Fluid Transfer Device having Modular Connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

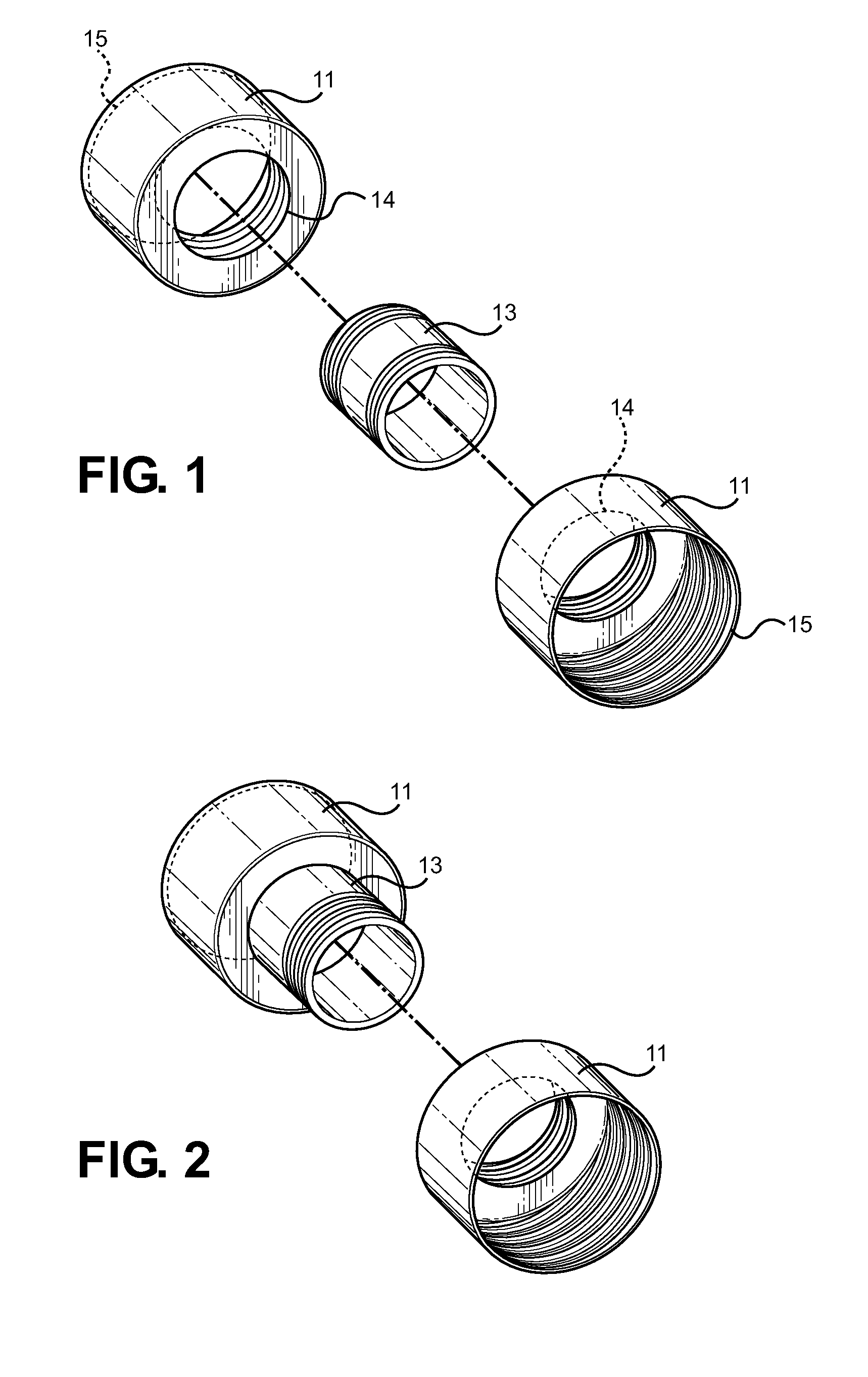

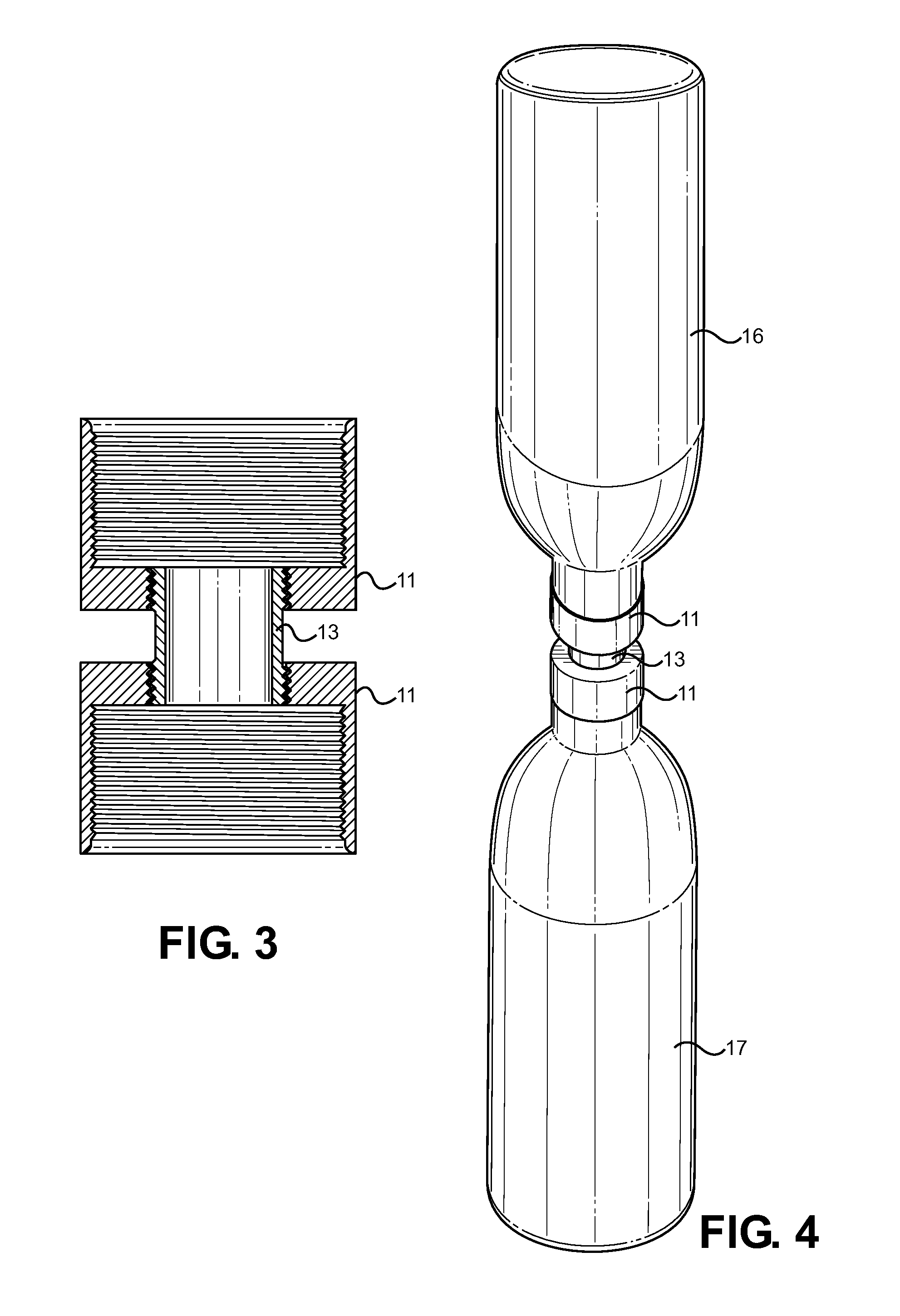

[0033]Referring now to FIG. 3, there is shown a cross section view of the present invention, wherein the first and second caps 11 are connected via the central fluid transfer channel 13 to create a pathway for fluid between joined containers. In an exemplary embodiment, both caps 11 provide a first opening that employs a threaded connection to their respective containers, while providing a second opening having a threaded connection adapted to join the caps together via the threaded connection of the central channel 13. The threaded connections ensure an air tight and secure connection, whereafter the elements may be disengaged from the containers and separated into individual components for cleaning and storage. The separatabliity of the elements further allows different sized caps 11 to be mated, providing for connection of dissimilar containers.

second embodiment

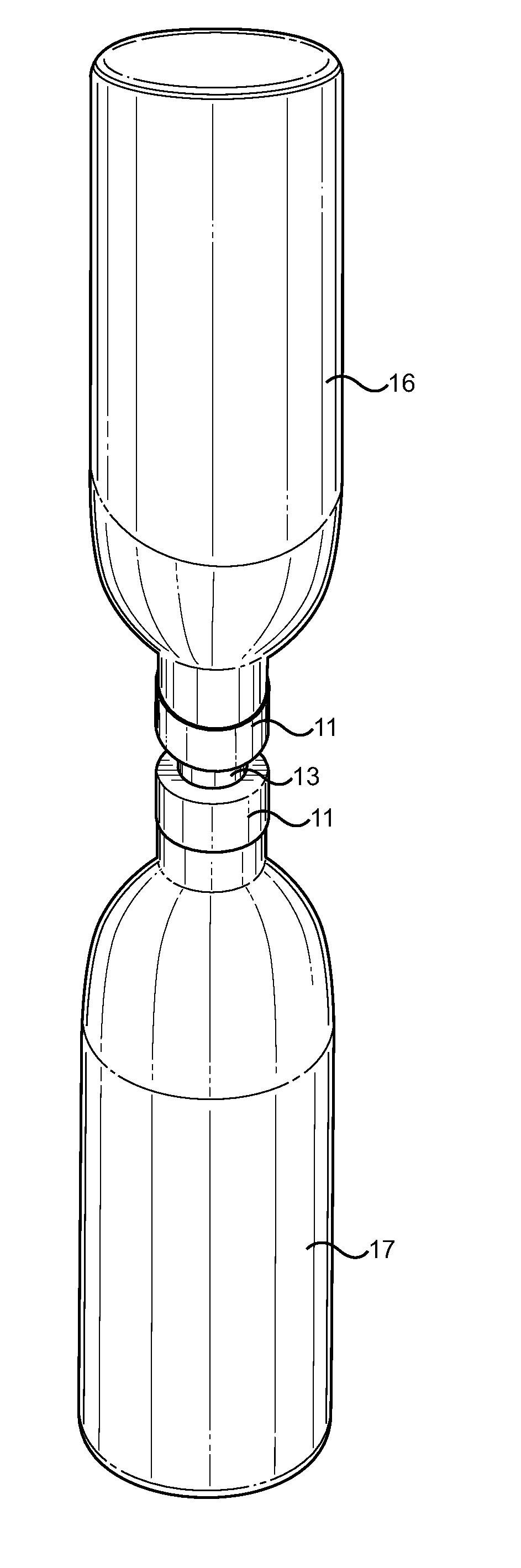

[0034]the present invention provides a cap having an integrated channel in place of its second opening. This provides two distinct styles of caps: a first style wherein a channel is provided, and a second style wherein an opening is provided adapted to connect to a channel. This configuration reduces part count and reduces the steps for setting up and utilizing the device. Further, the first style cap having the integrated channel may stay connected to a larger container of condiment fluid, wherein this larger container is utilized to refill and dispense fluid to smaller, more individualized containers for use by consumers.

[0035]Within the channel of either embodiment of the present invention may be provided a valve that controls the flow of fluid and air from the attached container. This valve is controlled from the exterior of the channel and allows a user to attach the channel (or cap having an integrated channel) to a container desired to be emptied. When the valve is in a close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com