Meat processing assembly

a technology for processing assembly and meat, which is applied in the direction of machines/engines, liquid fuel engines, applications, etc., can solve the problems of affecting the service life of meat pumps, so as to reduce heat, facilitate the installation and removal of gears, and reduce the effect of hea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

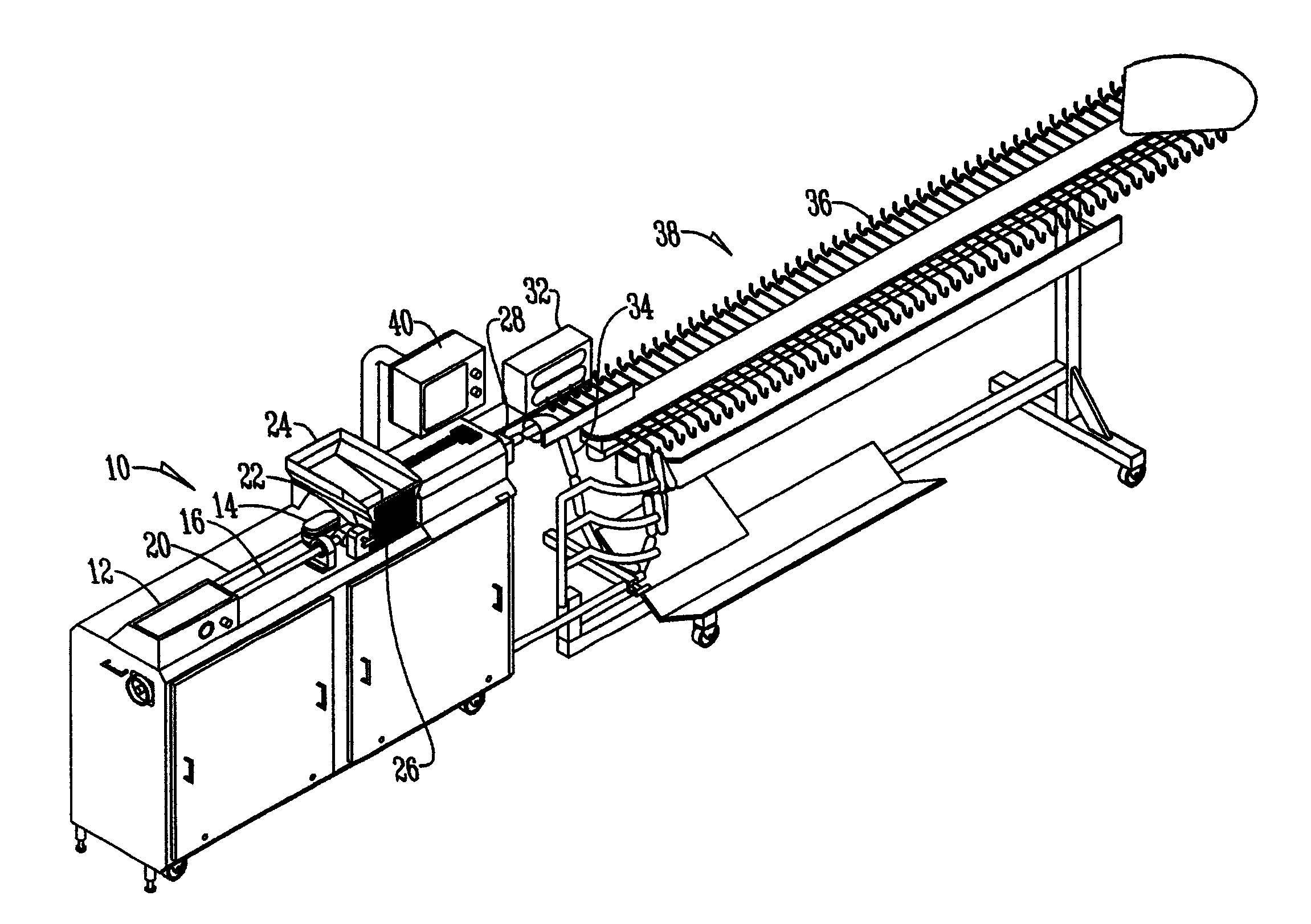

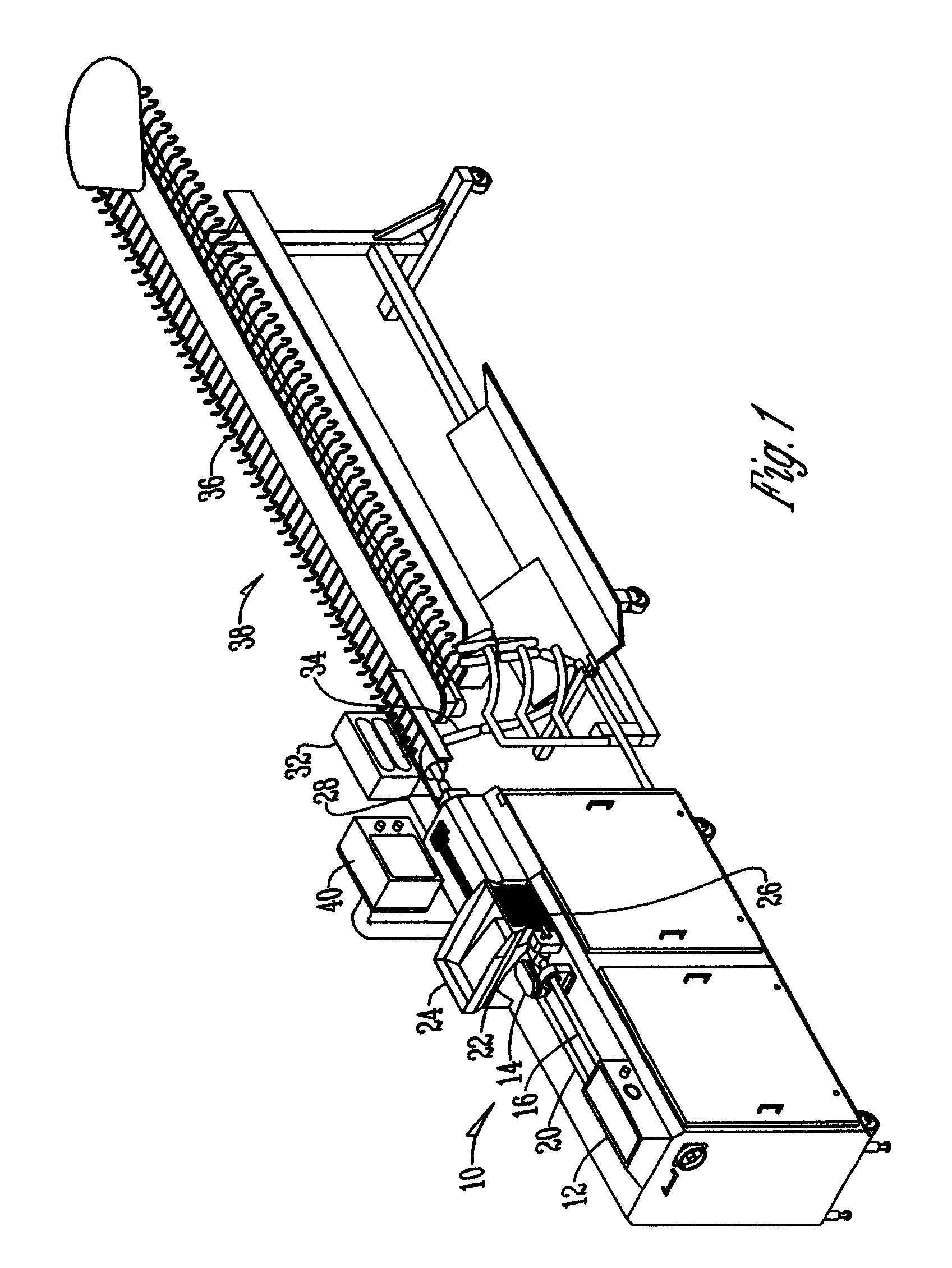

[0030]Referring to the Figures, the meat processing assembly 10 has a frame 12 with a meat emulsion pump 14 connected to a source of meat emulsion (not shown). A stuffing horn 16 is slidably and operably connected to the pump 14 and is longitudinally moveable by a horn adjustment assembly 18 that is slidably mounted to guide shaft or cylinder carriage 20. An elongated shirred casing 22 is mounted on horn 16 from casing hopper 24 where the forward end of the horn 16 terminates at casing filling station 26 adjacent twister housing 28. The twister 28 has a hollow rotatable chuck 30 which receives filled casing 22 and rotates the casing 22 before the filled casing moves into linker 32. The completed strands of sausage 34 exit the linker 32 and are deposited on hooks 36 of conveyor 38. The foregoing components are connected to and controlled by computer control 40.

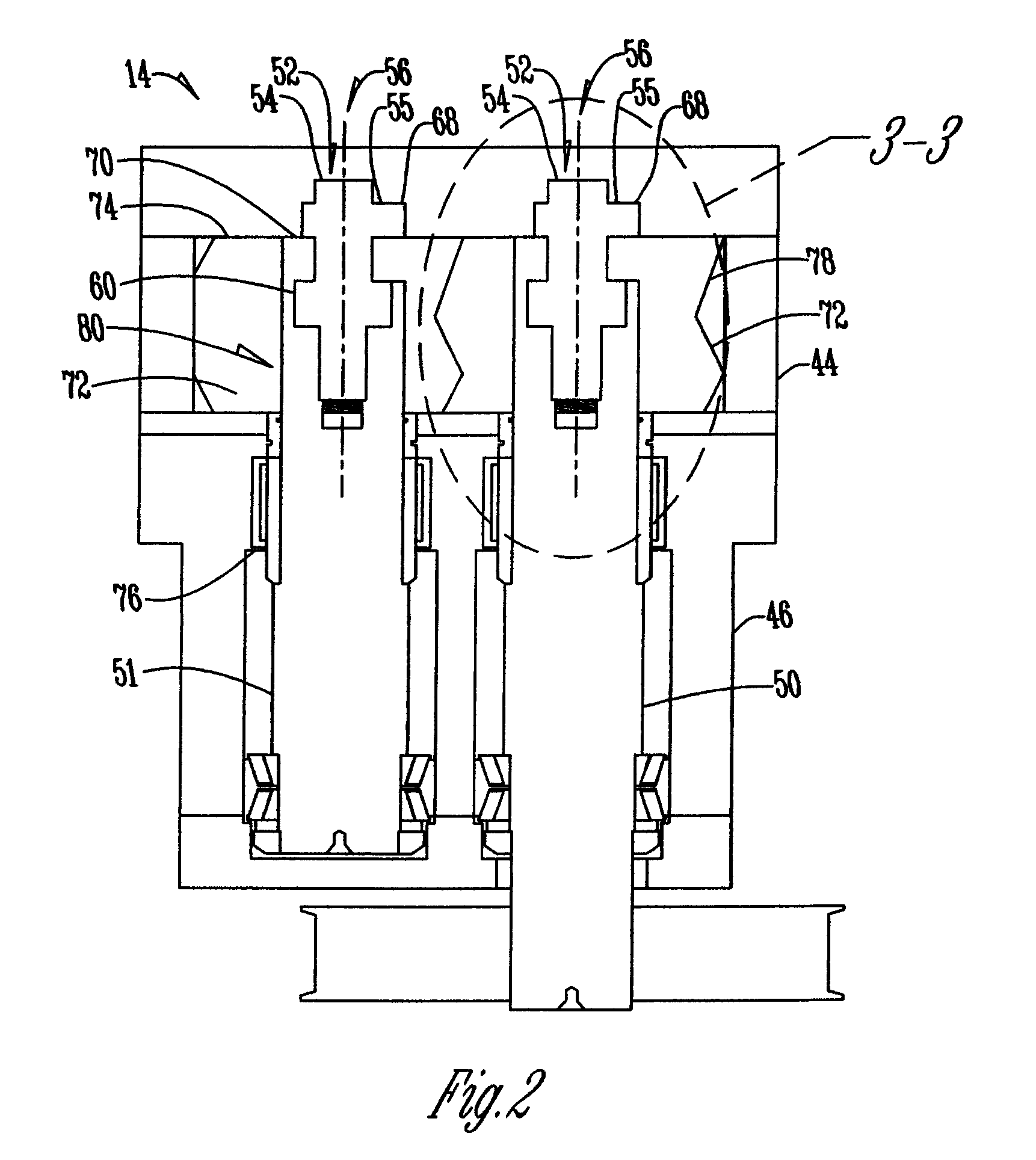

[0031]Pump 14 has a gear housing 44, a pump housing weldment 46, and a pulley driven drive shaft 50 that extends through a bo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap