Sewing machine and method of controlling operation of the same

a sewing machine and operation method technology, applied in the direction of sewing machine control devices, sewing apparatus, textiles and paper, etc., can solve the problems of deteriorating affecting and the inability of the conventional sewing machine to process a comparatively large object, so as to enhance the quality of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

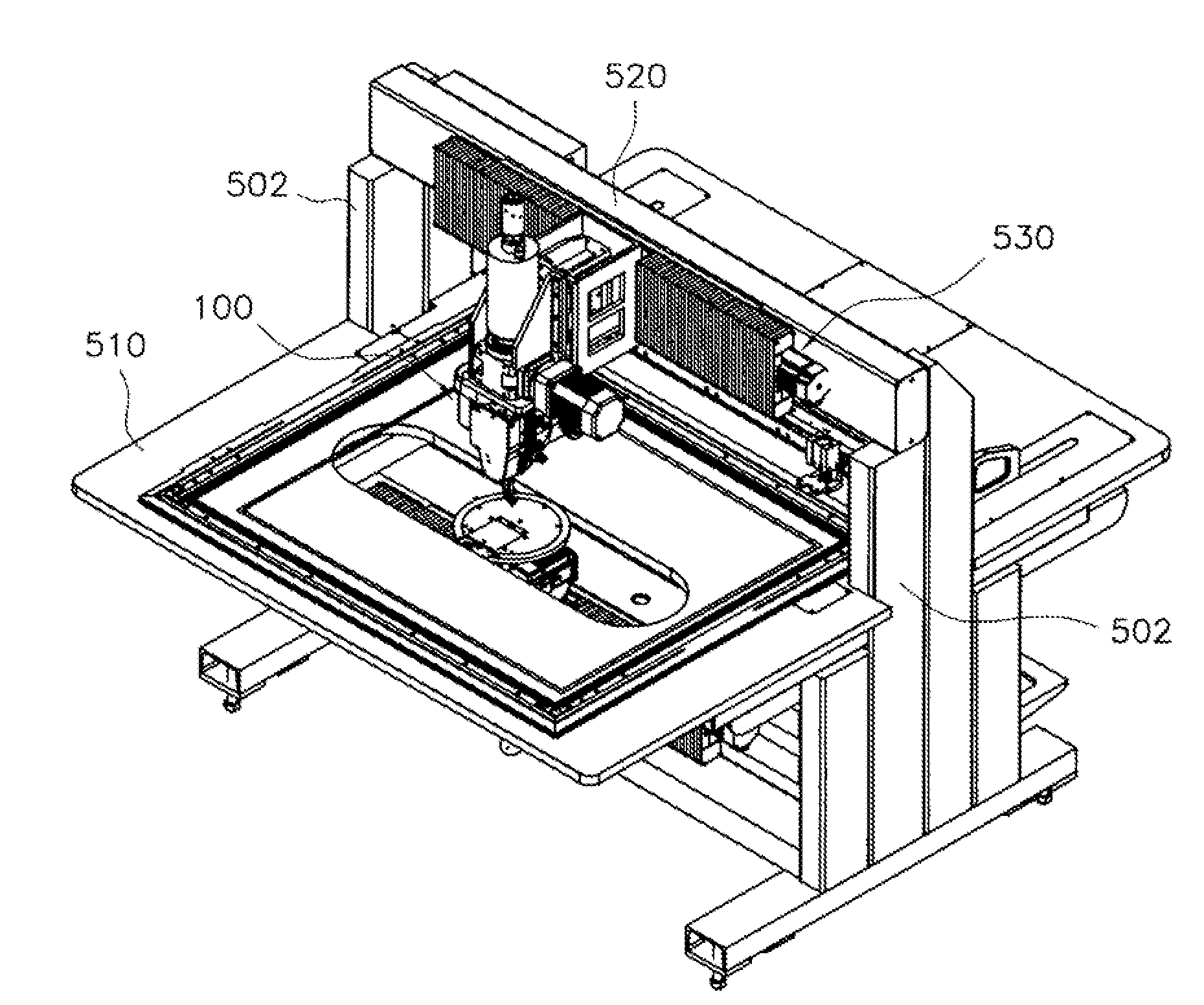

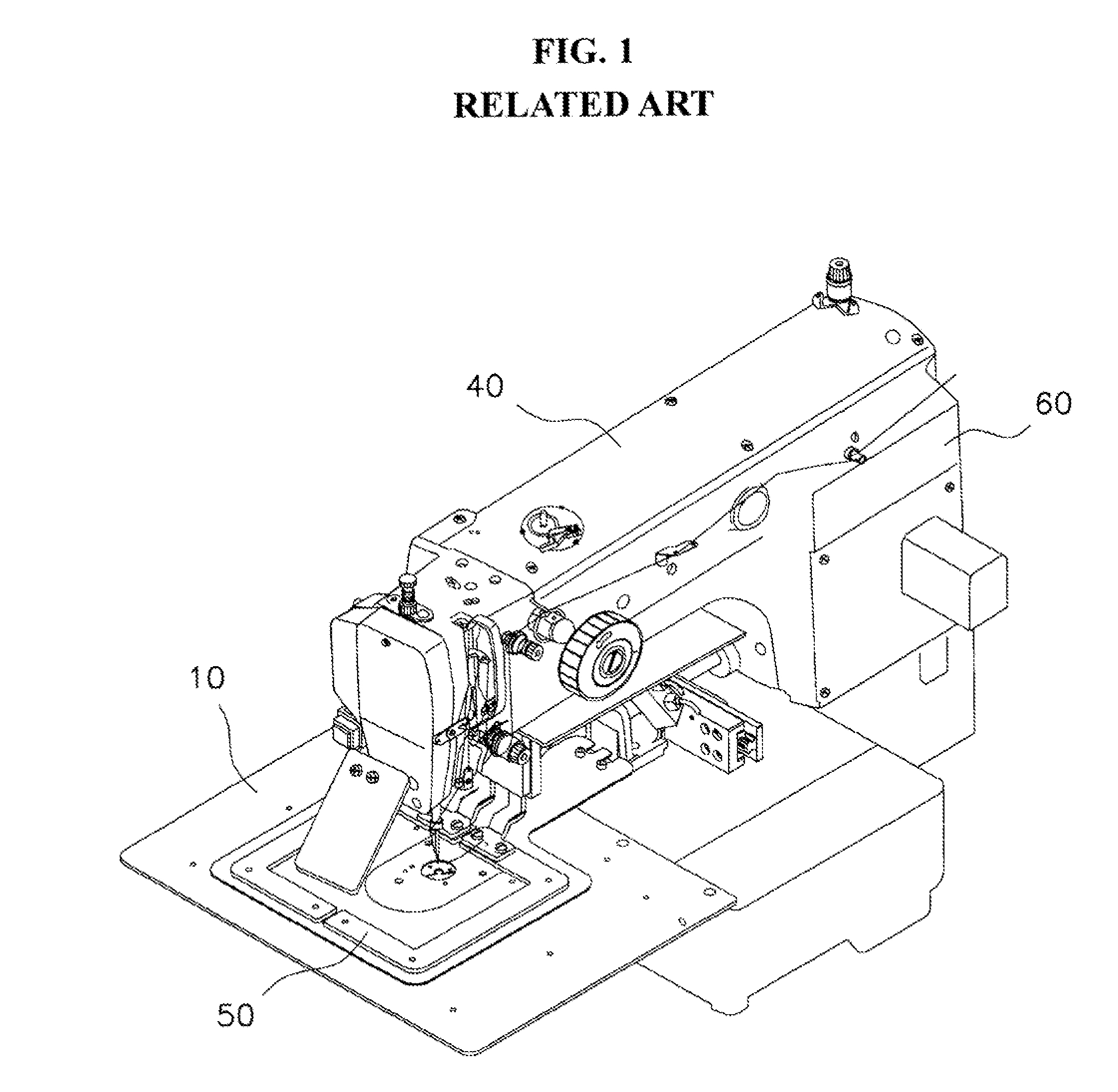

[0072]FIG. 3 is a perspective view illustrating a head-unit-moving-bridge type sewing machine, according to the present invention. FIG. 4A is a front view illustrating the head-unit-moving-bridge type sewing machine according to the present invention. FIG. 4B is a perspective view illustrating a structure for X-axially transporting a head unit and a bed unit of the head-unit-moving-bridge type sewing machine according to the present invention.

[0073]The sewing machine according to the present invention includes a table 510 which receives an object to be sewn, support posts 502 which are provided on opposite sides of the table 510, and an upper frame 520 and a lower frame 521 which connect the support posts 502 to each other and are respectively provided on upper and lower ends of the support posts 502. The head unit 100 and the bed unit 300 are respectively provided on the upper and lower frames 520 and 521 and can be respectively moved along the upper and lower frames 520 and 521 in...

second embodiment

[0112]However, the present invention proposes a structure in which transport screws 534 and 634 of upper and lower shafts are rotated together only by a single motor.

[0113]In detail, the second embodiment of the present invention includes, as the X-axial head-unit-transport means and the X-axial bed-unit-transport means, an integrated X-axial transport motor 550, an upper transport screw 534, a lower transport screw 634, an upper guide rail 538, a lower guide rail 638 and a power transmission means. The integrated X-axial transport motor 550 is provided on one of the support posts 502. The upper transport screw 534 is installed on the upper frame 520. The head unit 100 is connected to the upper transport screw 534. The lower transport screw 634 is installed on the lower frame 521. The bed unit 300 is connected to the lower transport screw 634. The upper guide rail 538 is provided on the upper frame 520 so that the head unit 100 can be transported along the upper frame 520. The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com