Apparatus for, and method of, forming, filling and closing bags, each with a pouring device

a technology of pouring device and bag, which is applied in the field of apparatus for forming, filling and closing bags, can solve the problems of a relatively long period of time for filling bags, and the potential risk of not tight sealing in the longitudinal seam region, so as to reduce the number of longitudinal seams, fill relatively quickly, and good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Identical parts or elements are designated by the same designations in the figures.

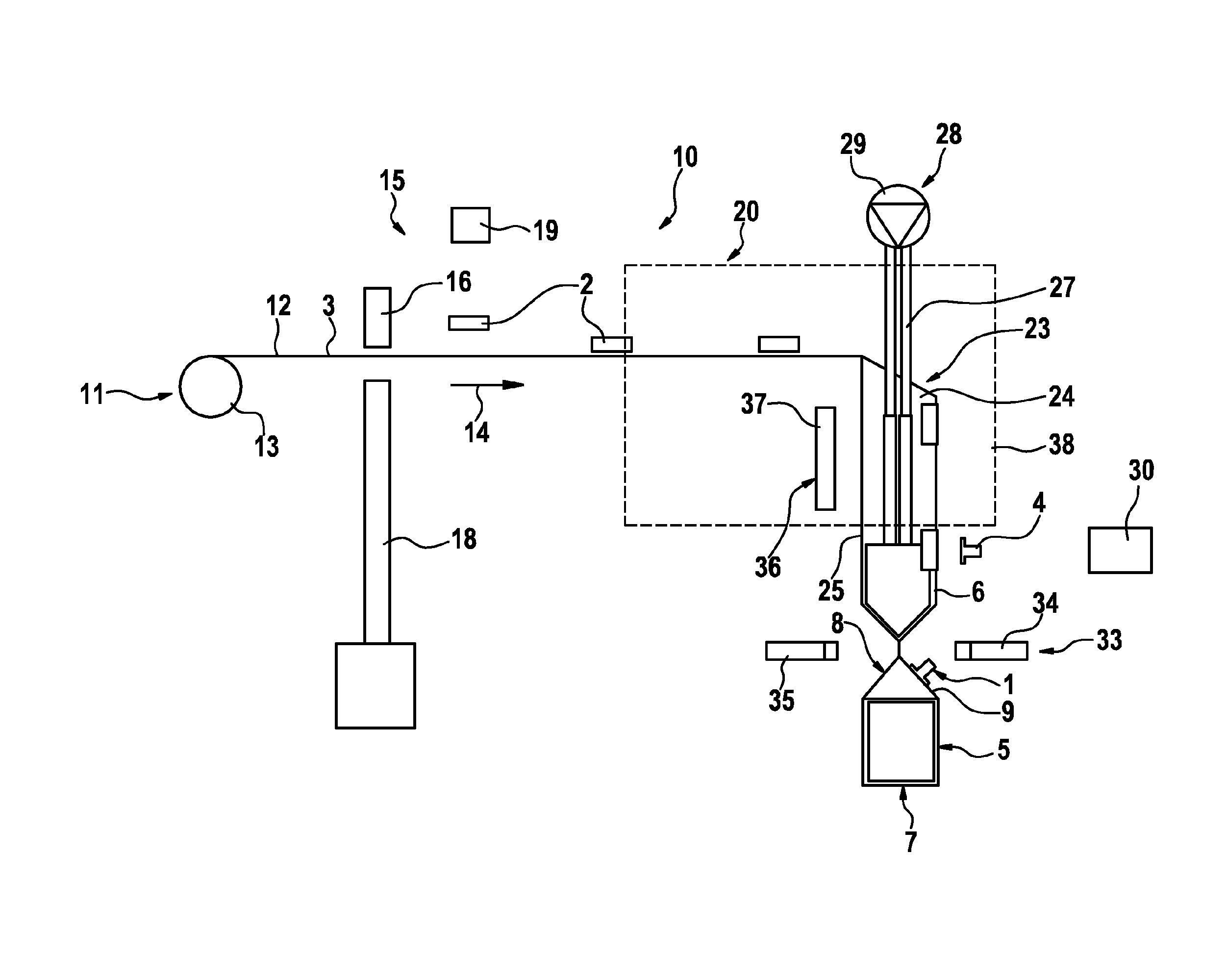

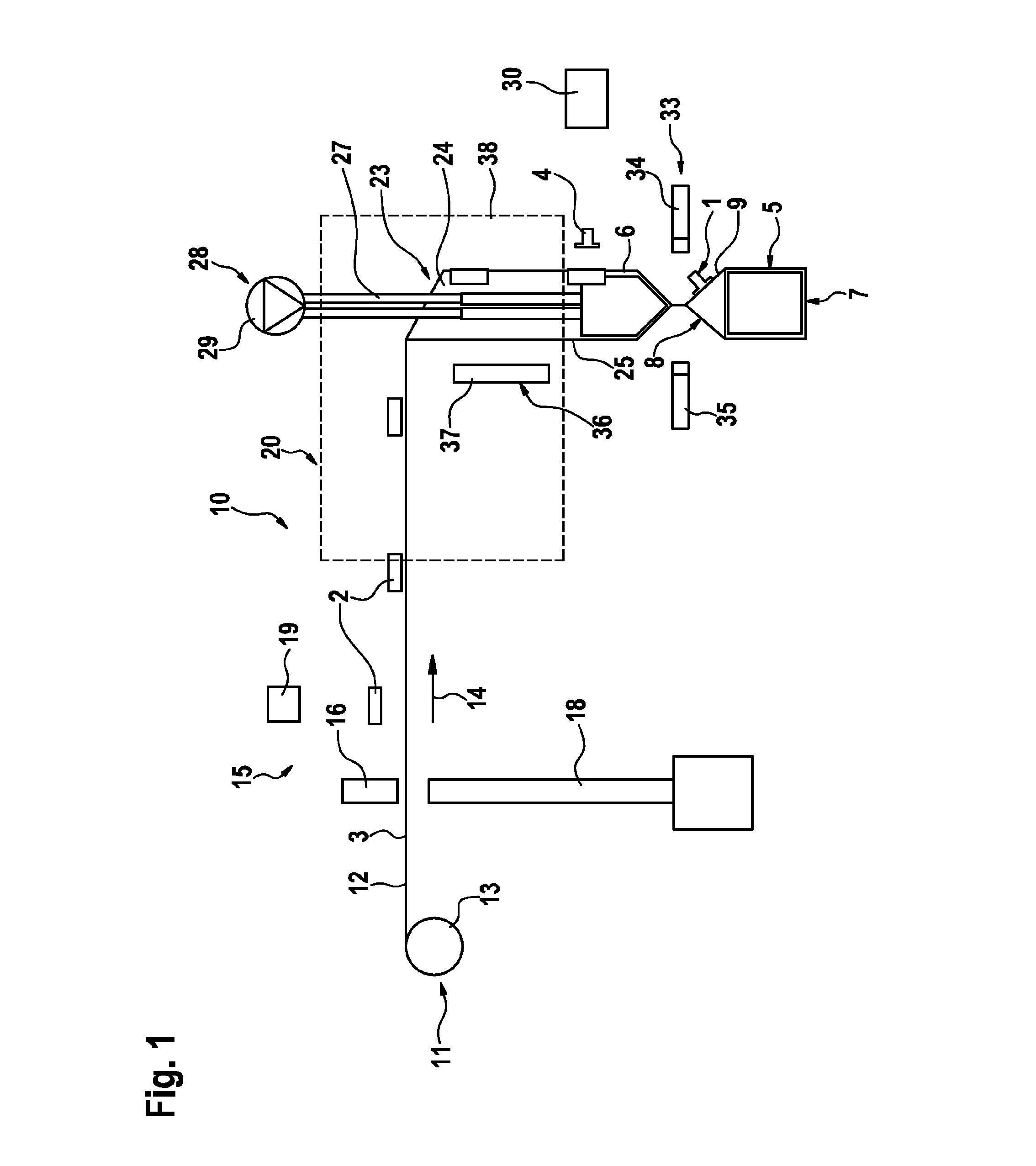

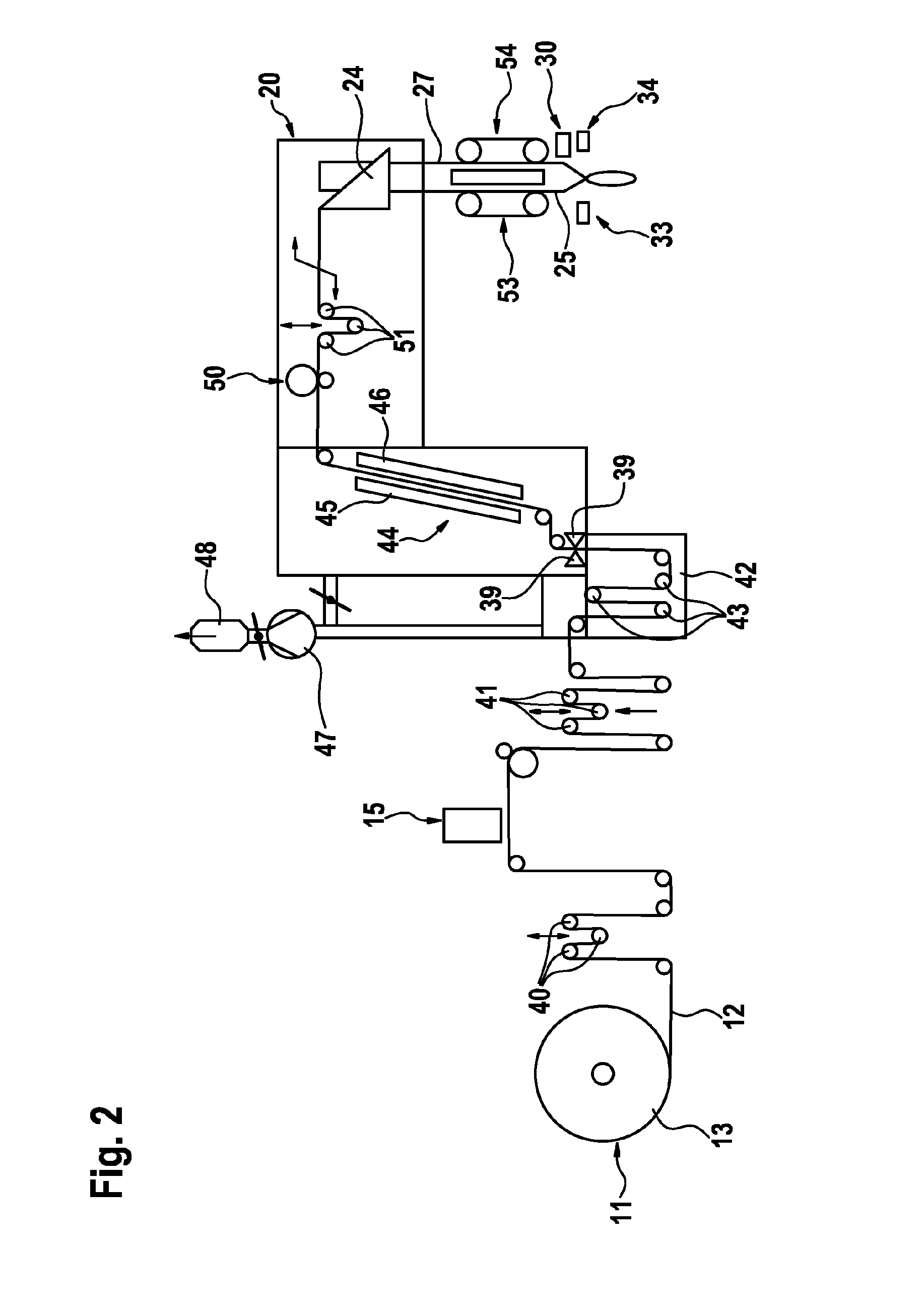

[0024]FIG. 1 illustrates an apparatus 10 for forming, filling and closing bags 5, each with a pouring device 1. The apparatus 10 comprises a storage device 11, in which a flexible material web 12, consisting of heat-sealable plastics material, is stored in the form of a roll 13. Possible materials for the material web here are those which are suitable in the prior art for producing so-called “tubular bags”. As seen in the conveying direction of the material web 12, indicated by the arrow 14, the storage device 11 is followed by a first application device 15 for applying the pouring device 1. The first application device 15 here has, in particular, a punch 16, which punches a hole 131, illustrated in FIG. 6, into the material web 12, wherein the severed, in particular round punching waste is collected by means of a collecting container 18, which is located on that side of the material web 12 whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com