Chuck and lock system with extendable brace for preventing falling of flatbed truck loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]In the description that follows, dunnage is assumed to be timber with a 4 by 4 crossection or using two 2 by 4 pieces adjacent to each other as is common in the USA. Dimensions to accommodate these common timber sizes are presented. In other jurisdictions, similarly sized timber of common metric dimensions would be used as dunnage and as stakes. Therefore the extendable brace and the chuck and lock units for those regions may deviate slightly from the dimensions discussed here.

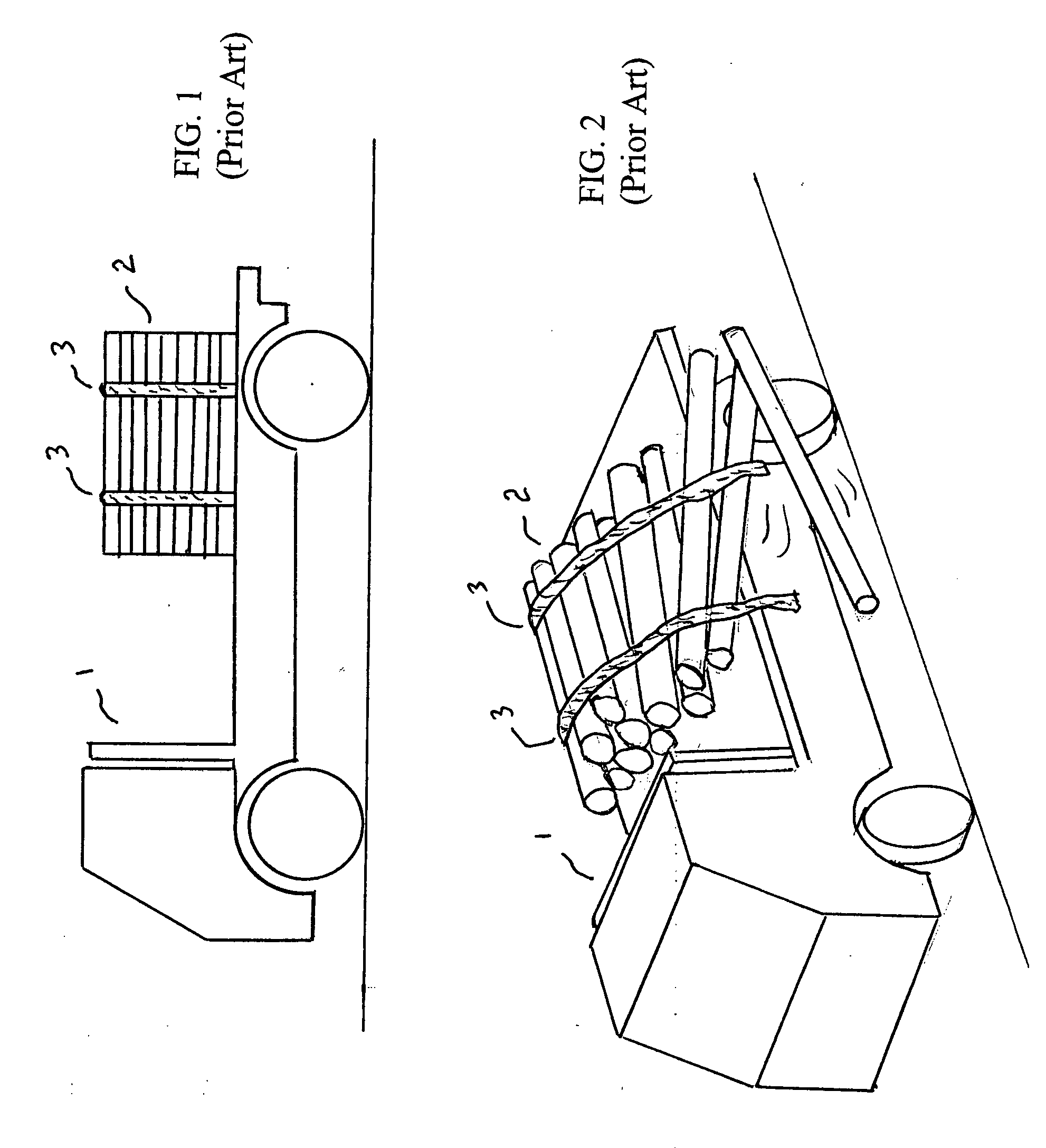

[0036]The problems of conventional load removal from flat bed platform trucks is shown in prior art drawing FIGS. 1 and 2. For example, prior art FIG. 1 shows a flatbed truck 1 with a load 2 clamped down by two straps 3 as is common recommended practice. Prior art FIG. 2 shows an accident in process as the straps 3 are detached from one side and load 2 is shifting and tumbling off the side of truck 1.

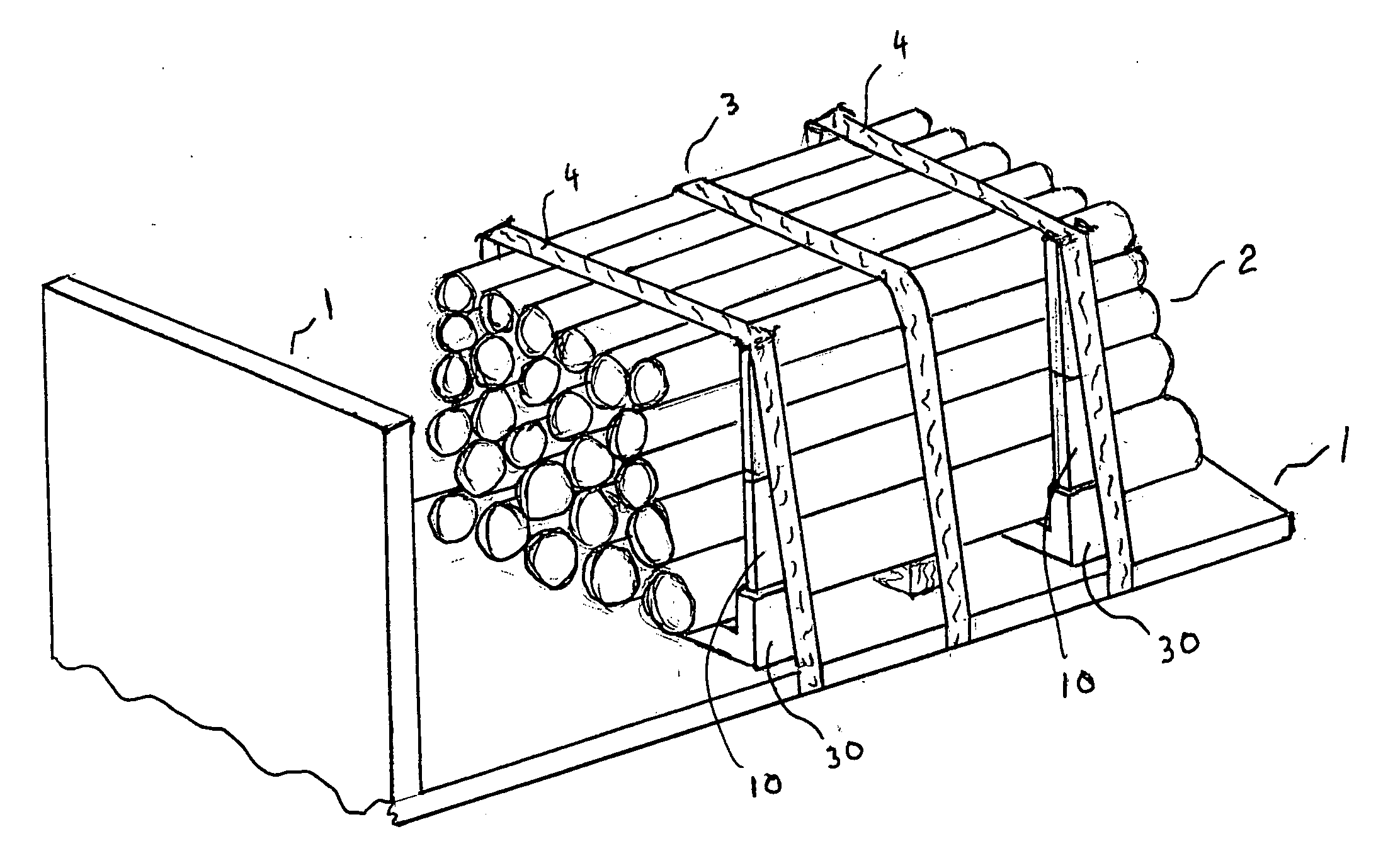

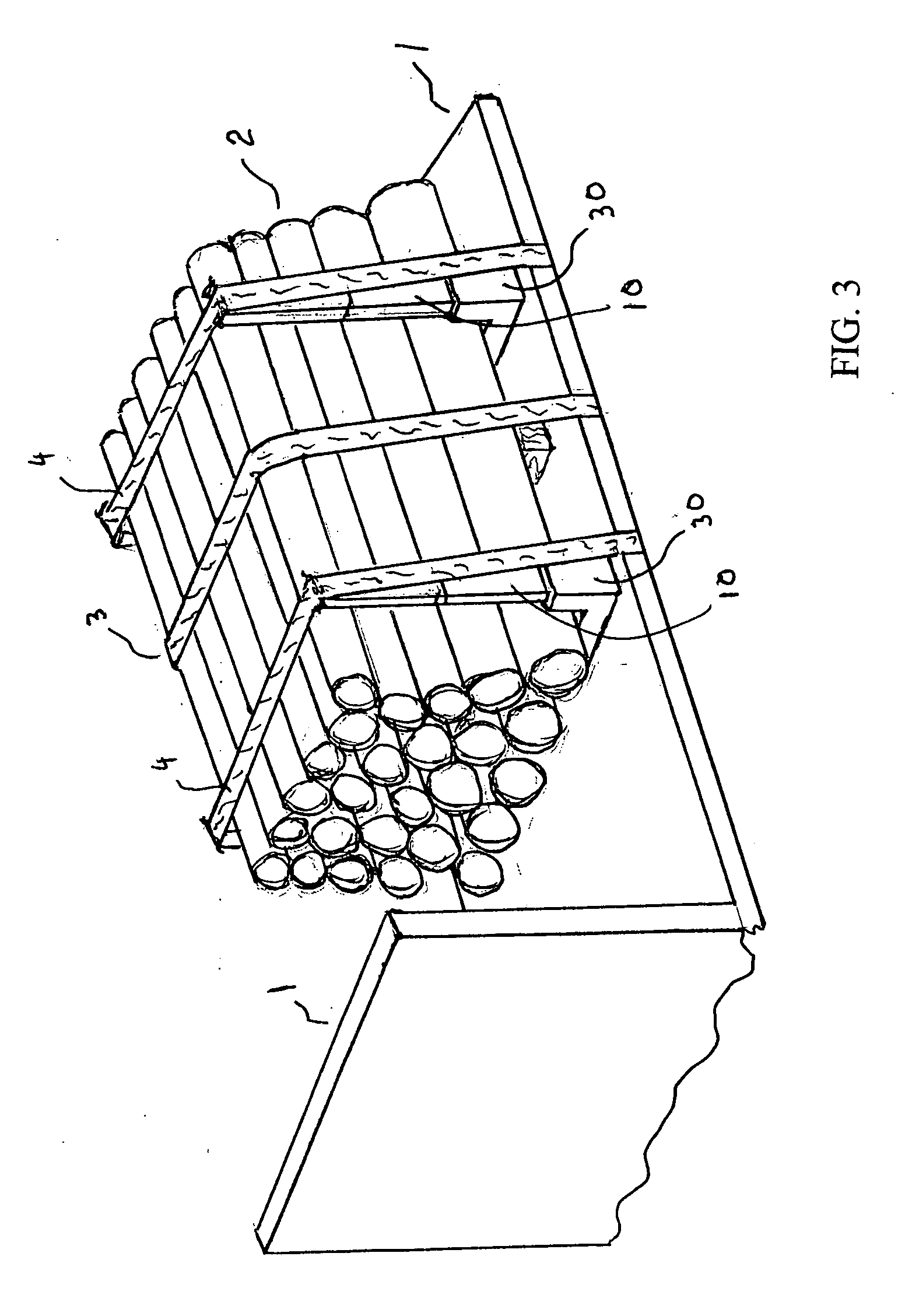

[0037]In contrast to the dangers and problems associated with the prior art depicted in FIGS. 1 and 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com