Filter Drain Kit and Method

a filter and kit technology, applied in the direction of liquid handling, packaging goods, separation processes, etc., can solve the problems of inconvenient operation in confined spaces, increased oil leakage, and the same attachment of the containment boot, etc., and achieve the effect of small spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

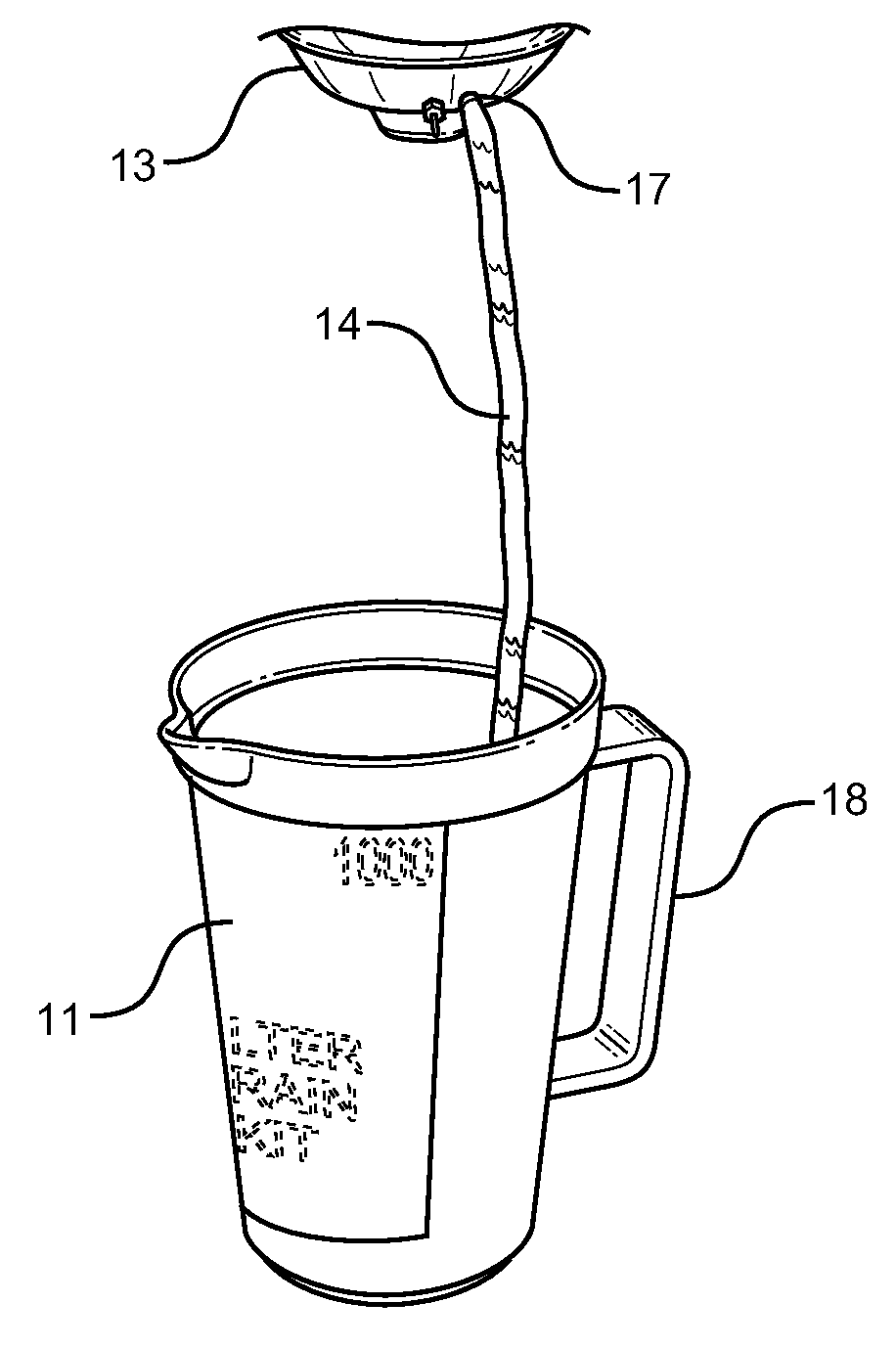

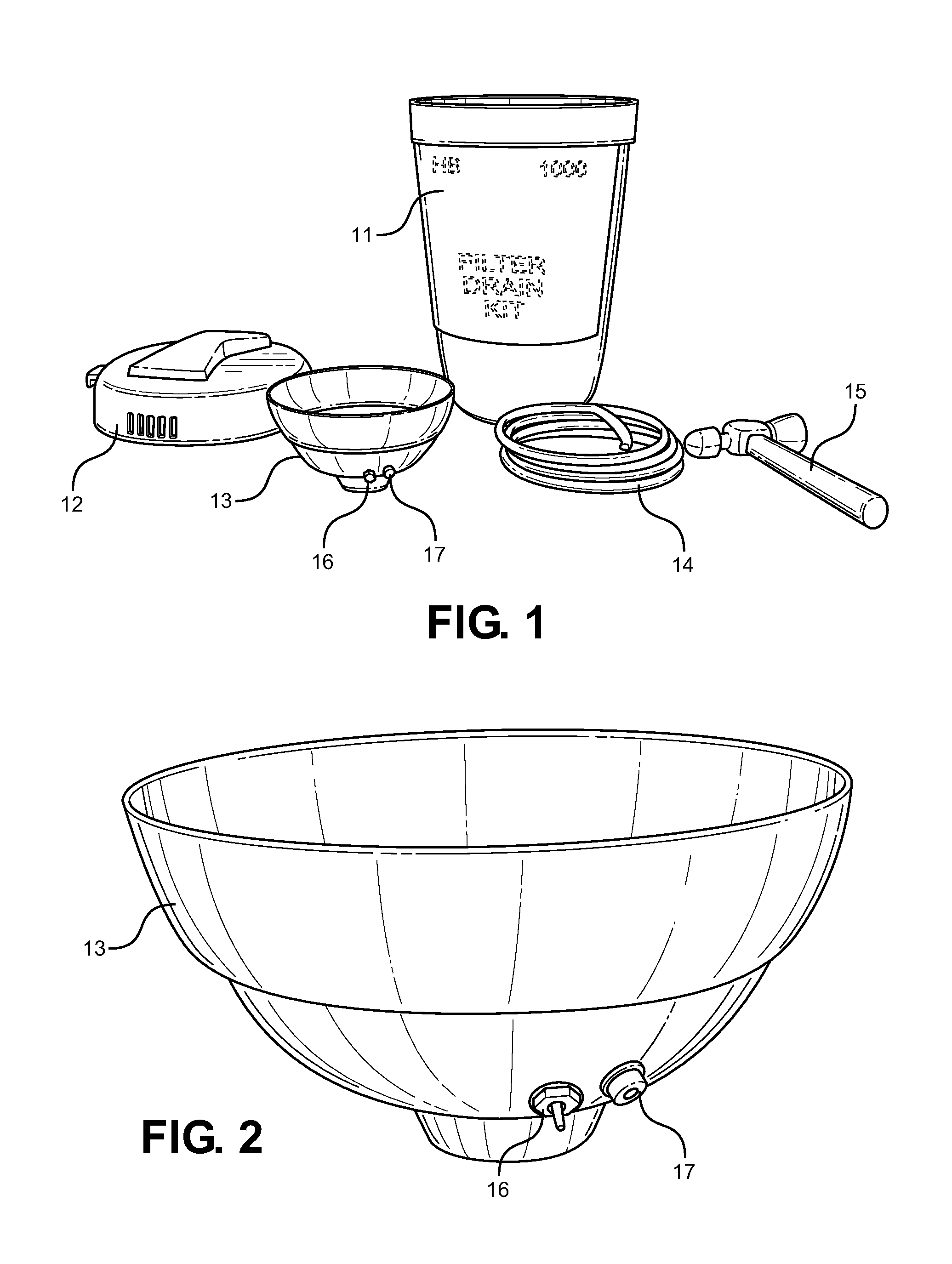

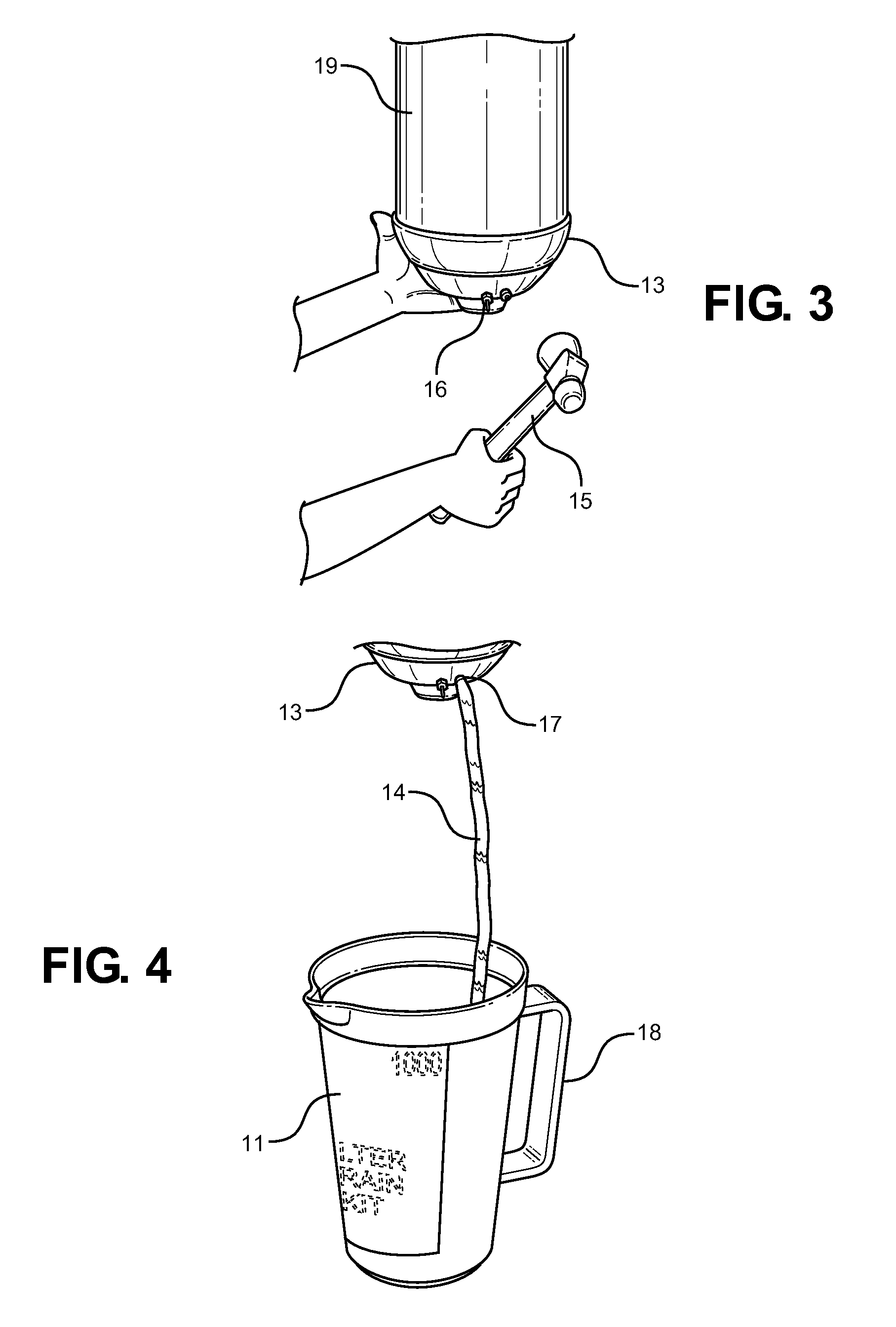

[0030]Referring now to FIG. 1, there is shown the filter drain kit 10 with all the components shown outside of the container 11. Shown is the cylindrical storage container 11, lid 12, flexible drain cup 13, hose 14, and hammer 15 or similar striking device. All items are contained in the storage container 11 when not in use. The flexible drain cup includes a puncture device 16 and drain fitting 17, while the storage container 11 includes a handle 18. The elements of the present invention, as shown in FIG. 1, comprise a kit that provides a user with a means to puncture the end of an oil filter, collect the draining motor oil therefrom without spillage and funnel the oil into a drain hose 14 and into a container 11 that eliminates splash back. The kit is self contained and can be stored together when not in use, and likewise be cleaned and reused for future oil changing operations.

[0031]Referring now to FIG. 2, there is shown a perspective view of the flexible drain cup 13 that is a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Circumference | aaaaa | aaaaa |

| Plasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com