Heat dissipation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

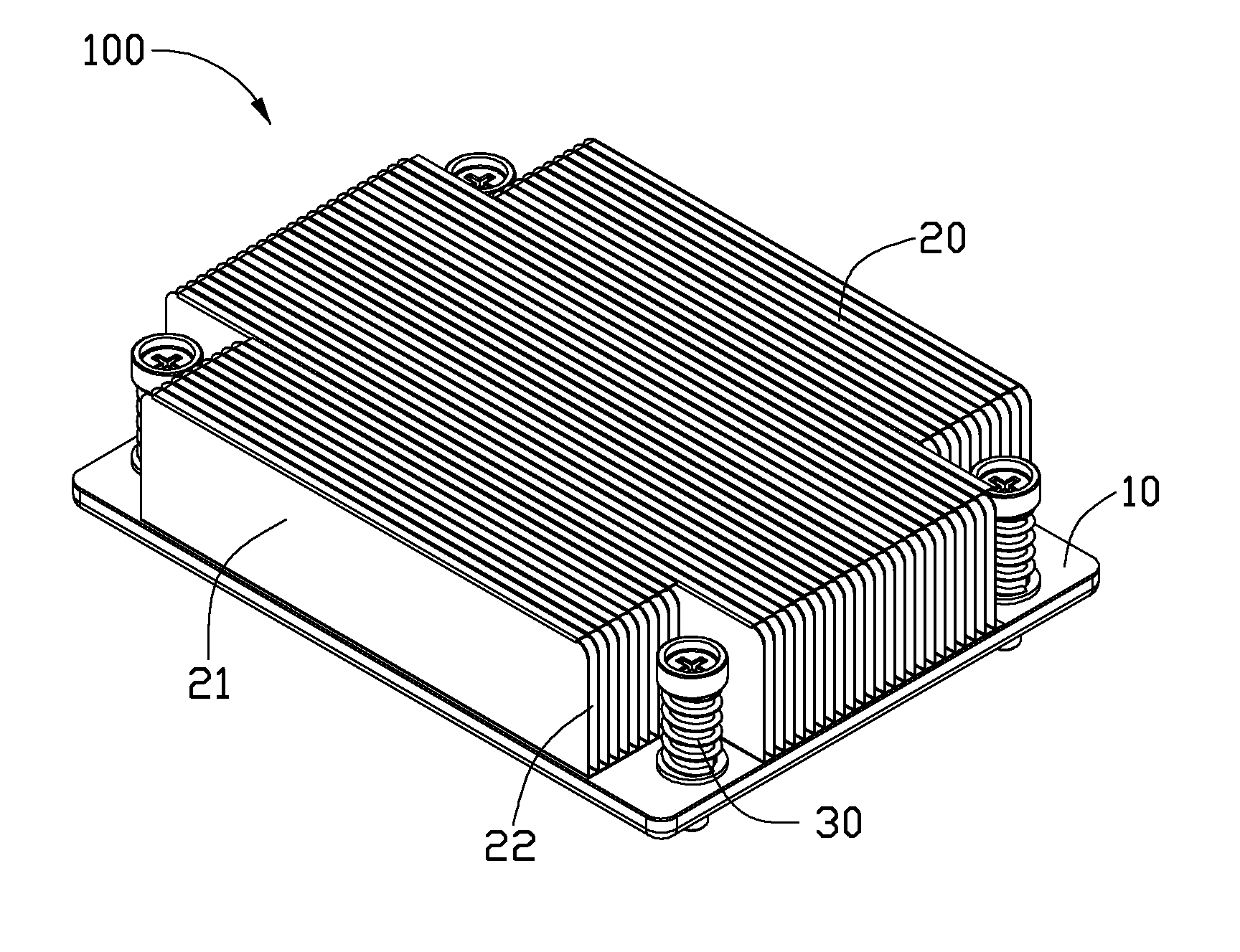

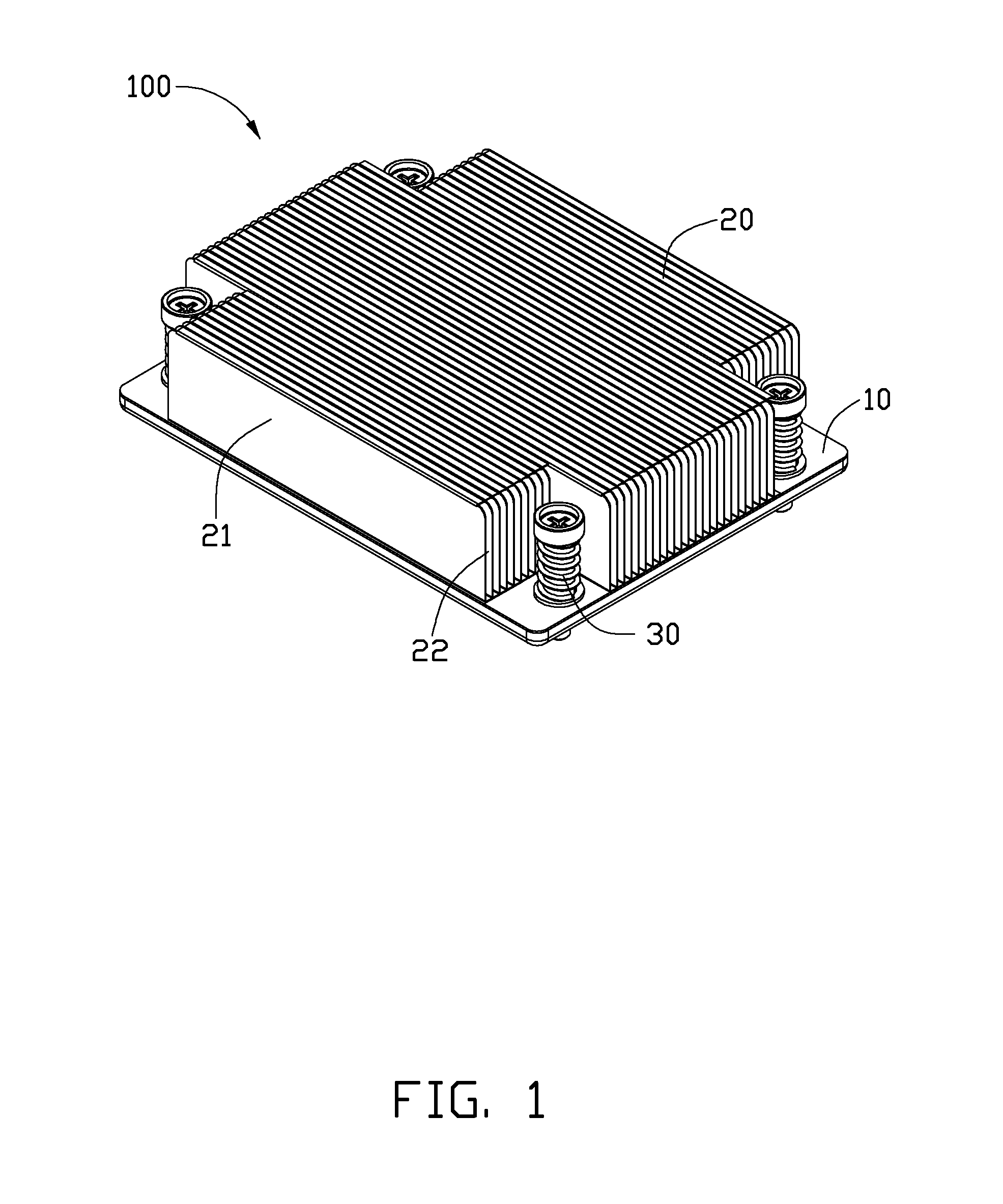

[0009]Referring to FIG. 1, a heat dissipation device 100 is shown. The heat dissipation device 100 includes a base 10 and a fin group 20 mounted on the base 10. The heat dissipation device 100 is used to dissipate heat generated from a heat-generating component (not shown).

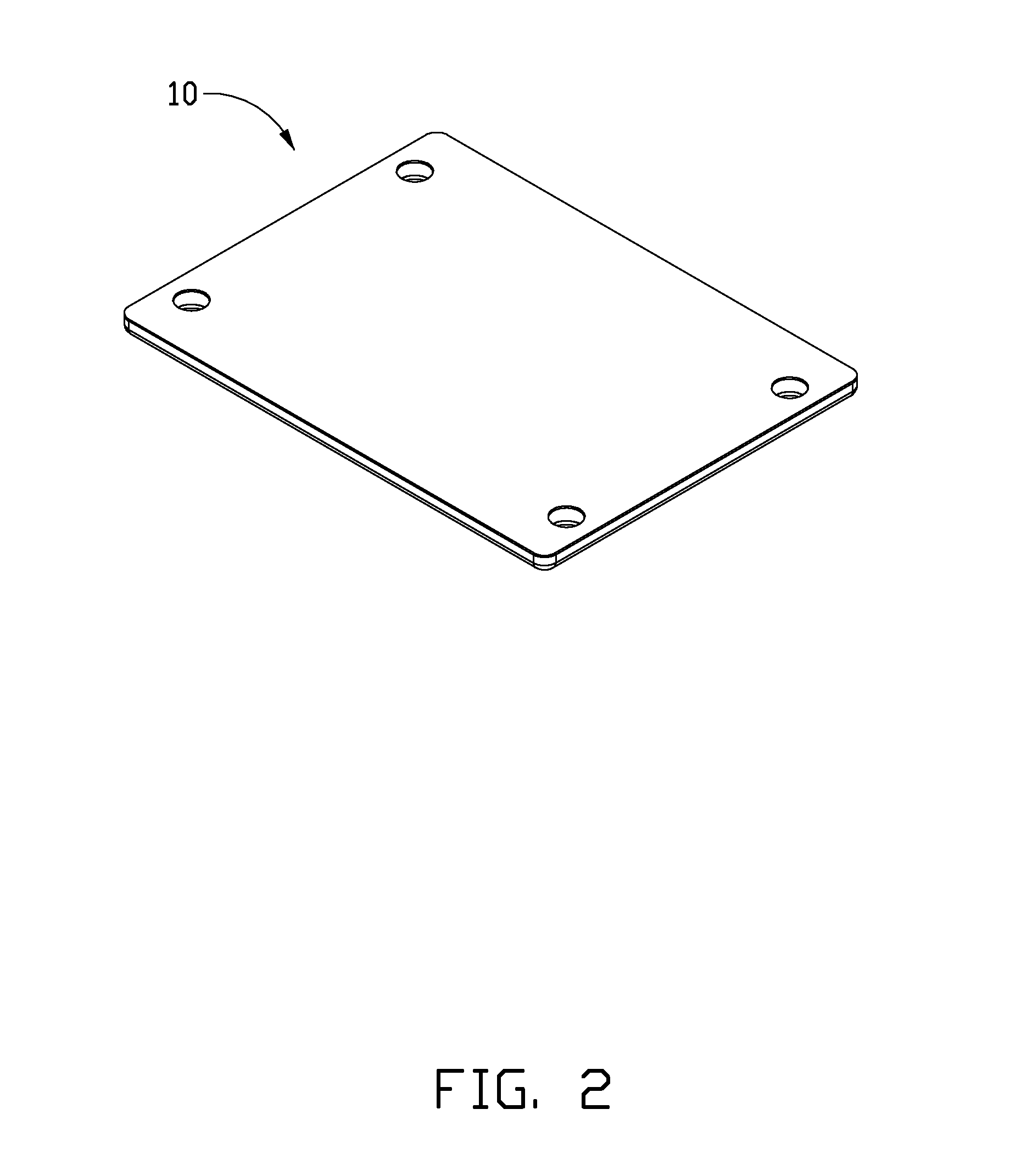

[0010]Referring also to FIGS. 2-3, the base 10 is rectangular and thin, and includes a container 16, a heat pipe 14, and two supporting members 13. The container 16 receives the supporting members 13 and the heat pipe 14 therein.

[0011]The container 16 is made of heat conductive material and includes a rectangular baffle plate 11 and a cover 12 engaging with the baffle plate 11 to define a receiving chamber 15 therebetween. Four through holes 111 are respectively defined in corners of the baffle plate 11. The cover 12 includes a rectangular supporting plate 121 and four sidewalls 122 extending from edges of the supporting plate 121 to the baffle plate 11. The baffle plate 11 connects top ends of the sidewalls 122. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com