Modular chiller heater reversing/non-reversing conversion apparatus and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

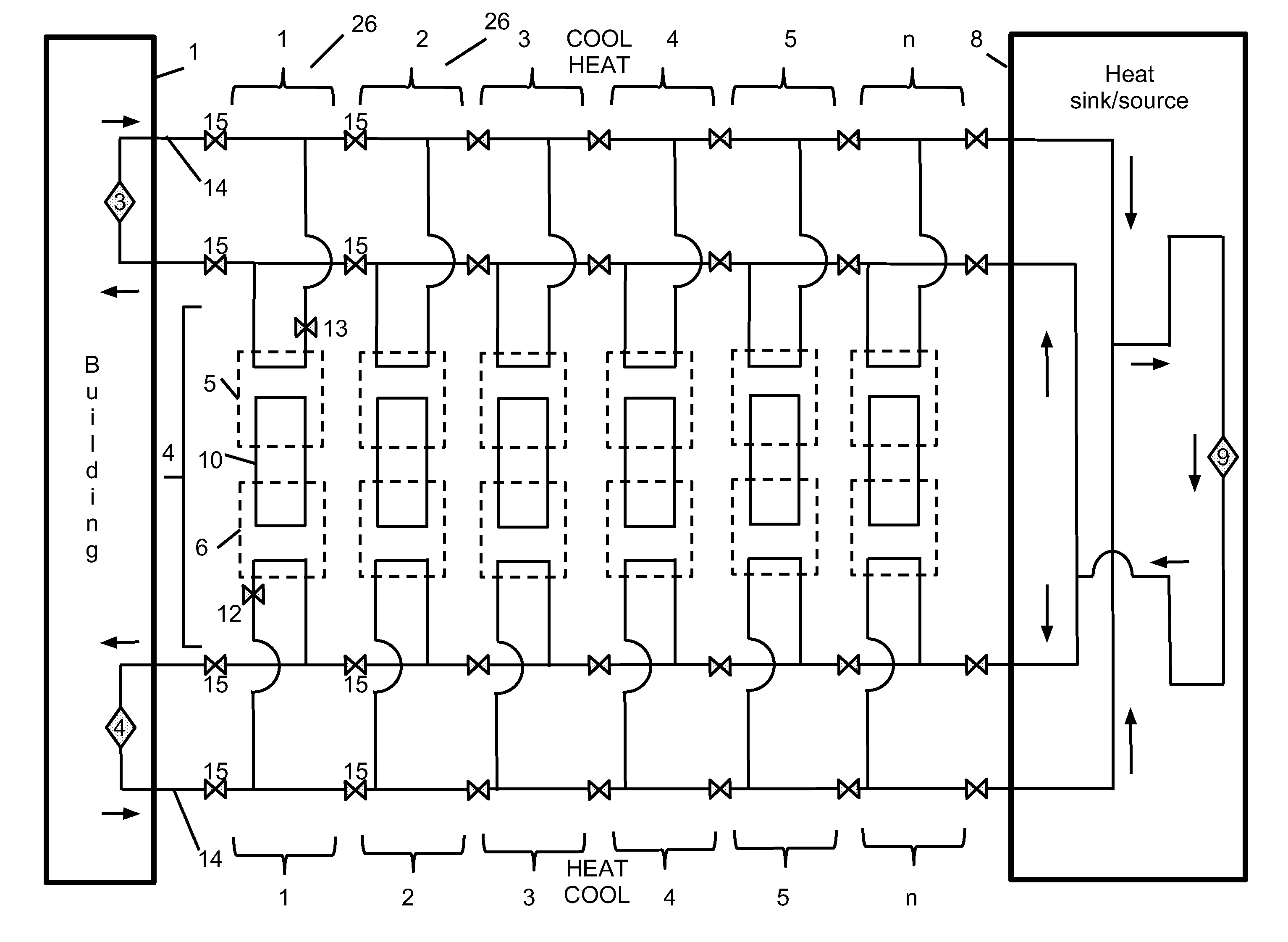

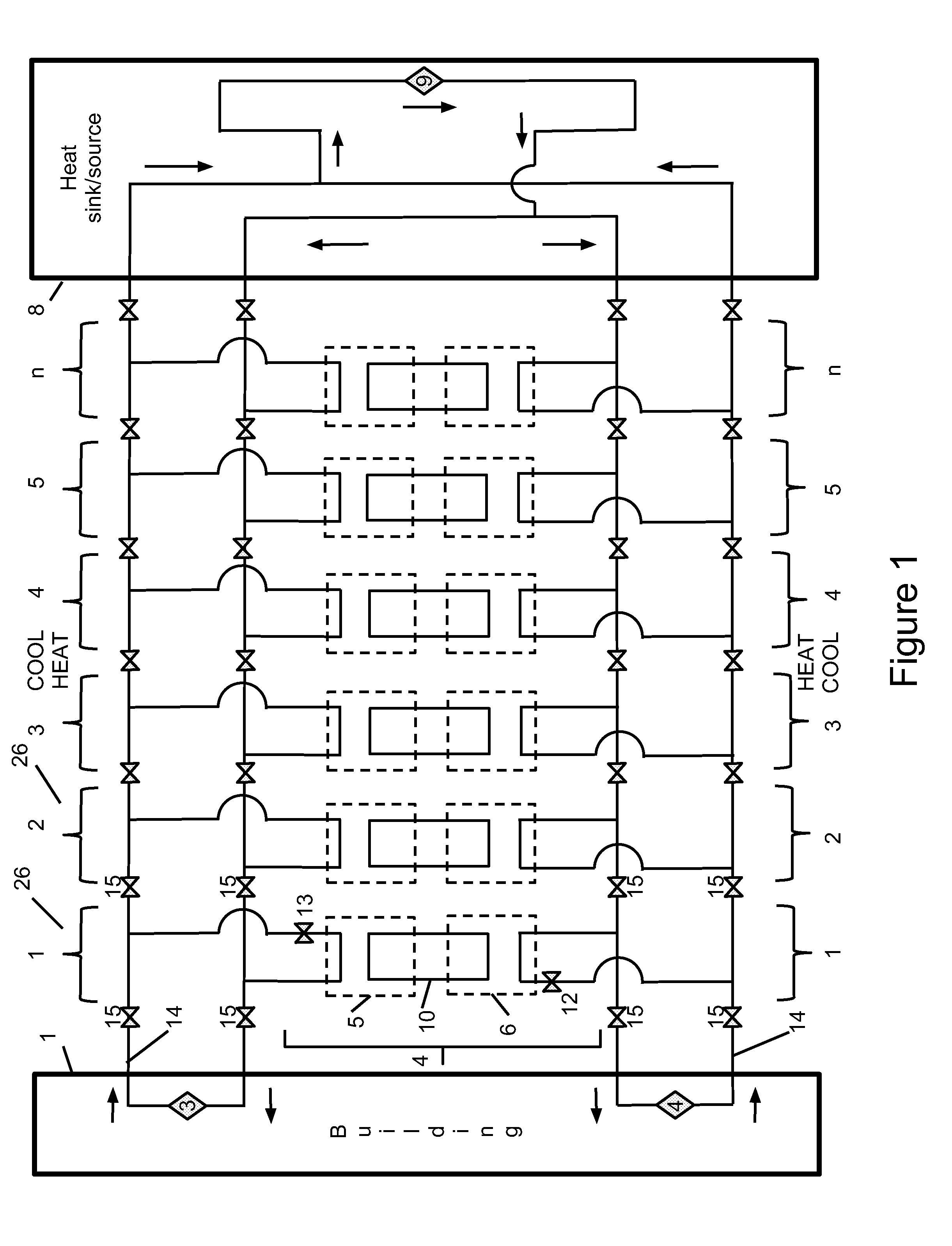

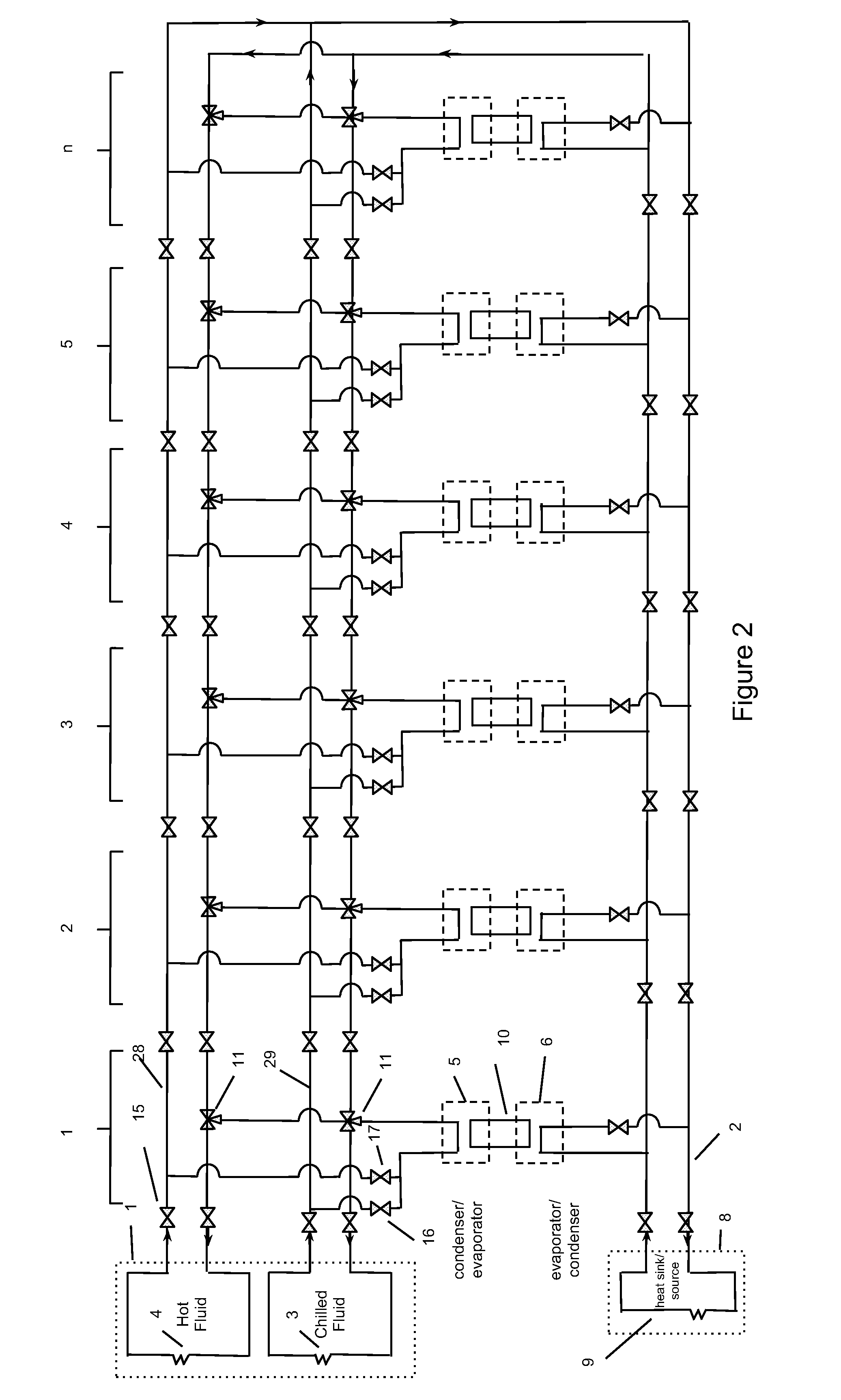

[0017]Following is a listing of elements of the invention.[0018]1. Building to be conditioned[0019]2. Second side building fluid manifold[0020]3. First side building heat exchanger[0021]4. Second side building heat exchanger[0022]5. First side evaporator / condenser[0023]6. Second side condenser / evaporator[0024]7. Alternate chilled fluid / heat sink / source three way valve[0025]8. Ground / water heat sink / source[0026]9. Ground / water heat sink / source heat exchanger[0027]10. Reversing refrigerant working fluid loop[0028]11. Alternate heated fluid / chilled fluid three way valve[0029]12. Second side reversible chiller heater isolation valve[0030]13. First side reversible chiller heater isolation valve[0031]14. Building conditioning fluid loop[0032]15. Virtual moveable endcap building fluid isolation valves[0033]16. Chilled fluid isolation valve[0034]17. Heated fluid isolation valve[0035]18. Heated fluid bypass circuit[0036]19. Heated fluid bypass circuit isolation valve[0037]20. Heated fluid bu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap