Quick-installation structure of a toilet seat cover assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Embodiments of the present invention will now be described, by way of example only, with reference to the accompanying drawings.

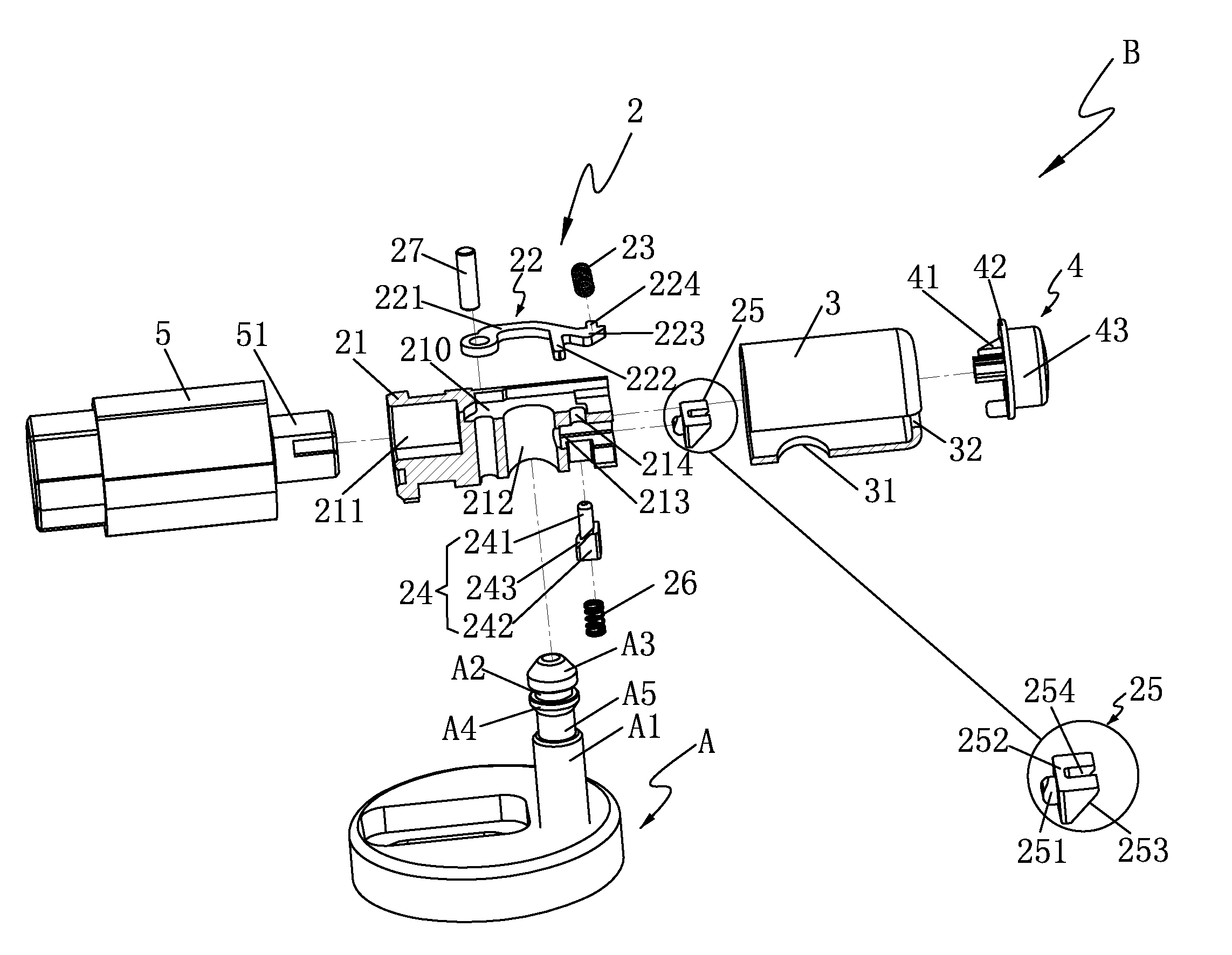

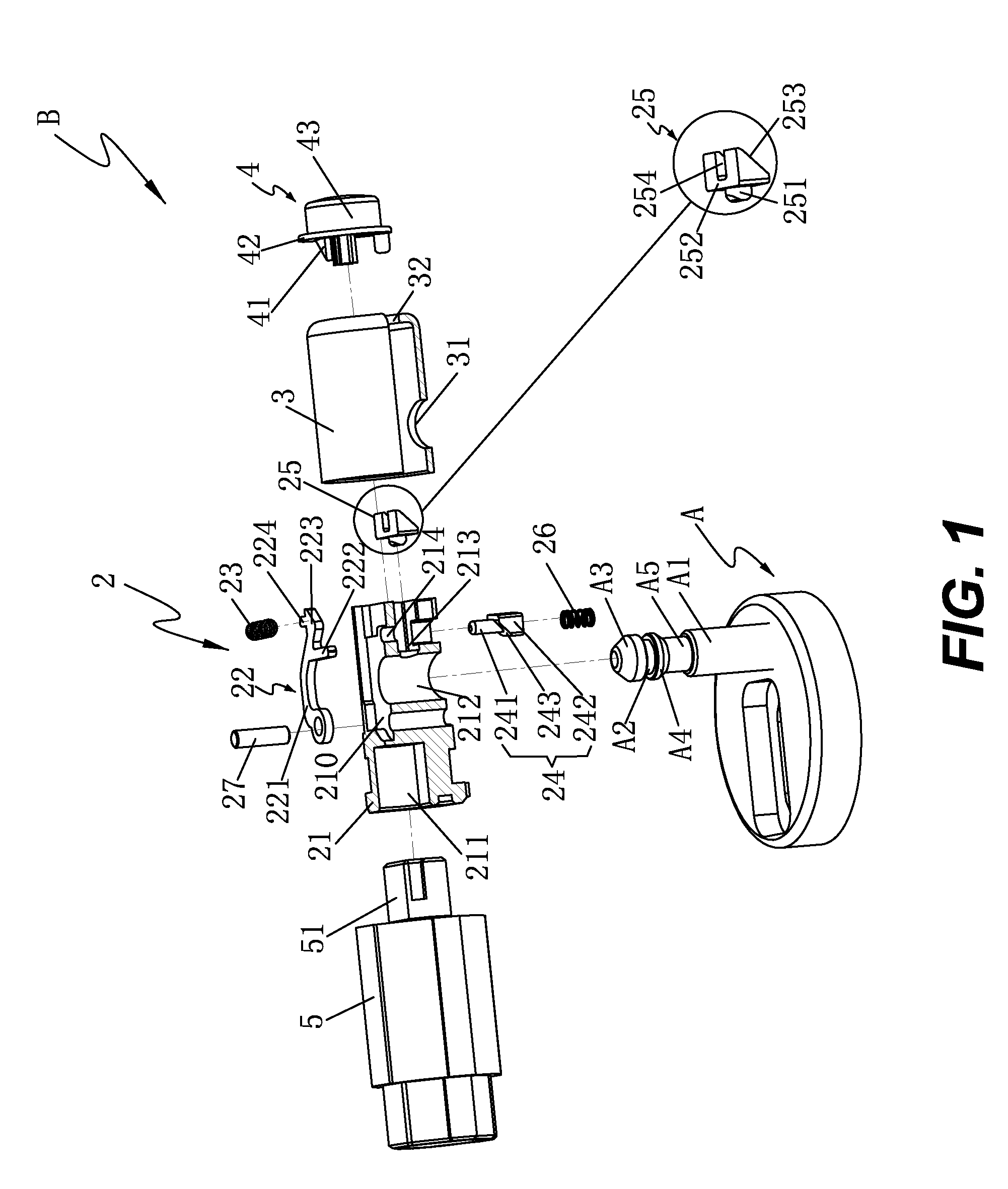

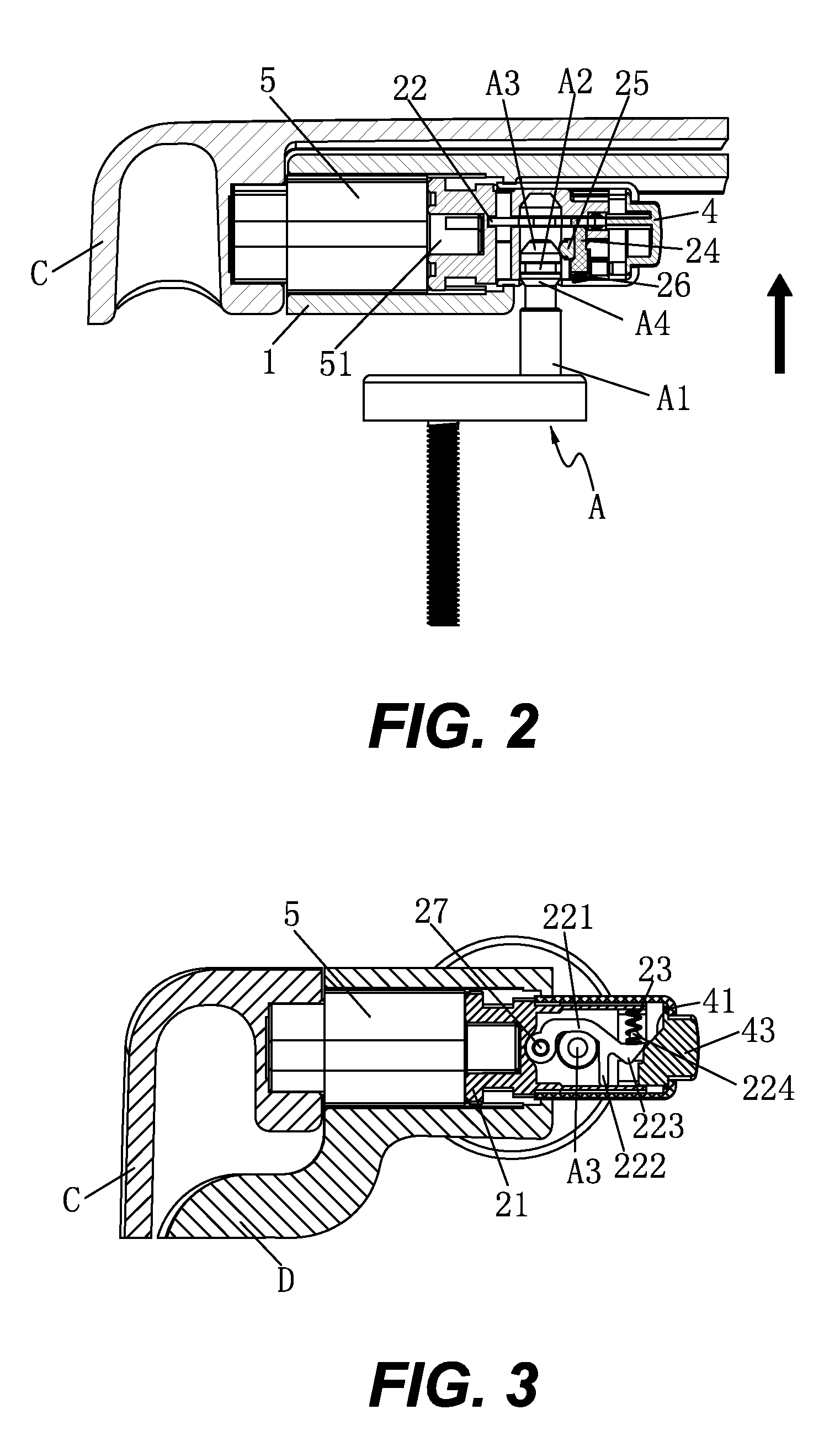

[0030]As shown in FIGS. 1 to 9, a quick-installation structure of a toilet seat cover assembly according to a preferred embodiment of the present invention comprises two bases A which are fixed on a toilet and two connection devices B which are disposed on the toilet seat cover assembly and correspond to the two bases A, respectively. The toilet seat cover assembly includes a cover C and a toilet seat D.

[0031]Each base A has a positioning rod Al thereon. The positioning rod A1 has an annular groove A2 at an upper portion thereof, a cone A3 which has an inclined surface and is located on top of the annular groove A2, a reverse conical surface A4 below the annular groove A2, and a reduced neck A5 below the reverse conical surface A4.

[0032]Each connecting device B includes a sleeve 1 formed on the toilet seat D, a rotating axle 5 fixed to the cover C, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com