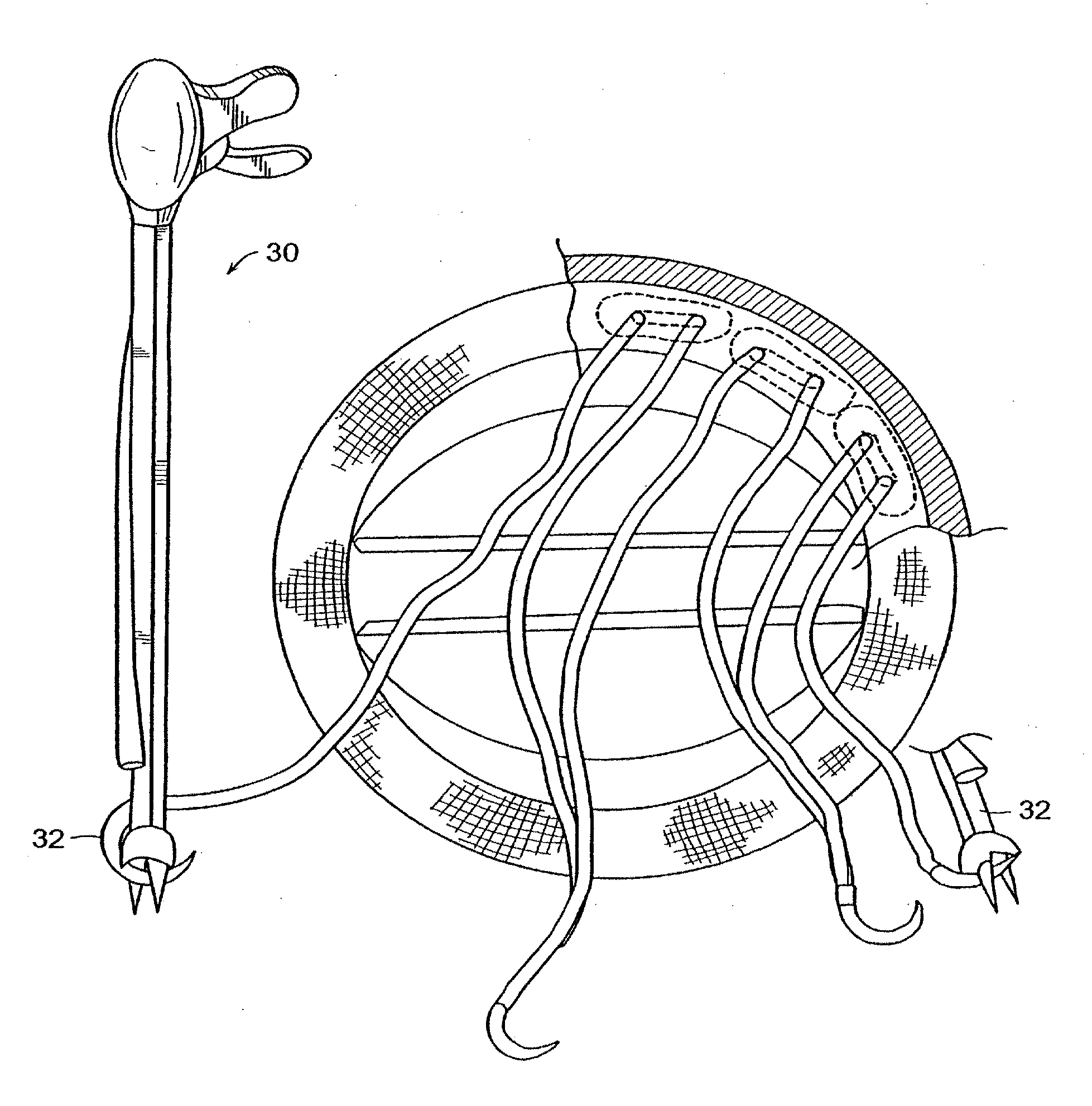

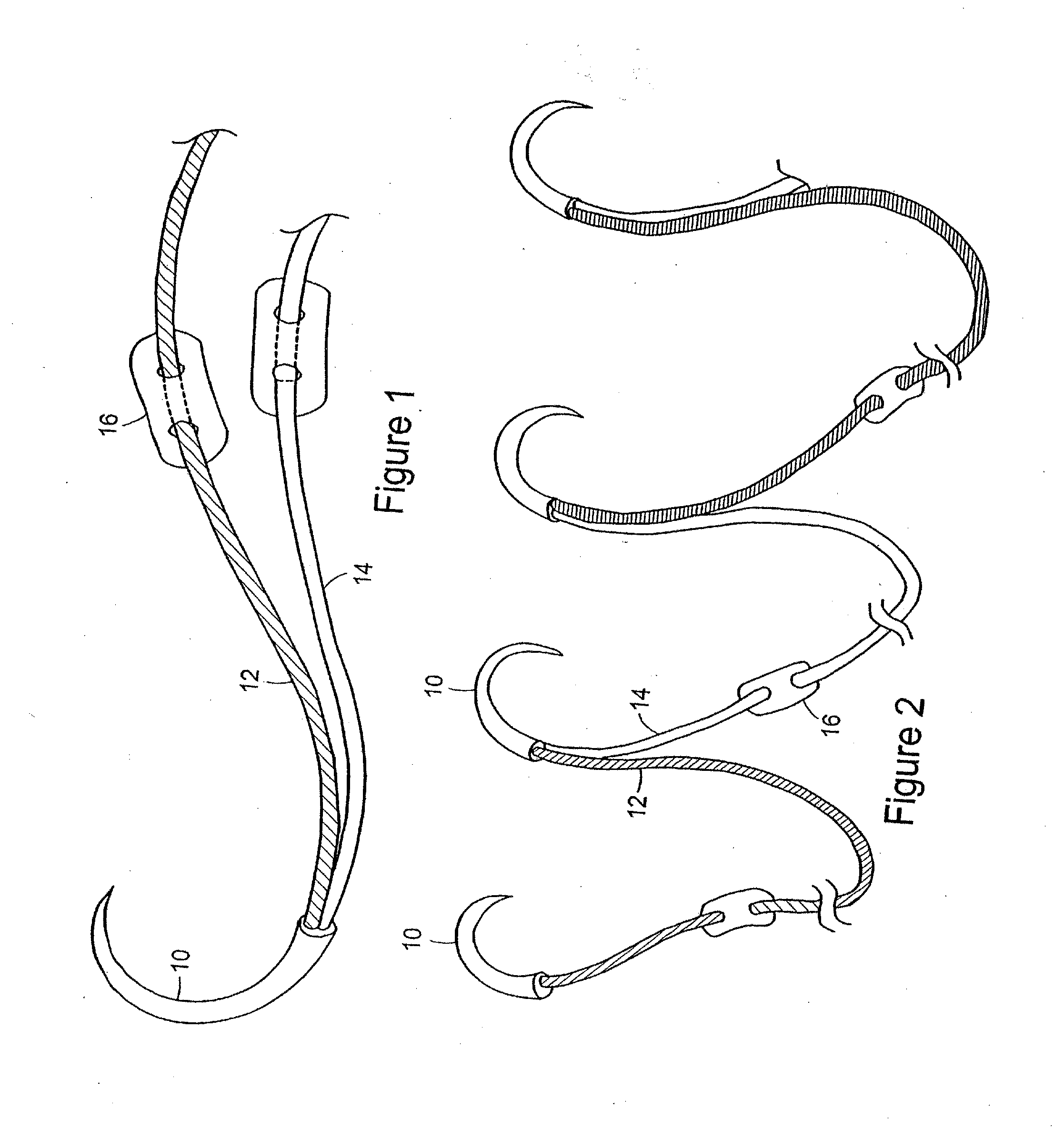

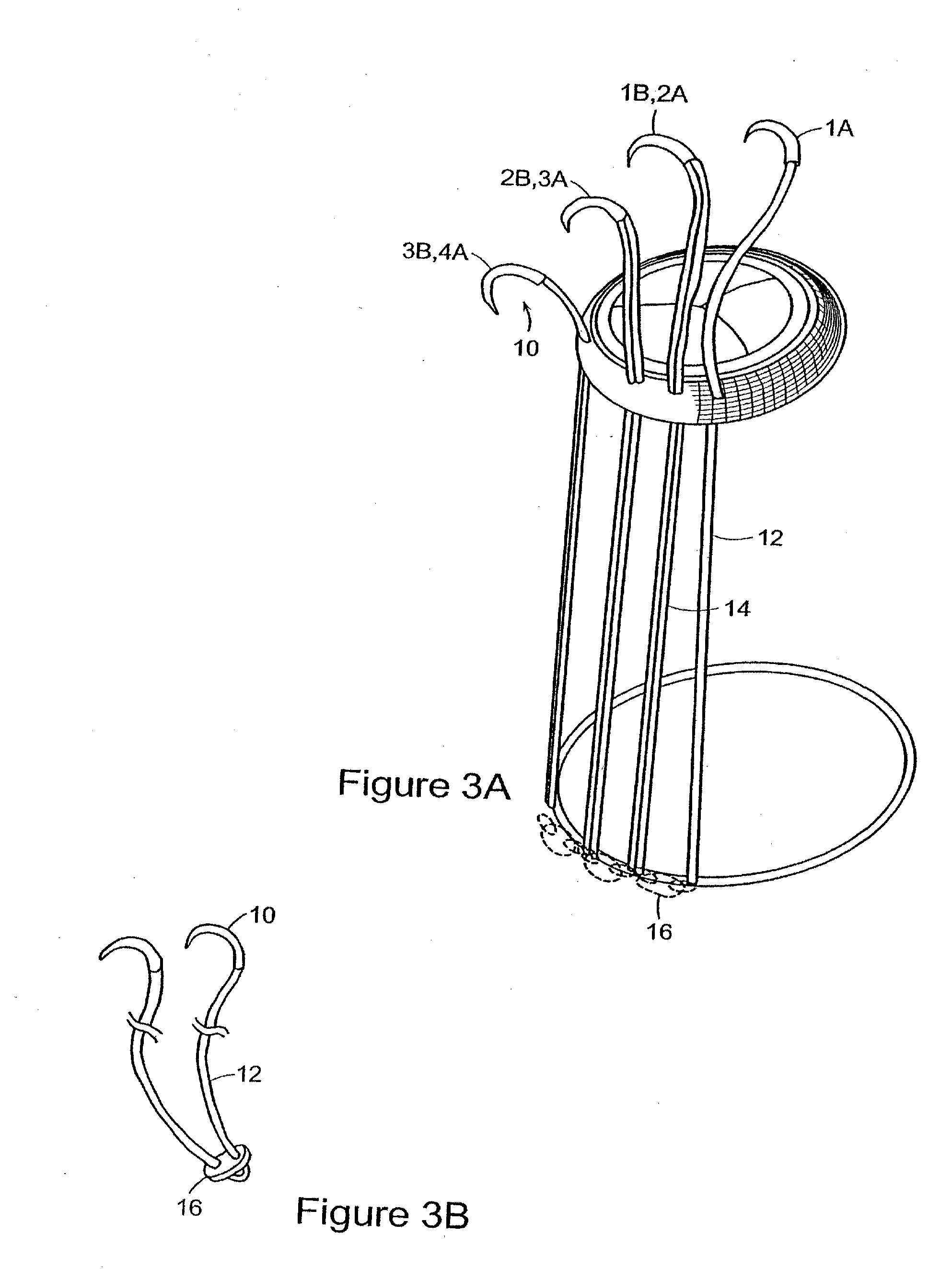

[0027]The present invention relates to a suture system for implanting valved prostheses. Valve implantation, such as cardiac valve implantation, consists of complex suturing process. This includes the placement of multiple mattress sutures in the tissue at the valve site, as well as to the suturing ring or cuff of the valve prostheses. This procedure is complicated by a very small working space inside the arteriotomy or aortotomy in order to excise the diseased native valve, then implant the prosthetic valve. In order to prevent perivalvular leakage and proper seating of the prosthetic valve, the surgeon normally places multiple (i.e., 14 or more) double-ended, pledgeted sutures in mattress or other configuration through both the in-situ annulus of the native, removed valve, and the suturing ring or cuff of the prosthetic valve. The suture strands are made of nonabsorbable polyester and are of a fixed length with a needle attached on both ends. The pledgets are made of PTFE or simil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com