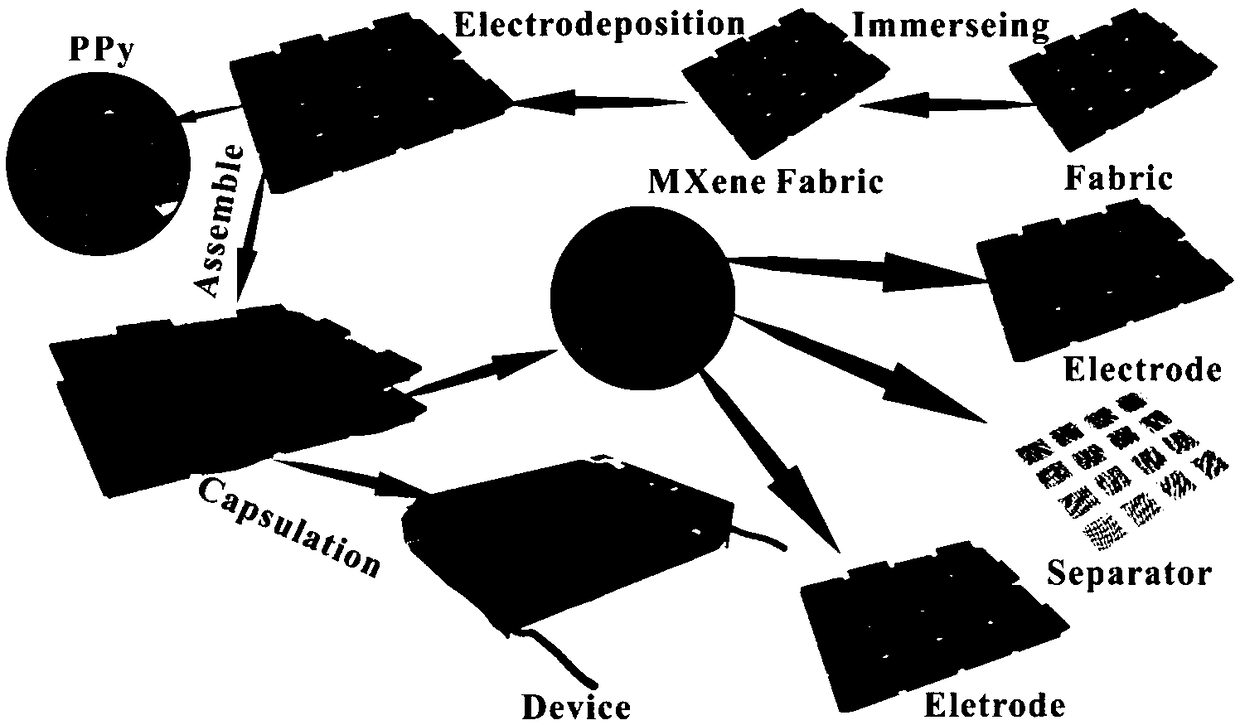

A method for preparing an MXene-based flexible fabric electrode and application thereof to a supercapacitor

A technology of supercapacitors and flexible fabrics, which is applied in the field of nanomaterials and functional devices, can solve the problems of high cost of flexible electrodes and complicated manufacturing processes, and achieve the effects of low cost, simple preparation process, and increased capacitance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

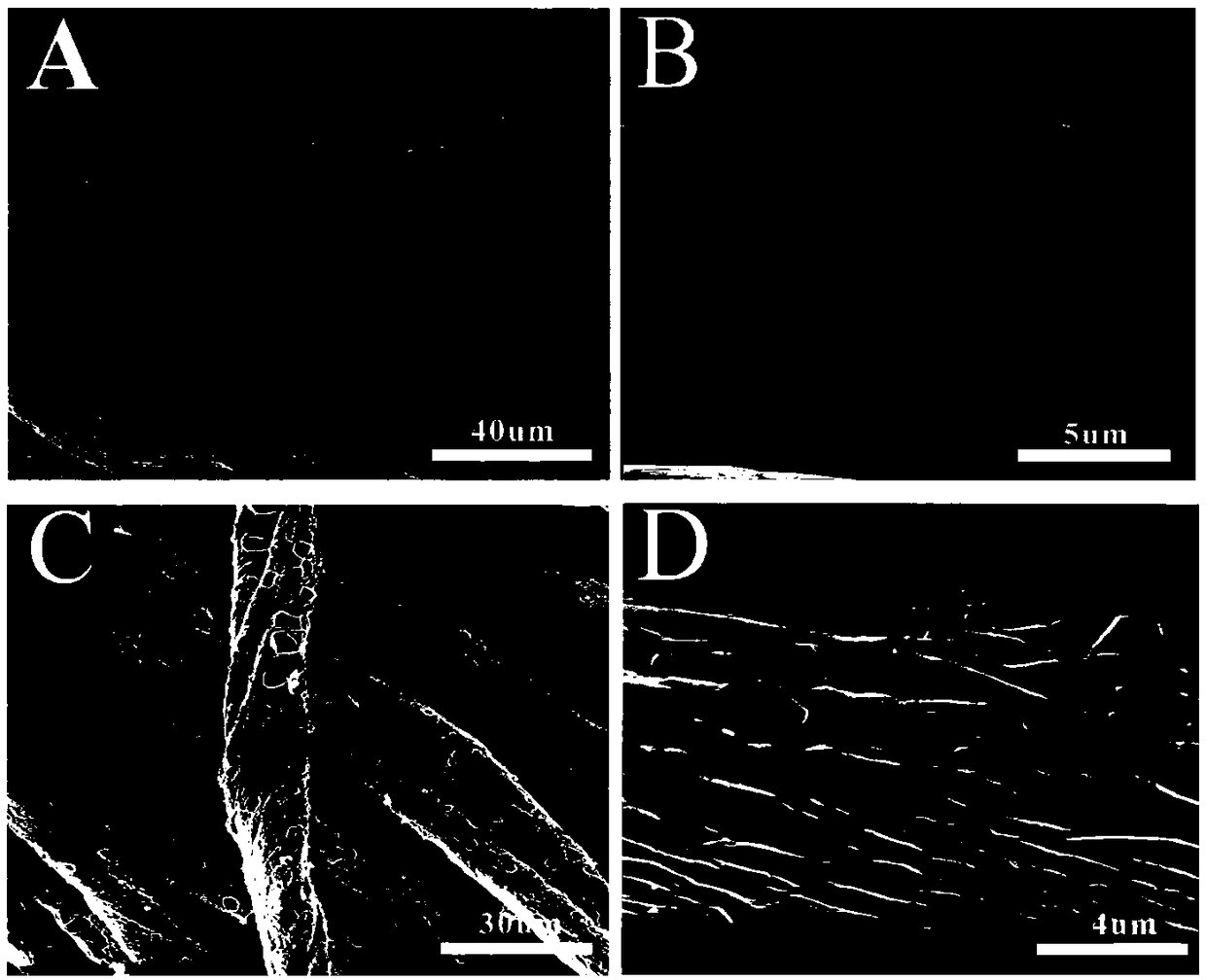

[0053] In a preferred embodiment of the present invention, a kind of preparation method based on MXene flexible fabric electrode, this method comprises the steps:

[0054] (1) Preparation of precursor Ti 3 AlC 2 MAX phase powder.

[0055] Weigh TiH 2 , Al and C powder, mixed in a ratio of 3:1.1:2 and placed in a ball mill, ball milled for 18 hours, and then the powder after ball milling was placed in a corundum crucible and sintered in a vacuum tube furnace under the protection of an argon atmosphere. The sintering conditions The temperature was raised to 1400°C at 10°C / min and kept for 2h. After natural cooling, the obtained Ti 3 AlC 2 After grinding, pass through a 400-mesh sieve to obtain the MAX phase powder.

[0056] (2) Etching the MAX phase, centrifugal cleaning, and low-temperature ultrasonication to prepare MXene.

[0057] A mixed solution of LiF and HCl was used to etch the MAX phase powder in (1) for 24 hours, and the etchant was subjected to repeated centrif...

Embodiment 2

[0074] In a preferred embodiment of the present invention, a kind of preparation method based on MXene flexible fabric electrode, this method comprises the steps:

[0075] (1) Preparation of precursor Ti 3 AlC 2 MAX phase powder.

[0076] Weigh TiH 2 , Al and C powder, mixed in a ratio of 3:1.1:2 and placed in a ball mill, ball milled for 18 hours, and then the powder after ball milling was placed in a corundum crucible and sintered in a vacuum tube furnace under the protection of an argon atmosphere. The sintering conditions The temperature was raised to 1400°C at 10°C / min and kept for 2h. After natural cooling, the obtained Ti 3 AlC 2 After grinding, pass through a 400-mesh sieve to obtain the MAX phase powder.

[0077] (2) Etching the MAX phase, centrifugal cleaning, and low-temperature ultrasonication to prepare MXene.

[0078] A mixed solution of LiF and HCl was used to etch the MAX phase powder in (1) for 24 hours, and the etching solution was subjected to repeate...

Embodiment 3

[0097] In a preferred embodiment of the present invention, a kind of preparation method based on MXene flexible fabric electrode, this method comprises the steps:

[0098] (1) Preparation of precursor Ti 3 AlC 2 MAX phase powder.

[0099] Weigh TiH 2 , Al and C powders, mixed in a ratio of 3:1.1:2 and placed in a ball mill, ball milled for 24 hours, and then the ball milled powder was placed in a corundum crucible and sintered in a vacuum tube furnace under the protection of an argon atmosphere. The sintering conditions The temperature was raised to 1400°C at 10°C / min and kept for 2h. After natural cooling, the obtained Ti 3 AlC 2 After grinding, pass through a 400-mesh sieve to obtain the MAX phase powder.

[0100] (2) Etching the MAX phase, centrifugal cleaning, and low-temperature ultrasonication to prepare MXene.

[0101] The mixed solution of LiF and HCl was used to etch the MAX phase powder in (1) for 18 hours, and the etchant was subjected to repeated centrifugal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com