Marangoni stress-driven droplet manipulation on smart polymers for ultra-low voltage digital microfluidics

a smart polymer and stress-driven technology, applied in the field of digital microfluidic systems for the manipulation of liquid droplets, can solve the problems of oxidizing smart polymers, surface hydrophilicity, and loss of positive charges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

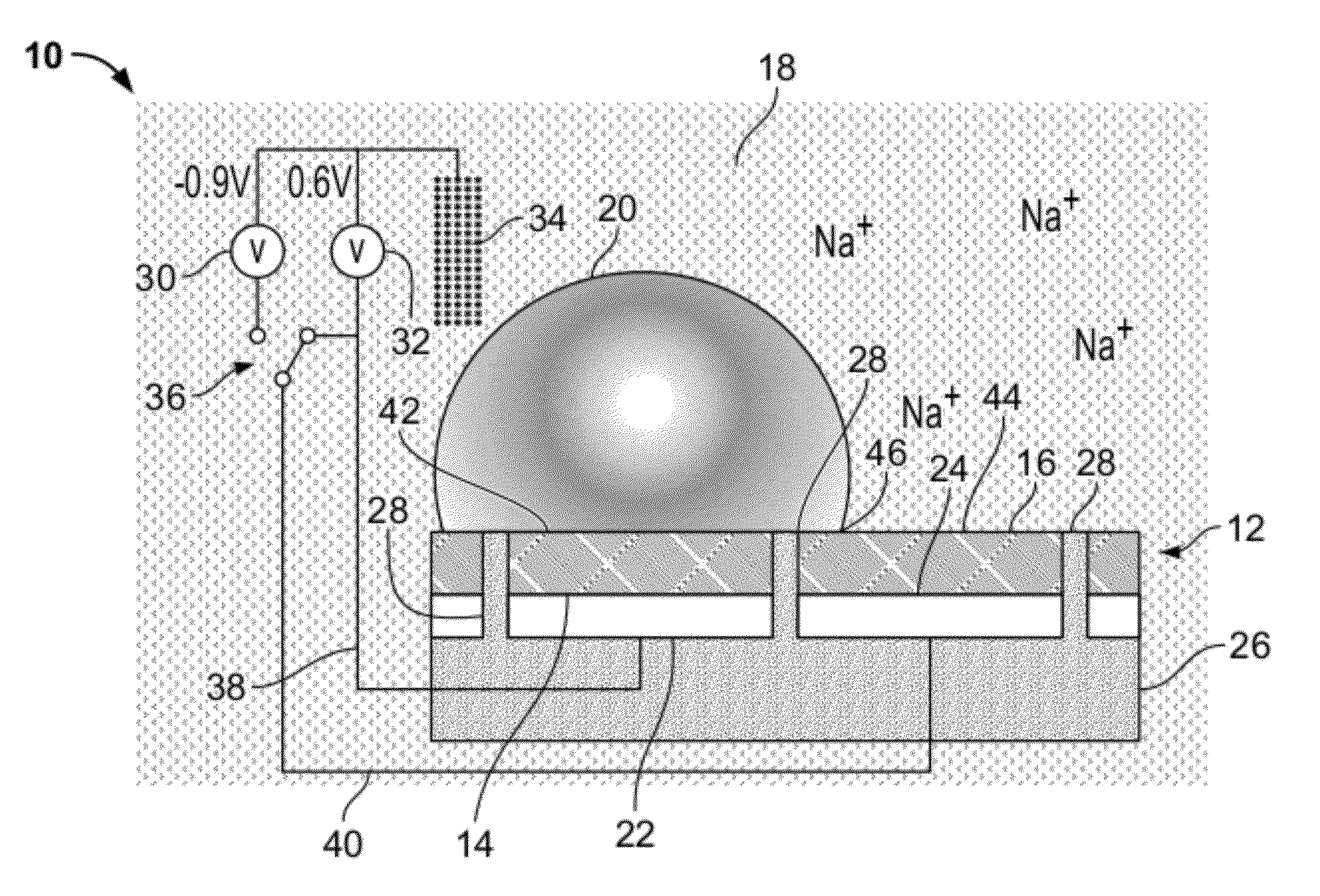

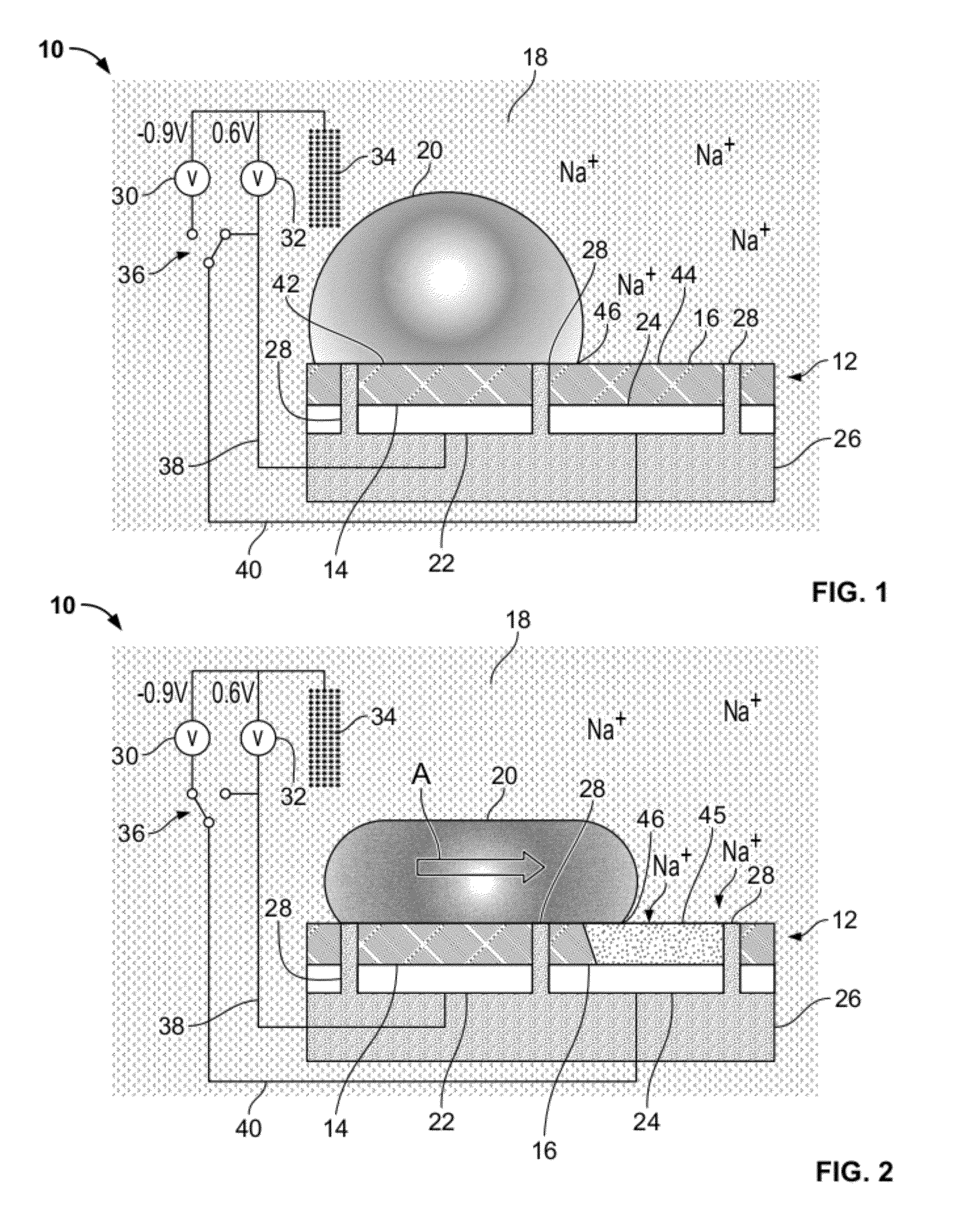

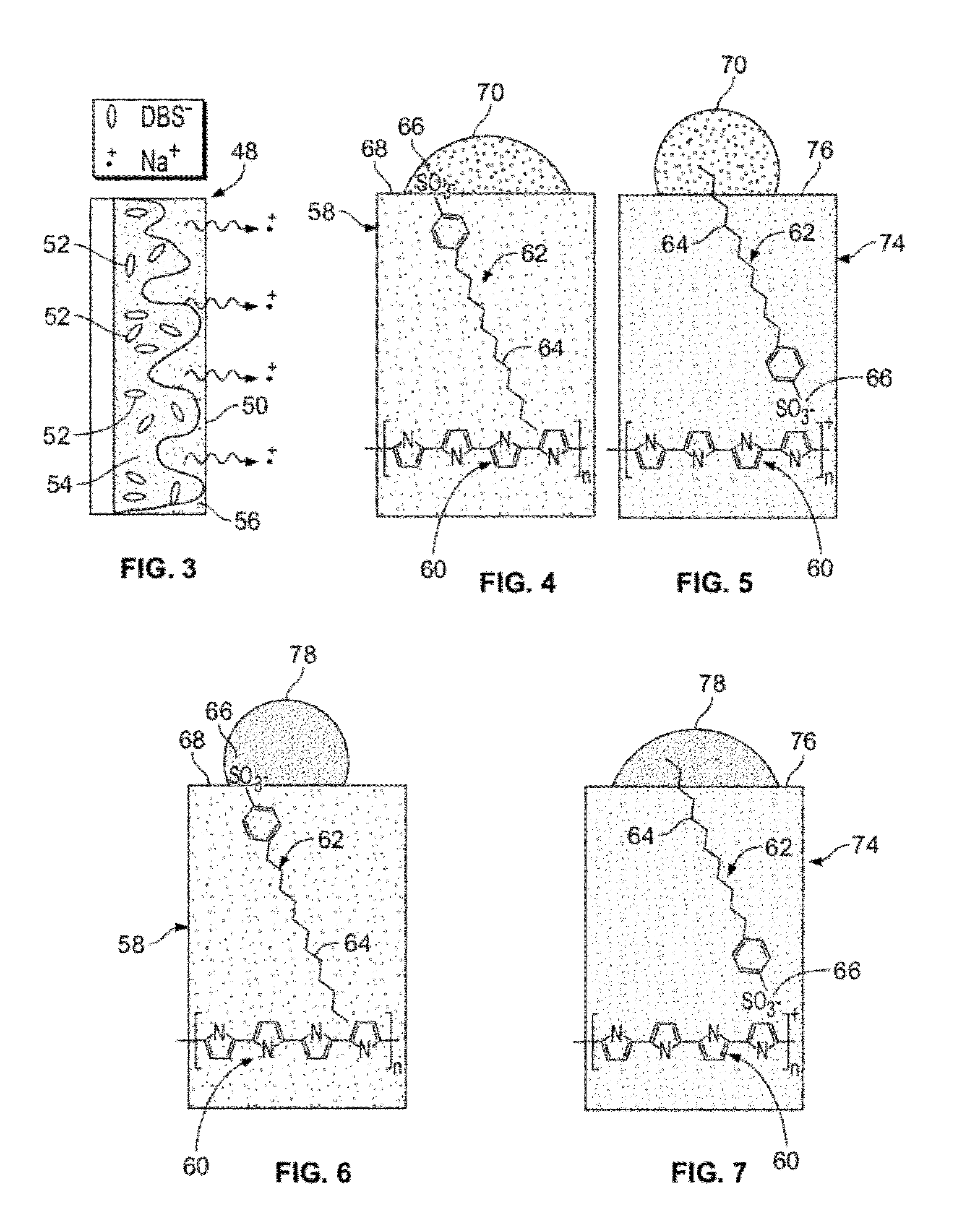

[0023]The Marangoni effect is the mass transfer along an interface between two fluids (e.g., an electrolytic bath and a droplet of immiscible liquid within the bath) due to a surface tension gradient. Since a liquid with high surface tension pulls more strongly on the surrounding liquid than one with a low surface tension, the presence of a gradient in surface tension causes the liquid to move away from a region of low surface tension to a region of high surface tension. The induced force at the liquid-liquid interface is the so-called Marangoni stress.

[0024]The present invention provides a microfluidic system that enables the operation of microfluidic devices at low voltages, such as those which can be provided by commercial-standard 1.5 V batteries, using the Marangoni effect to induce Marangoni stress between adjacent electrodes comprising a smart polymer. Certain embodiments of the present invention can be substituted for those employing the existing electrowetting-on-dielectric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com