Double-faced woven fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The present invention will now be described with some preferred embodiments thereof and with reference to the accompanying drawings. For the purpose of easy to understand, elements that are the same in the preferred embodiments are denoted by the same reference numerals.

[0022]The present invention provides a double-faced woven fabric that presents different textures and colors at two opposite faces thereof. The double-faced woven fabric of the present invention is obtained mainly by weaving warp threads and weft threads of different colors, such that two weave units located in two different planes are mutually connected via a plurality of stitching points. The double-faced woven fabric of the present invention can be woven using general weaving materials and weaving machines without any particular restriction thereto.

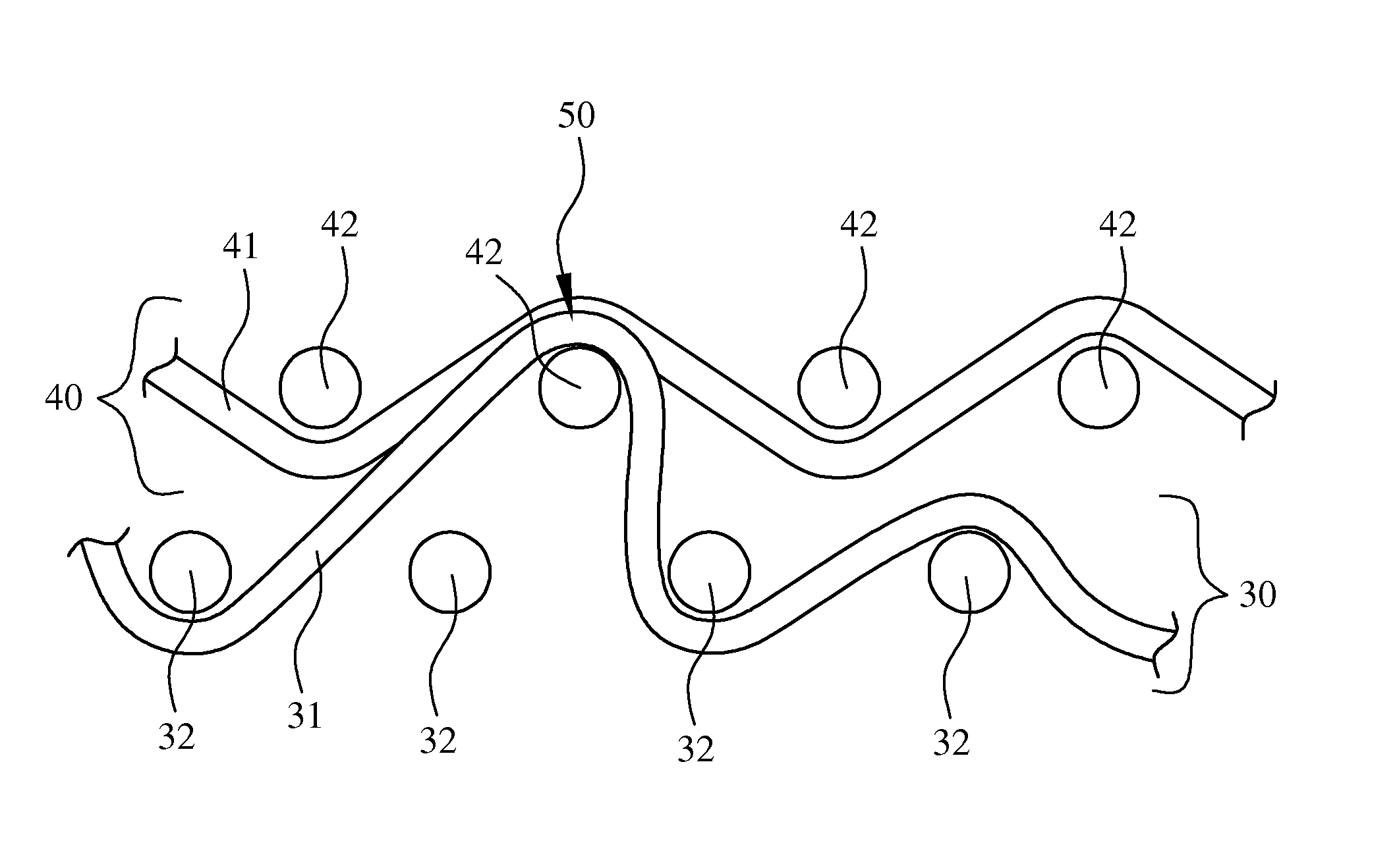

[0023]Please refer to FIG. 4. The double-faced woven fabric according to the present invention includes a first weave unit 30, a second weave unit 40, and a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com