Igniter with a locked consolidated powder charge

a powder charge and ignition charge technology, applied in the direction of electric fuzes, weapons, ammunition fuzes, etc., can solve the problems of sleeve not preventing the rotation of ignition charge, bridge wire failure, cost of additional components,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

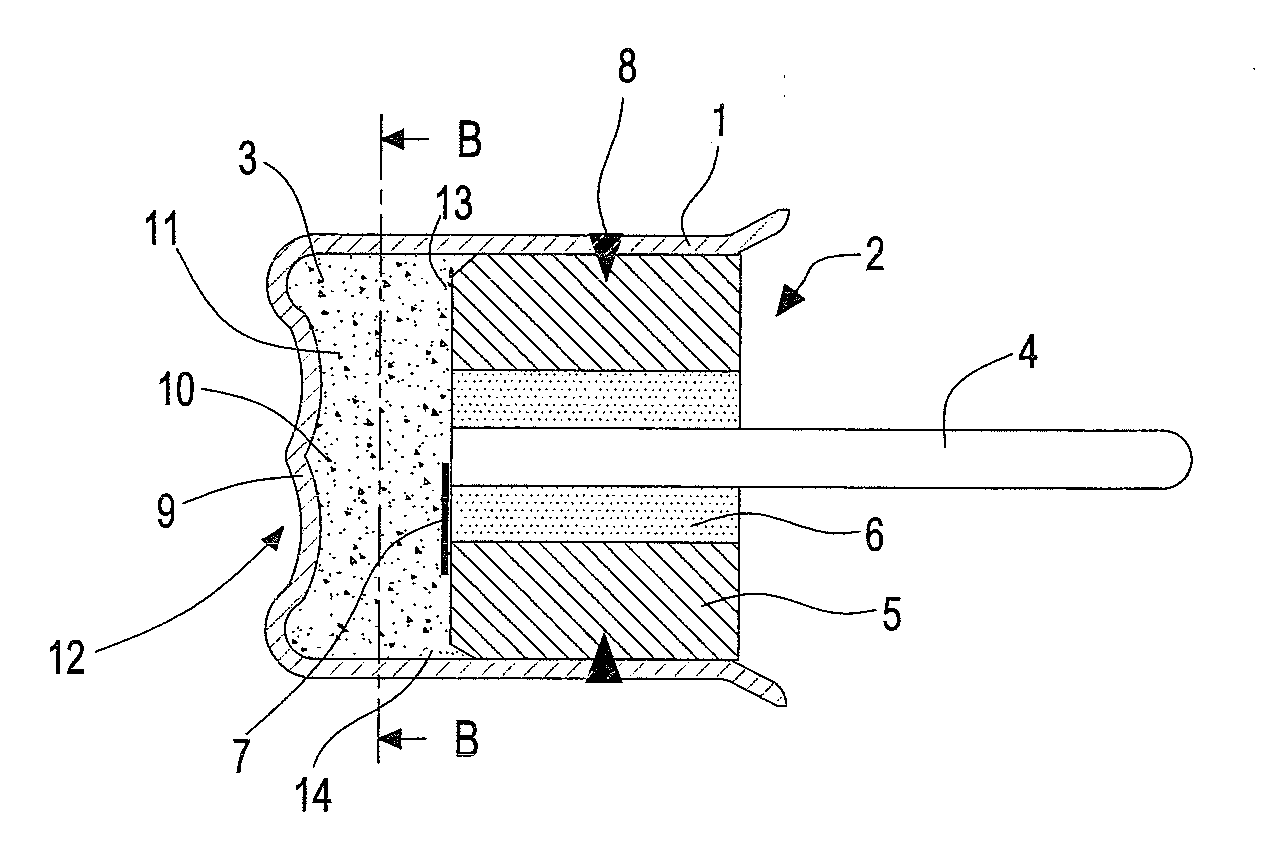

[0032]FIG. 1a shows a sectional view denoted A-A in FIG. 1b of a first embodiment comprising an output can having a consolidated ignition and output powder charge.

[0033]FIG. 1b shows a sectional view denoted B-B in FIG. 1a of the first embodiment shown in FIG. 1a.

second embodiment

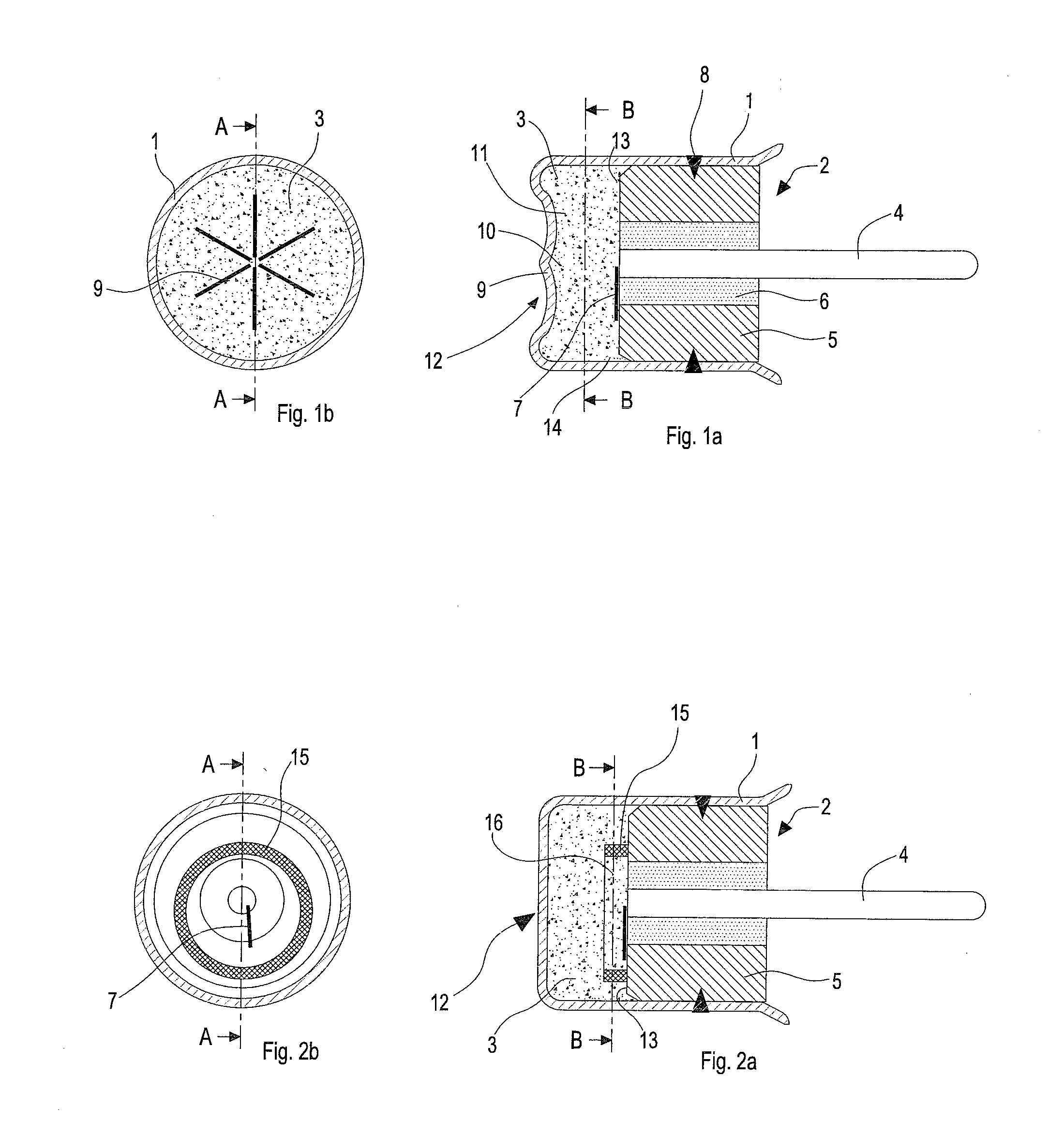

[0034]FIG. 2a shows a sectional view denoted A-A in FIG. 2b of a second embodiment comprising an output can having a consolidated ignition and output powder charge.

[0035]FIG. 2b shows a sectional view denoted B-B in FIG. 2a of the second embodiment shown in FIG. 2a.

third embodiment

[0036]FIG. 3a shows a sectional view denoted A-A in FIG. 3b of a third embodiment comprising an output can having a consolidated ignition and output powder charge.

[0037]FIG. 3b shows a sectional view denoted B-B in FIG. 3a of the third embodiment shown in FIG. 3a.

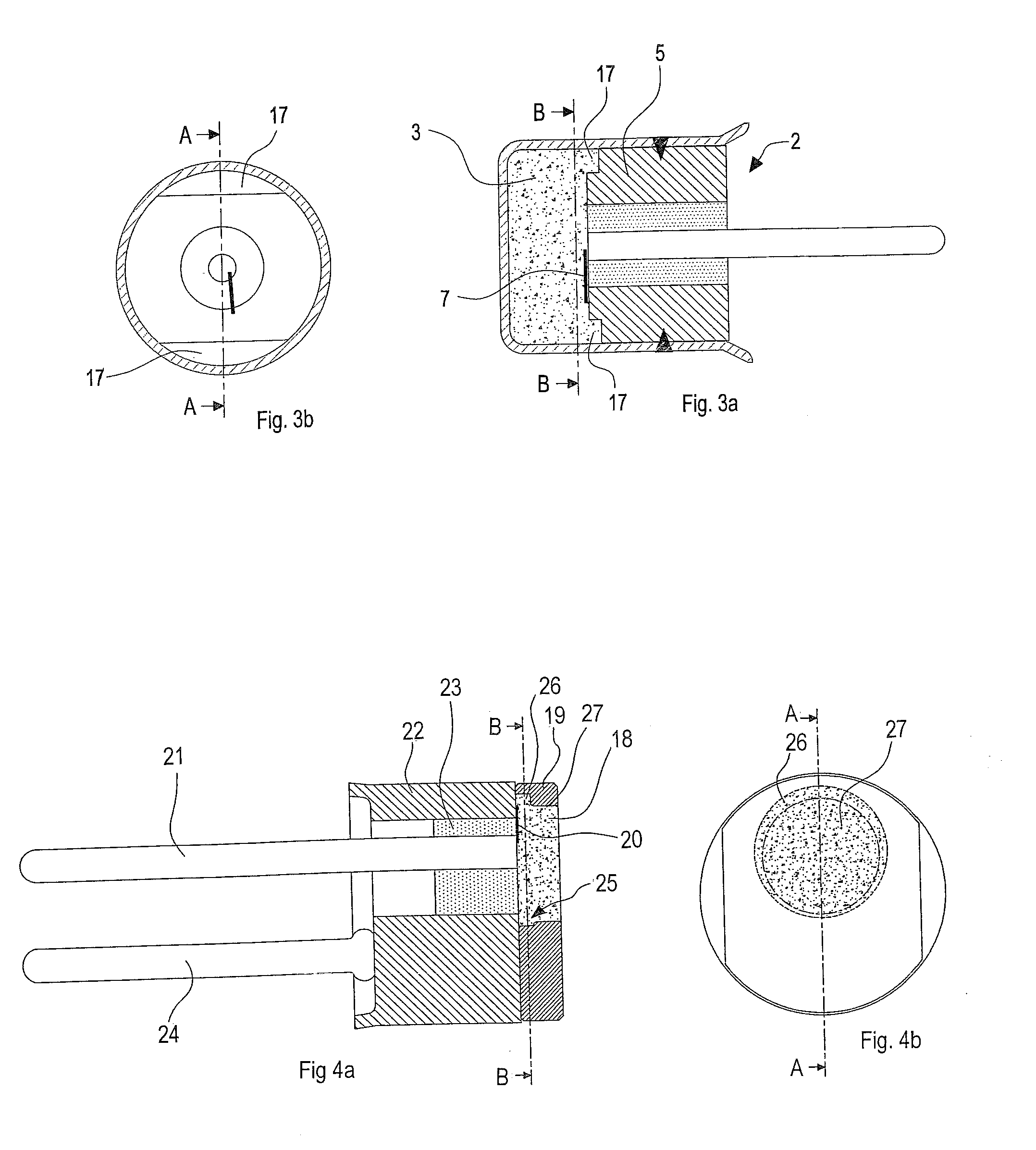

[0038]FIG. 4a shows a sectional view denoted A-A in FIG. 4b of a first embodiment comprising a charge sleeve having a consolidated ignition powder charge.

[0039]FIG. 4b shows a sectional view denoted B-B in FIG. 4a of the first embodiment shown in FIG. 4a.

[0040]FIG. 5a shows a sectional view denoted A-A in FIG. 5b of a second embodiment comprising a charge sleeve having a consolidated ignition powder charge.

[0041]FIG. 5b shows a sectional view denoted B-B in FIG. 5a of the second embodiment shown in FIG. 5a.

[0042]FIG. 6a shows a sectional view denoted A-A in FIG. 6b of a third embodiment comprising a charge sleeve having a consolidated ignition powder charge.

[0043]FIG. 6b shows a sectional view denoted B-B in FIG. 6a of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com